Water-free non-flushing closestool

A flush-free toilet technology, applied in the field of sanitary ware, to achieve the effect of isolating odor, saving water resources, and avoiding the spread of disease sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

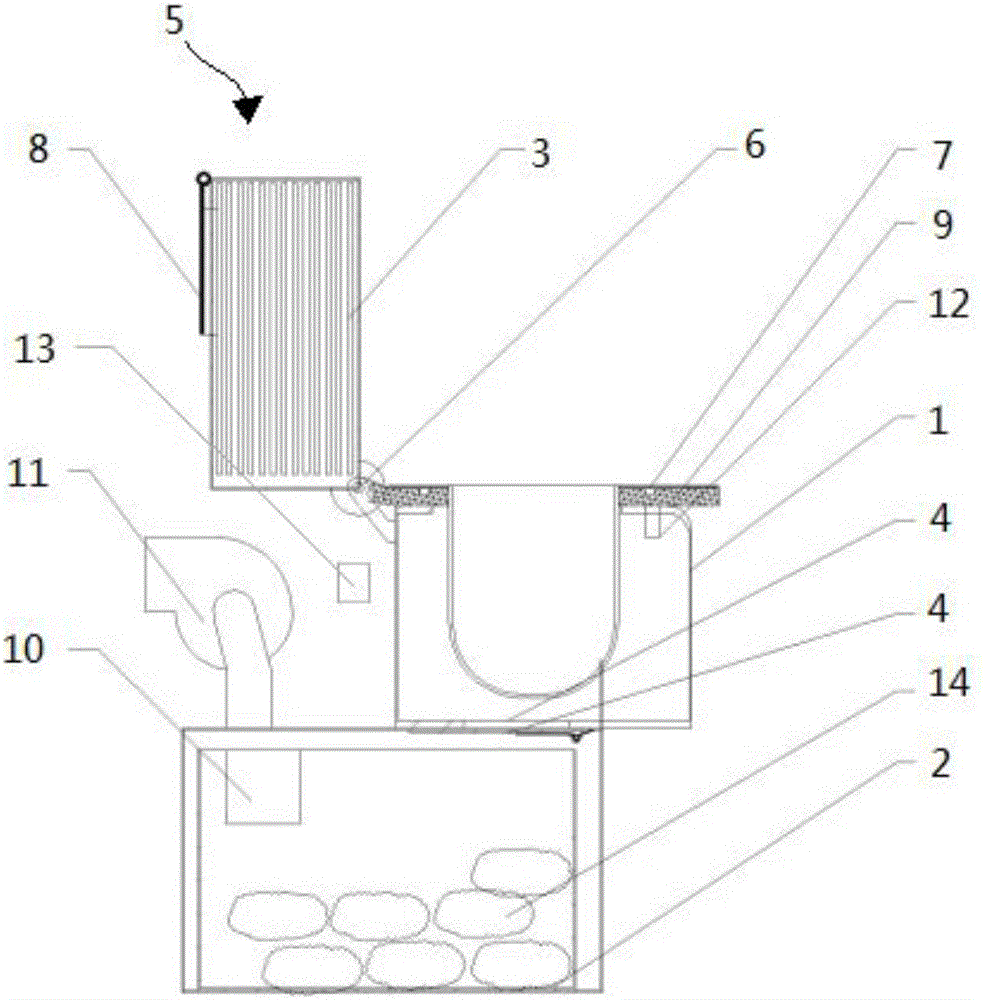

[0015] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0016] Such as figure 1 As shown, the present invention provides a waterless flush-free toilet, including a storage box 2, a toilet body 1, and a toilet ring 8 arranged above the toilet body 1; the toilet body 1 is provided with a storage bag for storing feces 3. A communication channel (not shown in the figure) is provided between the bottom of the toilet body 1 and the storage box 2, and a one-way valve plate 4 is provided on the communication channel, and the storage bag 3 containing feces passes through The one-way valve plate 4 falls into the storage box 2 to form bagged feces 14 .

[0017] The anhydrous free-flush toilet provided in this embodiment also includes a storage bag feed box 5, a rotating mechanism 6, and a fixing mechanism 7; the storage bag feed box 5 is provided with a storage bag compactor 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com