Novel horizontal tube type sedimentation pond

A technology of horizontal pipes and sedimentation tanks, which is applied in the direction of sedimentation separation, settling tanks, feeding/discharging devices of settling tanks, etc. It can solve the problems of discounted clarification capacity, inconvenient processing, difficult manufacturing and high production costs, and achieves guaranteed The effect of mud discharge, simple and reasonable design, and convenient processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

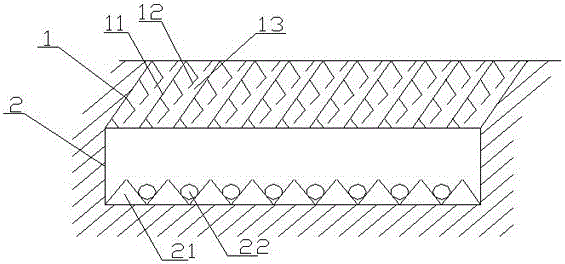

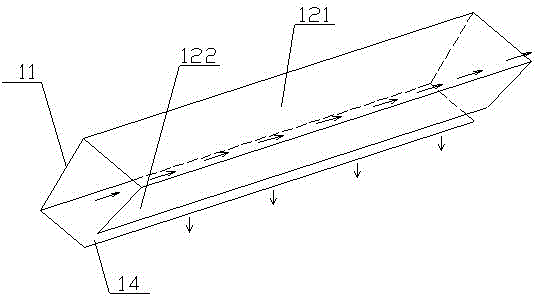

[0036] Such as figure 1 , figure 2 As shown, the upper sedimentation separation device 1 includes several parallel horizontal pipe units and sludge slides 13 formed between two adjacent horizontal pipe units. At least one of the two ends of the sludge slides 13 is closed, so that the sludge slides 13 is a still water area, which is conducive to sludge settlement. The horizontal pipe unit includes a sloping plate 11 and several partitions 12 arranged at intervals on the lower side of the sloping plate 11. When the sloping plate 11 is processed and connected with the partition 12, it is more convenient, and it is only necessary to fix the sloping plate 11 and the partition 12 in sequence. The partition plate 12 is a V-shaped plate whose cross-section is formed by the plate surface A121 and the plate surface B122, and the opening faces the inclined plate. The plate surface A121 is arranged on the side of the inclined plate 11, between the plate surface A121 and the plate surfac...

Embodiment 2

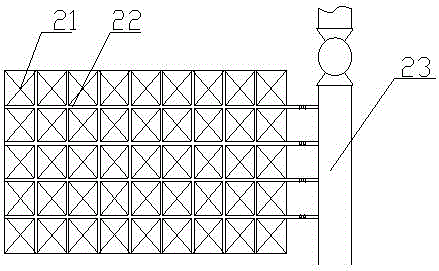

[0040] Such as Figure 8 As shown, on the basis of Example 1, the bottom of the sedimentation tank is funnel-shaped, and the angle between the side wall of the bottom of the tank and the horizontal plane is 45-75 degrees, and the sludge discharged from the upper sedimentation separation device 1 is directly collected into the sedimentation tank The bottom of the pool is connected to the sludge discharge supervisor 23, and the sludge discharge supervisor 23 has a sludge discharge valve 24. When the sludge accumulates to a certain extent at the bottom of the pool, the sludge discharge valve 24 is opened, and the sludge is discharged from the sedimentation tank.

Embodiment 3

[0042] Such as Figure 9 As shown, on the basis of Embodiment 1 or 2, several groups of horizontal pipe units and sludge slideways form a main body with a quadrangular cross-section, and the outside of the main body is covered with a formwork 6 with a quadrilateral cross-section that fits with it. The frame 6 can be a prismatic frame with a quadrangular cross-section, or can be made of grid material to facilitate mud discharge, and make the bottom of the sludge slideway 13 a continuous mud discharge groove; Set in parallel to form a sedimentation and separation device, and produce scattered sedimentation and separation devices in a modular form, which is convenient for transportation and installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com