Roll painting device and tower drum operational equipment

A technology of roller coating and roller coating mechanism, which is applied to the device and coating of surface coating liquid, which can solve the problems of manual coating work intensity, low degree of automation, bulky and cumbersome equipment, etc., and achieve compact and convenient structure , Improve work efficiency and reduce the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

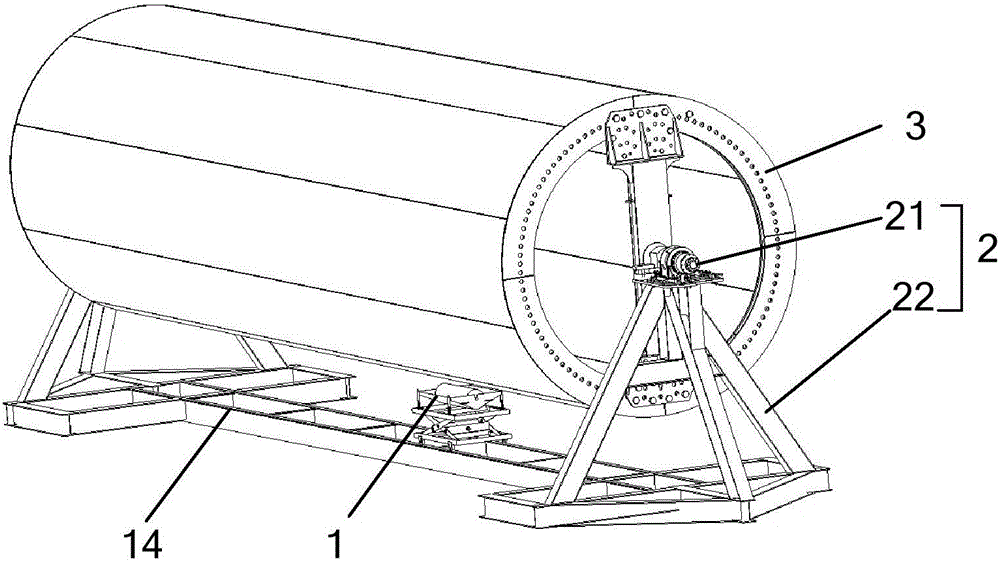

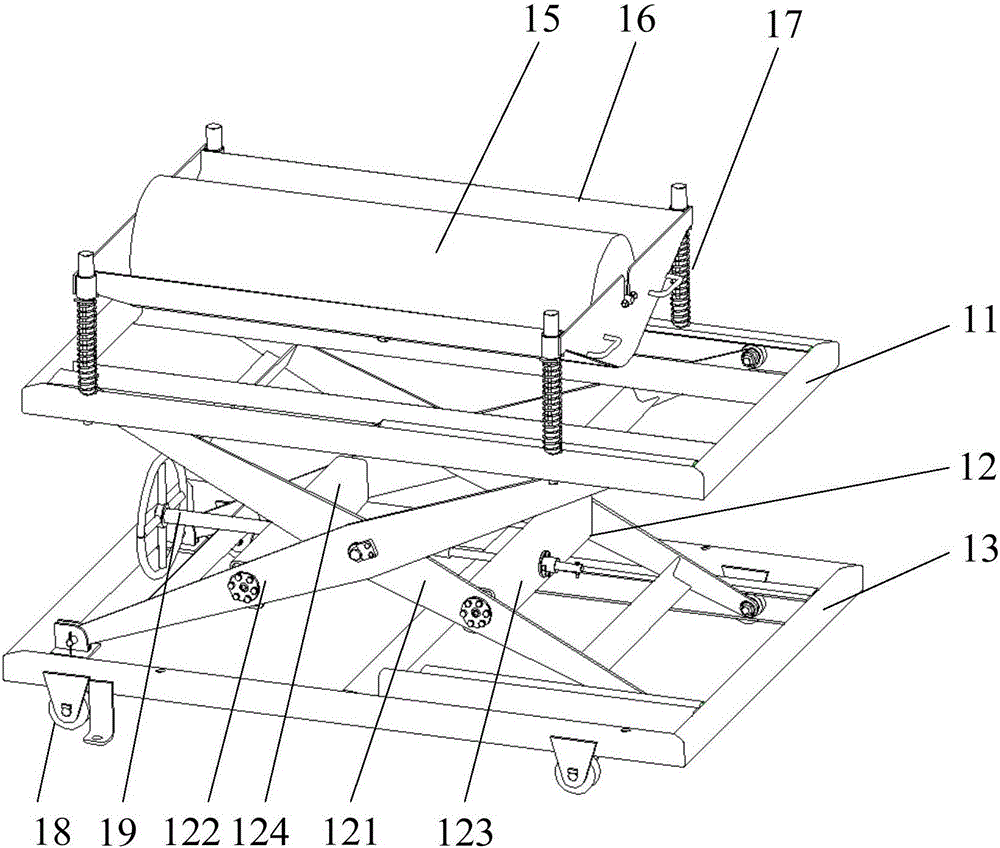

[0031] to combine figure 1 , figure 2 As shown, the roller coating device provided by the present embodiment one includes a power mechanism 2 and a roller coating mechanism 1; One is the active part, and the other is the driven part; the power mechanism 2 includes a drive unit 21, the drive unit 21 is used to drive the active part to rotate around its own axis, and the driven part drives the driven part to rotate, thereby realizing automatic rolling. Paint function. The roller coating device is suitable for large-sized objects to be coated, such as tower tubes. The device can not only reduce the working intensity, but also improve the working efficiency and reduce the cost of painting.

[0032] It is worth noting that, for the selection of the driving part and the driven part, it can be flexibly selected depending on the specific size of the object 3 to be coated. When the object to be coated 3 is a large-sized cylindrical object, it is preferable to use the object to be c...

Embodiment 2

[0056] The tower operation equipment provided in the second embodiment includes the roller coating device in the first embodiment. The tower operation equipment provided in the second embodiment can be applied in the roll coating process of wind power towers. The automatic coating of the wind power tower is realized by the roller coating device.

[0057] The coating process of the wind power tower will be described in detail below in combination with the specific structure of the roller coating device.

[0058] combine figure 1 , figure 2 As shown, the roller coating device includes a power mechanism 2 and a roller coating mechanism 1 . Wherein, the roller coating mechanism 1 includes a roller brush 15 for painting the outer peripheral surface of the wind power tower. One of the rolling brush 15 and the wind power tower is a driving part, and the other is a driven part. That is to say, the rolling brush 15 can be flexibly selected as a driven part or a driving part depen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com