Fast batch-out equipment for rolled glasses

A fast and glass technology, applied in the direction of conveyors, conveyor objects, furnaces, etc., can solve the problems of efficiency, cycle, accuracy and failure rate that cannot meet customer needs, large demand for automated plate taking equipment, and improved automation. , achieve the effect of shortening the stacking waiting time, short response time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

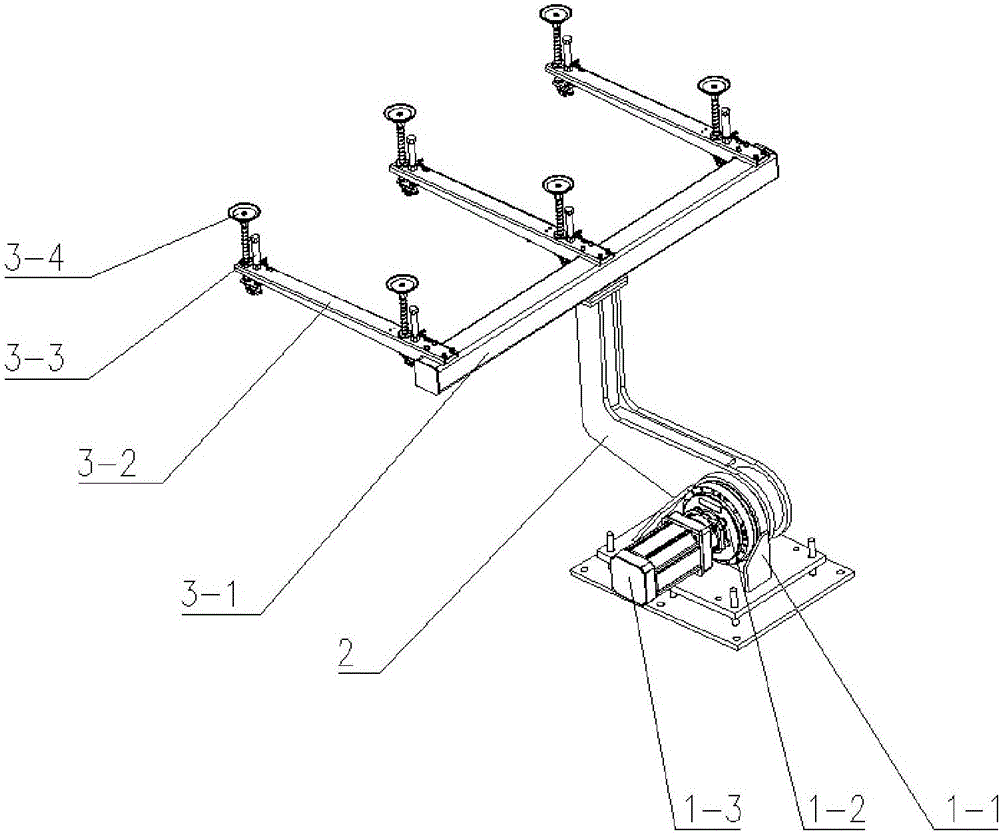

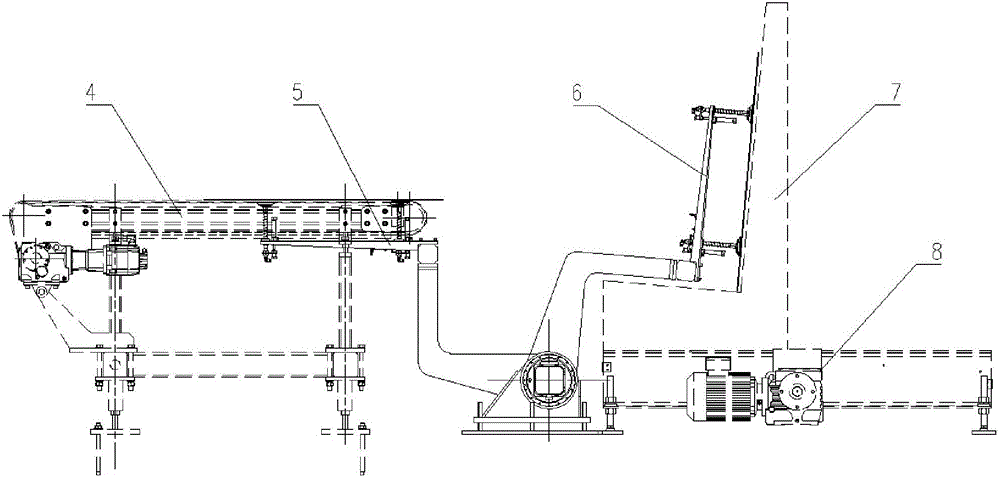

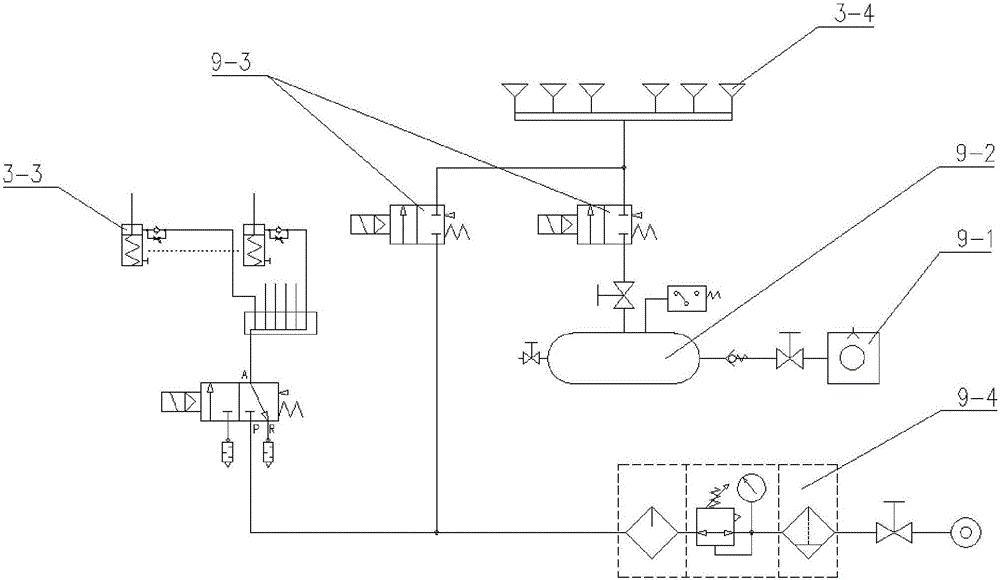

[0015] Referring to the accompanying drawings, a rolling glass fast unloading machine includes an independently set main base 1, a turning arm 2, a suction cup holder 3, an air vacuum system 10 and an electrical control system, and a speed reducer is installed on the main base 1 machine 1-2 and a servo motor 1-3; one end of the turning arm 2 is installed on the output shaft of the reducer 1-2 on the main base 1, and the other end of the turning arm 2 is connected with the suction cup frame 3 ; The suction cup frame 3 includes a crossbeam 3-1, a bending arm 3-2, a plurality of cylinders 3-3 and a suction cup 3-4, the crossbeam 3-1 is fixedly connected with the turning arm 2, and the bending arm 3-2 is fixed on the beam 3-1, and the plurality of suction cups 3-4 are distributed on the bending arm 3-2 for sucking the glass plate. The suction cups 3-4 are driven by the cylinder 3-3 to move back and forth, and the cylinder 3-3 is installed on the bending arm 3-2; the air path vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com