Automatic optical fiber deuterium treatment equipment

A technology for processing equipment and deuterium gas, which is applied in the field of optical fiber, can solve the problems of low production efficiency, low degree of automation, time-consuming and labor-intensive, etc., and achieve the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

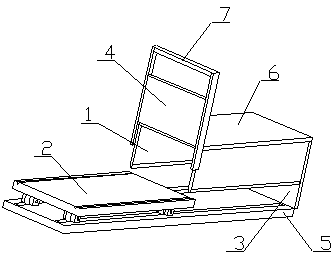

[0032] Such as figure 1 As shown, the automatic optical fiber deuterium gas processing equipment includes a sealed processing chamber, a vacuum pump, a deuterium gas intake pipeline and a controller;

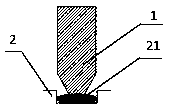

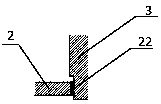

[0033] Such as figure 1 As shown, the sealed treatment chamber includes a workbench 2, two side panels 1, a top cover 6, a front door 4 and a rear panel 3; the two side panels 1, the top cover 6 and the rear panel 3 are fixedly connected to form a front and An open box body with an open bottom, the rear plate 3 and the side plate 1 are fixed together, positioned on the ground and fixed, positioning columns are added to the side plates 1, the workbench 2 is set slidingly on the bottom of the box body, and the front door 4 Sliding up and down in front of the box body, the front door 4 is arranged on a sliding frame 7, and the front door 4 slides up and down along the sliding frame 7, the sliding frame 7 is fixed on the side plate 1, and the sealed treatment chamber is a sealed bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com