A kind of anti-segregation skeleton compact cement-stabilized gravel mixture, its application and paving method

A cement-stabilized gravel and compaction technology, which is applied to cohesive pavement paved on site, buildings, roads, etc., can solve the problem of uneven compaction, the strength of the mixture not reaching the design strength, water damage to the road surface, etc. problems, to achieve significant social and economic benefits, good anti-scourability, and reduce health care costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

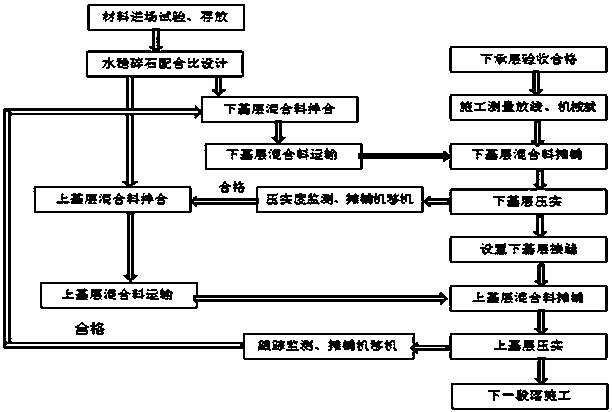

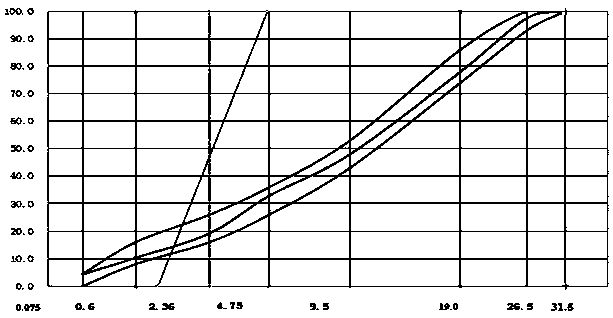

[0042] [mixture] as attached figure 1 The given synthetic gradation curve, the aggregate composition ratio is:

[0043] 20-30mm gravel 14Kg, 10-20mm gravel 40 Kg, 5-10mm gravel 16 Kg, 0-5mm stone powder 30 Kg;

[0044] The passing percentage of each sieve hole is:

[0045] 31.5mm 100%; 26.5mm 97.5%; 19mm 78.0%;

[0046] 9.5mm 48.0%; 4.75mm 32.9%; 2.36mm 19.2%;

[0047] 0.6mm 10.3%; 0.075mm 5.5%.

[0048] The cement is measured as 4.0% (weight percentage) of the mineral material, the optimum water content is 5.2%, and the maximum dry density is 2.440g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com