A thermal processing method for preparing multi-scale and multi-configuration dual-phase titanium alloy structure

A titanium alloy, multi-configuration technology, applied in the field of hot processing of dual-phase titanium alloys, can solve the problems of complex processing process, unstable metastable phase, unfavorable refined structure, etc., and achieve simple hot processing technology and machinability. Good, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

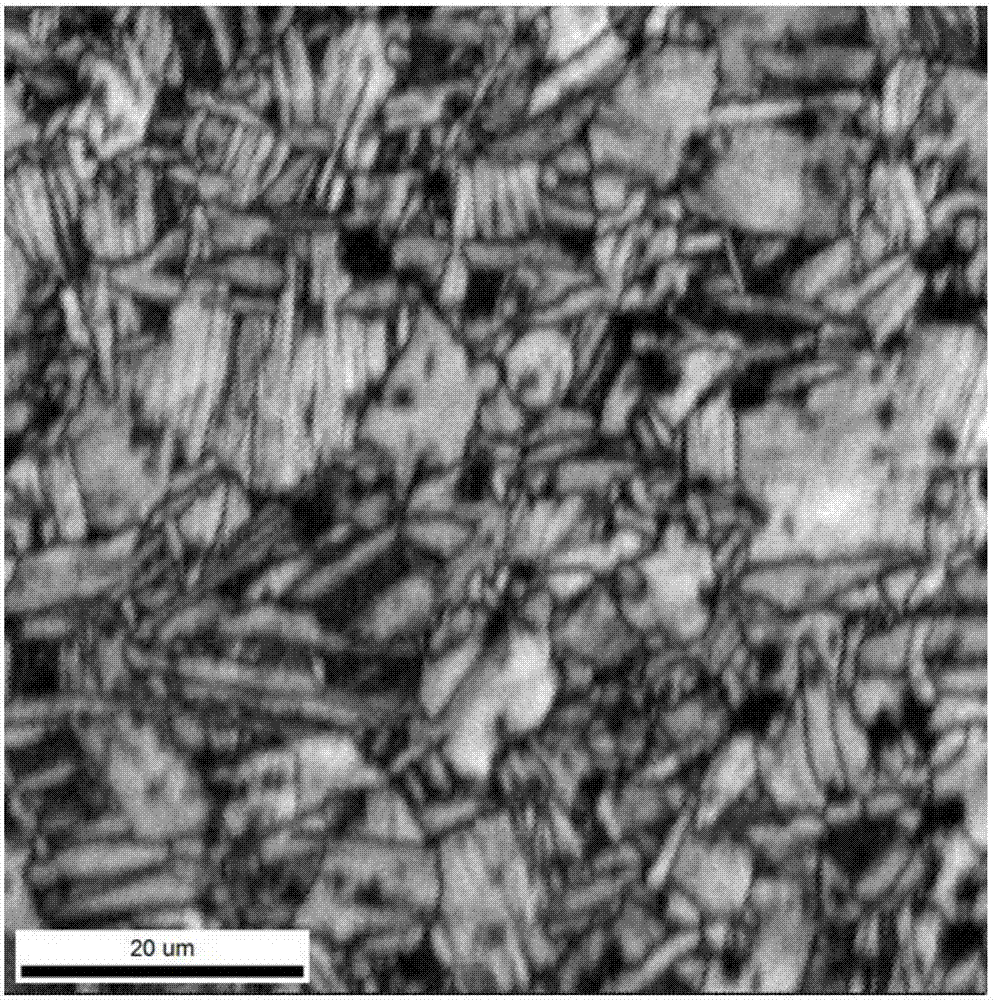

[0023] In an environment with argon as protective gas, a TC4 dual-phase titanium alloy sheet with a thickness of 2mm was heated to 950°C at 25°C / s and kept for 40s, so that the proportion of the two-phase α phase accounted for 60%, and the intergranular β phase accounted for 60%. 40%, and then quickly sent to the rolling mill for rolling, and the compression deformation with a reduction of 1mm was quickly carried out, and the deformation strain rate was 10-12s -1 , After the thermal deformation is completed, spray water to cool, and cool the titanium alloy plate from 950 ° C to room temperature at a cooling rate of 200-250 ° C / s. figure 1 The microstructure diagram of TC4 titanium alloy after deformation. The width of the α lath is measured to be about 0.29 μm, and it is found that the titanium alloy has a better microstructure refinement effect and has a multi-scale and multi-configuration structure.

Embodiment 2

[0025] In the environment with argon as the protective gas, the TC4 dual-phase titanium alloy sheet with a thickness of 2mm was heated to 900°C at 30°C / s and kept for 30s, so that the proportion of the two-phase α phase accounted for 70%, and the intergranular β phase accounted for 70%. 30%, and then quickly sent to the rolling mill for rolling, and the compression deformation with a reduction of 1mm was quickly carried out, and the deformation strain rate was 13-15s -1 , After the thermal deformation is completed, spray water to cool, and cool the titanium alloy sheet from 900 °C to room temperature at a cooling rate of 250-300 °C / s. figure 2 The microstructure diagram of TC4 titanium alloy after deformation. The width of α lath was measured to be about 0.28 μm, and it was found that the effect of microstructure refinement of titanium alloy also existed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com