Production process and equipment for three-component composite hollow viscoelastic fiber with specially-shaped section and product thereof

A technology of special-shaped section and production process, applied in fiber processing, spinneret assembly, fiber chemical characteristics, etc., can solve the problems of releasing toxic and harmful substances, complicated production process, unfavorable environmental protection, etc. The effect of high elasticity, high bulk, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

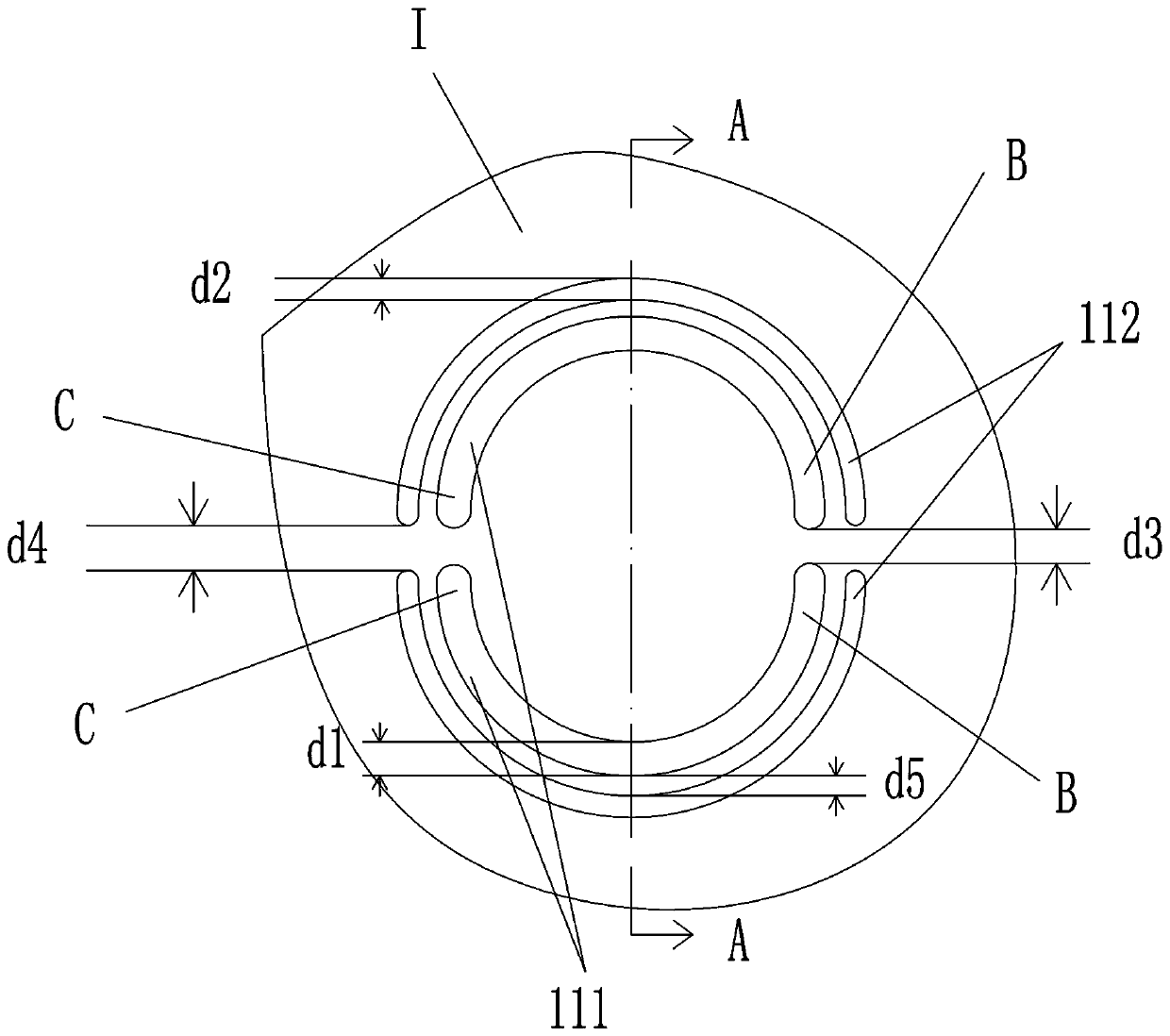

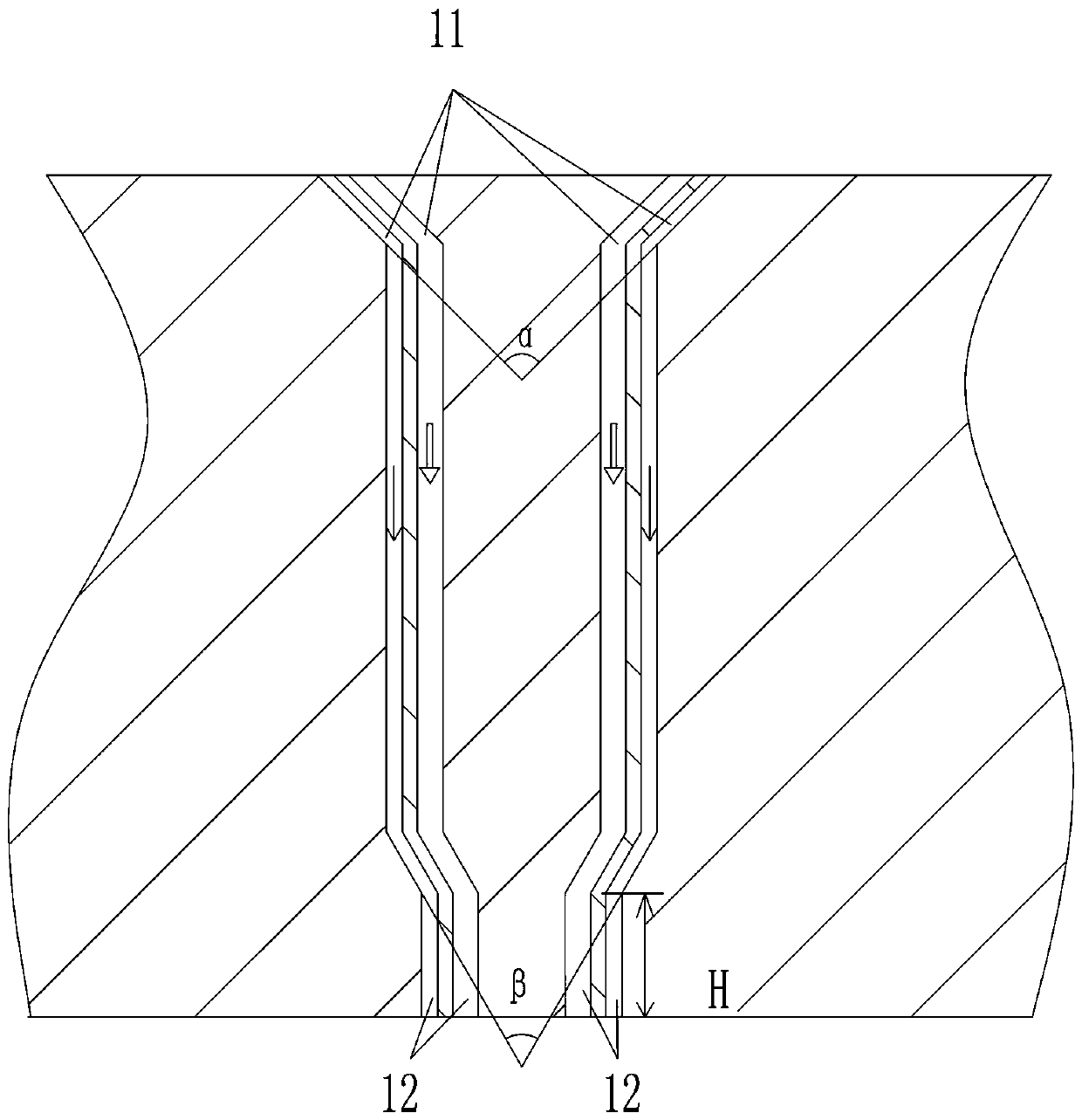

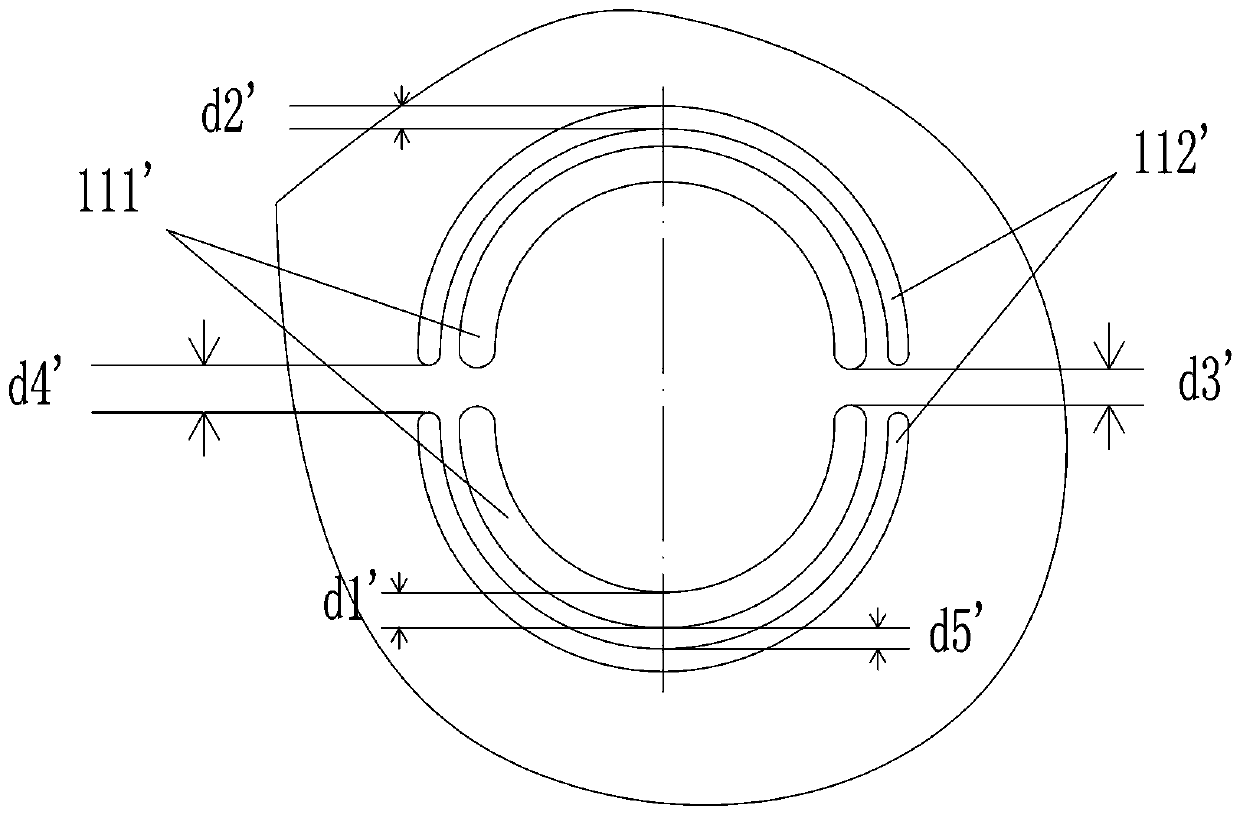

[0022] Such as Figure 1 to Figure 4 As shown, several spinneret holes 1 are evenly distributed on the spinneret 10 of the present invention for producing composite hollow viscoelastic fibers with three-component special-shaped cross-section, and the spinneret holes 1 include guide holes 11 and micropores 12 that penetrate up and down. , the cross-sections of the guide hole 11 and the microhole 12 are composed of two inner arc-shaped waist holes (111, 111') and two outer arc-shaped waist holes (112, 112'), and the two inner arc waist holes The waist holes (111, 111') are symmetrically arranged and the centers of the two inner arc waist holes are close to each other, and the outer arc waist holes (112, 112') are respectively located at the The outer side is arranged parallel to the arc of the adjacent inner arc-shaped waist hole (111, 111...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com