Nano anion functional material for fabric in automobile and preparation method of nano anion functional material

A nano negative ion and functional material technology, applied in the field of negative ion functional materials and its preparation, can solve the problems of developing negative ion automotive interior fabrics and other problems, and achieve the effect of stable performance, long-lasting effect, and elimination of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

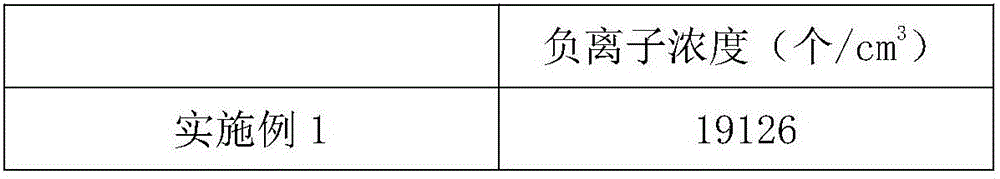

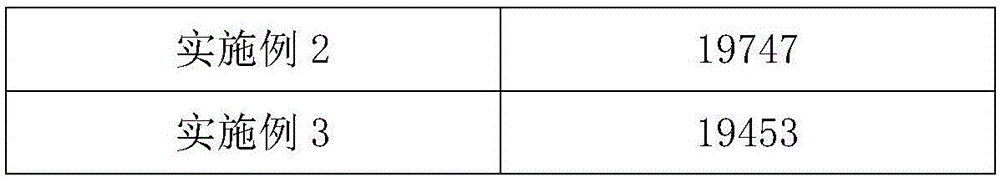

Examples

Embodiment 1

[0015] A nano-anion functional material for automotive interior fabrics, made of the following weight (kg) of raw materials: 25 green shoushi, 15 serpentine, 30 coral fossils, 20 rectorite, 10 fluorite, 14 imonite mixed layer clay , perlite 9, brucite 11, coconut shell activated carbon 5, asbestos powder 5.

[0016] A kind of preparation method of nano anion functional material for automobile interior fabric, comprises the following steps:

[0017] (1) Mix chrysanthemum, serpentine, coral fossils, rectorite, fluorite, illite mixed layer clay, perlite, and brucite, calcinate at 420°C for 5 hours, cool to room temperature, and crush into particle sizes For particles of 25 μm, add an appropriate amount of water and stir to make a suspension with a concentration of 50%, then adjust the pH of the suspension to 9 with a sodium hydroxide solution with a concentration of 15%, treat with microwave for 1 hour, microwave power is 400W, and magnetic oscillation is 1.5 h, the oscillation ...

Embodiment 2

[0021] A nano-anion functional material for automotive interior fabrics, made of the following raw materials by weight (kg): 30 green shoushi, 20 serpentine, 35 coral fossils, 25 rectorite, 15 fluorite, and 18 imonite mixed layer clay , perlite 12, brucite 14, coconut shell activated carbon 8, asbestos powder 7.

[0022] A kind of preparation method of nano anion functional material for automobile interior fabric, comprises the following steps:

[0023] (1) Mix chrysanthemum, serpentine, coral fossils, retortite, fluorite, imonite mixed layer clay, perlite, and brucite, calcined at 450°C for 4 hours, cooled to room temperature, and crushed into particle sizes For particles of 30 μm, add an appropriate amount of water and stir to make a suspension with a concentration of 52%, then adjust the pH of the suspension to 9.2 with a sodium hydroxide solution with a concentration of 15%, treat with microwave for 1.5h, microwave power is 350W, and magnetically oscillate 2h, the oscilla...

Embodiment 3

[0027] A nano-anion functional material for automotive interior fabrics, made of the following raw materials in weight (kg): 35 green shoushi, 25 serpentine, 40 coral fossils, 30 rectorite, 20 fluorite, and 22 illite mixed layer clay , perlite 18, brucite 19, coconut shell activated carbon 10, asbestos powder 10.

[0028] A kind of preparation method of nano anion functional material for automobile interior fabric, comprises the following steps:

[0029] (1) Mix chrysanthemum, serpentine, coral fossils, rectorite, fluorite, illite mixed-layer clay, perlite, and brucite, calcined at 470°C for 3 hours, cooled to room temperature, and crushed into particle sizes For particles of 50 μm, add an appropriate amount of water and stir to make a suspension with a concentration of 55%, then adjust the pH of the suspension to 9.5 with a sodium hydroxide solution with a concentration of 15%, treat with microwave for 2 hours, microwave power is 300W, and magnetic oscillation is 2.5 h, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com