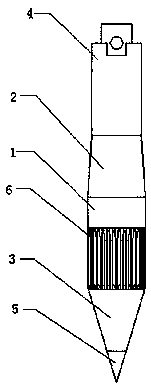

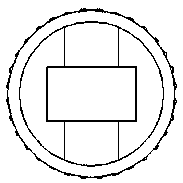

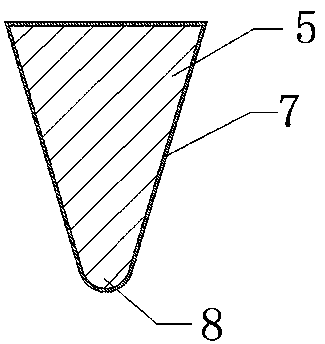

A New Type of Spindle Rammer

A spindle-shaped, rammer technology, applied in the field of new spindle-shaped rammers, can solve the problems of tamper cracks, aggravating the surface of the rammer to form ravines, scratches, cracks, etc., to improve wear resistance and corrosion resistance, extrusion The effect of soil compaction is good and the use cycle is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] Embodiment two is the same as embodiment one, and its difference is that, casting infiltration process comprises the following steps:

[0036] Step 1. Weigh TiC alloy powders with an average particle size of 200 μm and put them into a ball mill, mix them evenly with water glass, flux borax and alcohol to form a paste mixture for later use, wherein the mass content of each component in the TiC alloy powder is: TiC 57% for Mn, 6% for Ni, 2% for Ni, 0.5% for Nb, 5% for Cr, 7% for WC, and the balance is iron. The amount is 5.7% of the weight of TiC alloy powder;

[0037] Step 2, apply the prepared paste mixture evenly in the mold cavity, the coating thickness is 4mm, after the coating is completed, ignite the paste mixture, so that the paste mixture solidifies and adheres in the mold cavity, spare;

[0038] Step 3. Put the mold coated with the mixture into a heat treatment furnace and bake at 250°C for 3 hours, then take it out and air cool;

[0039] Step 4: Melt molten ...

Embodiment 3

[0043] Embodiment three is the same as embodiment one and embodiment two, and its difference is that, casting infiltration process comprises the following steps:

[0044] Step 1. Weigh TiC alloy powders with an average particle size of 235 μm and put them into a ball mill, and mix them evenly with water glass, flux borax and alcohol to form a paste mixture for later use. The mass content of each component in the TiC alloy powder is: TiC is 55%, Mn is 4.5%, Ni is 1.4%, Nb is 0.47%, Cr is 3.6%, WC is 5.8%, and the balance is iron. The amount is 5.7% of the weight of TiC alloy powder;

[0045] Step 2, apply the prepared paste mixture evenly in the mold cavity, the coating thickness is 4mm, after the coating is completed, ignite the paste mixture, so that the paste mixture solidifies and adheres in the mold cavity, spare;

[0046] Step 3. Put the mold coated with the mixture into a heat treatment furnace and bake at 250°C for 3 hours, then take it out and air cool;

[0047] Ste...

Embodiment 4

[0051] Embodiment four is the same as embodiment one, embodiment two and embodiment three, and its difference is that casting infiltration process comprises the following steps:

[0052] Step 1. Weigh TiC alloy powders with an average particle size of 250 μm and put them into a ball mill, mix them evenly with water glass, flux borax and alcohol to form a paste mixture for later use, wherein the mass content of each component in the TiC alloy powder is: TiC is 53%, Mn is 4%, Ni is 1%, Nb is 0.4%, Cr is 3%, WC is 5%, and the balance is iron. The amount of water glass added is 5% of the weight of TiC alloy powder, and the flux is added The amount is 5.7% of the weight of TiC alloy powder;

[0053] Step 2, apply the prepared paste mixture evenly in the mold cavity, the coating thickness is 4mm, after the coating is completed, ignite the paste mixture, so that the paste mixture solidifies and adheres in the mold cavity, spare;

[0054] Step 3. Put the mold coated with the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com