Totally-prefabricated prestressed concrete floorslab structure and prestressed assembling method

A concrete and prestressed technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problem that the fully prefabricated floor slab is difficult to ensure the anti-leakage and connection integrity, and achieve sustainable social and economic development, good resistance The effect of crack resistance and high factory prefabrication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

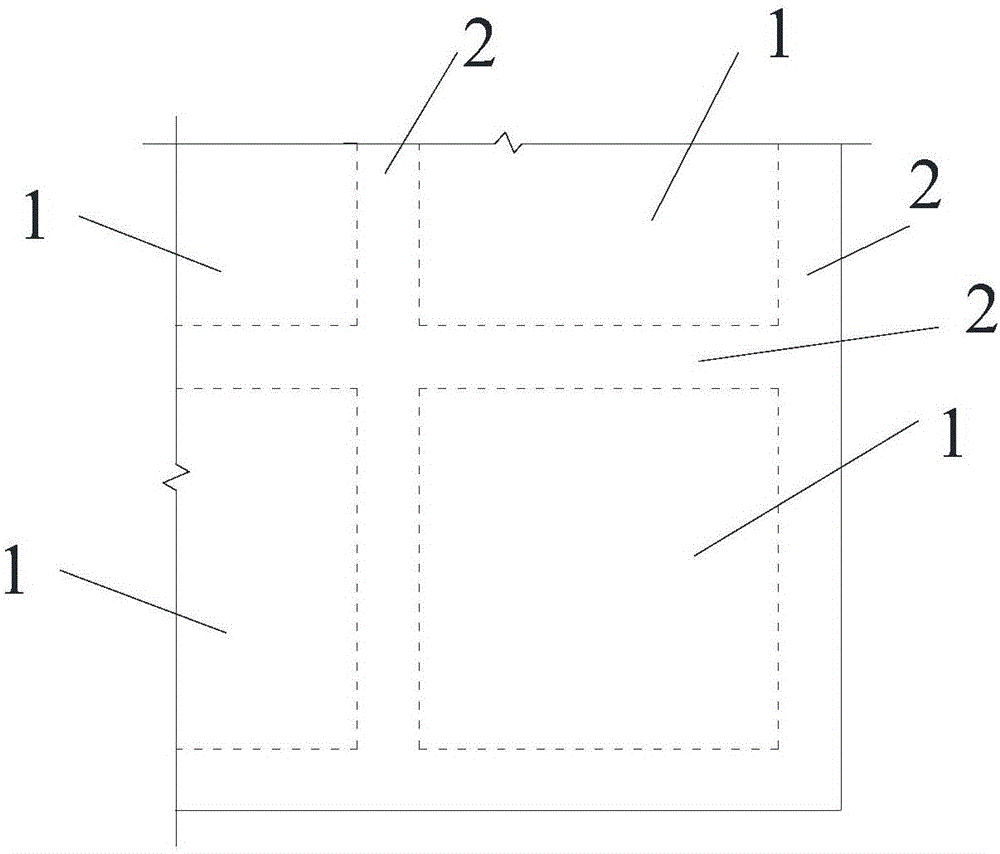

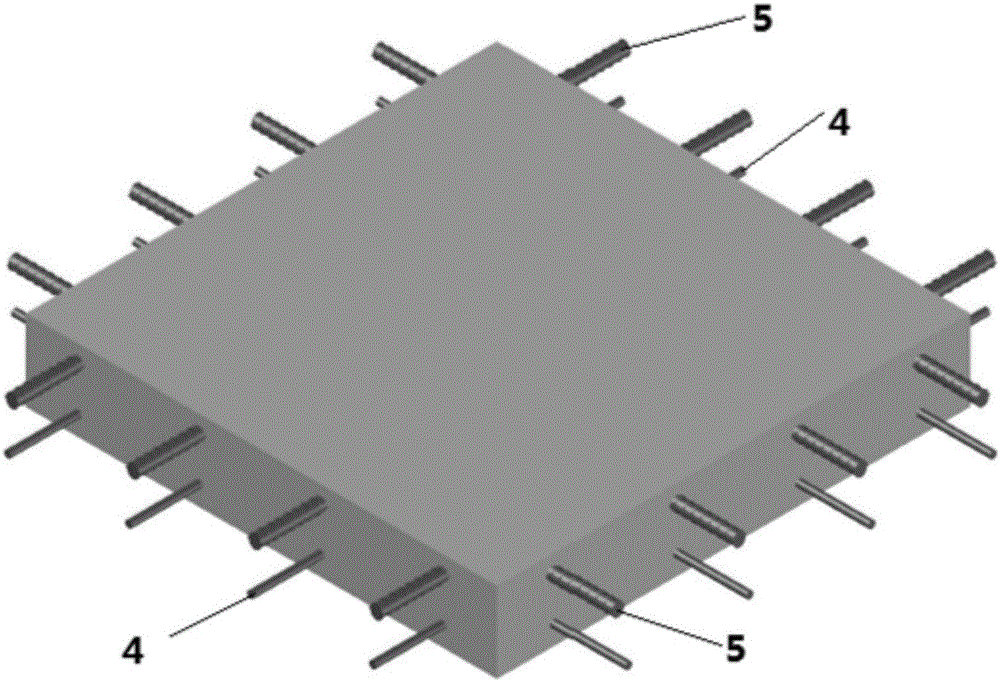

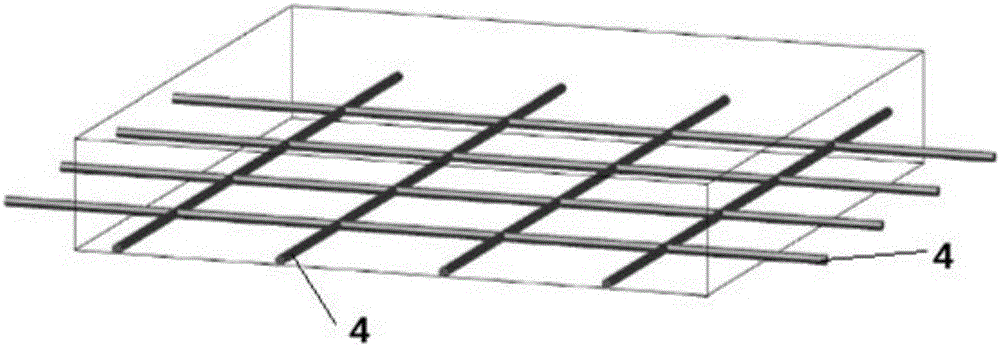

[0044] Embodiment 1 (assembly structure where prefabricated floor slabs are supported at shear walls)

[0045] Such as Figure 8 As shown, it is an assembly structure in which the prefabricated floor is supported at the shear wall, and the assembly objects are the prefabricated floor 1 , the lower shear wall 11 and the upper shear wall 12 . The prefabricated floor 1 is provided with the prestressed steel bar 4 at the bottom of the slab and the common steel bar 5 at the top of the slab, both of which protrude enough from the edge of the slab to ensure the required length of connection or anchorage; The cavity left between is filled by post-cast concrete 9 .

[0046] During assembly and construction, the prefabricated floor 1 must first be transported, hoisted and placed in place and the construction support must be prepared. The bottom surface of the floor is flush with the top surface of the lower shear wall 11, and the top surface of the floor is flush with the bottom surfac...

Embodiment 2

[0047] Embodiment 2 (assembly structure where prefabricated floor slabs are supported on composite beams)

[0048] Such as Figure 9 As shown, it is an assembly structure in which the prefabricated floor slab is supported at the composite beam. The assembly objects are the prefabricated floor 1 and the composite beam 13. The length of the slab edge is sufficient to ensure the connection or anchoring length; the composite beam 13 and the prefabricated floor 1 are connected by post-cast concrete 9 .

[0049] During assembly and construction, the prefabricated floor 1 must first be hoisted in place and the construction support must be prepared. The bottom surface of the floor is flush with the top surface of the prefabricated part of the composite beam 13; Temporary local load 10, the size of the load should be controlled according to its ability to roughly offset the anti-arch deflection caused by the prestressing effect of the prefabricated floor 1 during manufacture; The bot...

Embodiment 3

[0050] Embodiment Three (Assembly structure where prefabricated floor slabs are supported on complete beams)

[0051] Such as Figure 10 As shown, it is an assembly structure in which the prefabricated floor is supported on the complete beam. The assembly objects are the prefabricated floor 1 and the complete beam 14. The prefabricated floor 1 is provided with the prestressed steel bar 4 at the bottom of the slab and the common steel bar 5 at the top of the slab, both of which protrude from the edge of the slab Sufficient length to ensure connection or anchoring length needs; complete beam 14 and prefabricated floor 1 are connected by post-cast concrete 9 .

[0052] When assembling and constructing, the prefabricated floor 1 must be transported, hoisted and placed in place first, and the construction support must be prepared. The bottom surface of the floor is flush with the top surface of the complete beam 14; Local load 10, the size of the load should be controlled accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com