A method for high-gas coal seam working surface drilling and exploitation gas pre-drainage

A technology for working face and gas drainage, which is applied to the field of pre-draining gas in high-gas coal seam drilling and mining, can solve problems such as gas influx, and achieve the effects of reducing engineering volume, saving production costs, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

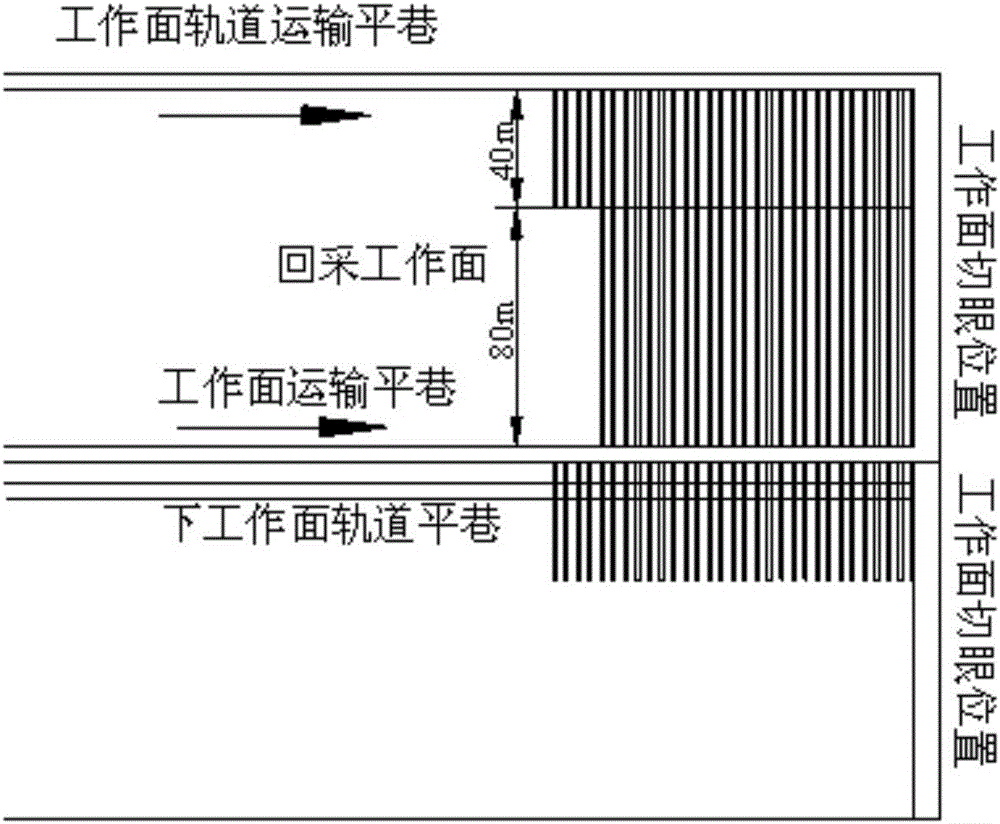

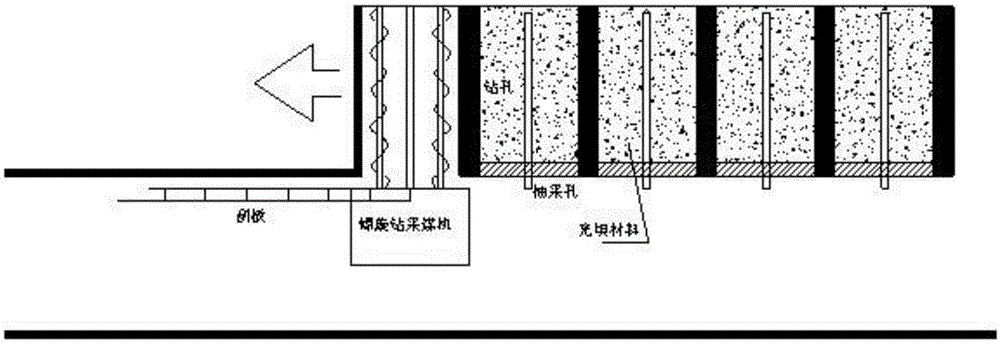

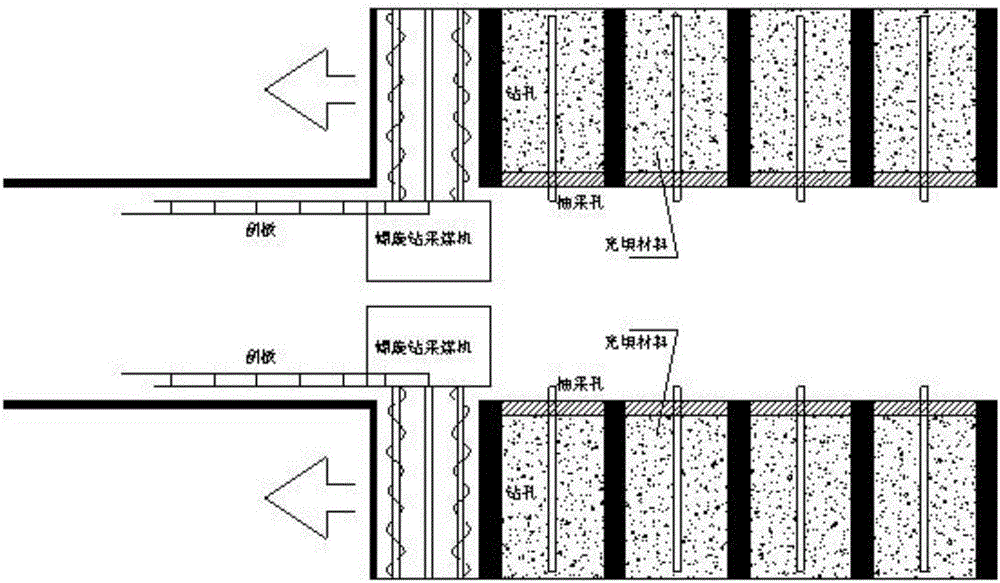

[0061] Example 1: Arrange auger drilling rigs along the trough on the first mining working face. For safe drilling, the inclined length of the first mining working face is generally required to be less than 120m; Drilling rigs are arranged along the trough below the face, on the one hand, to drill 80m to this working face, and on the other hand, to drill not less than 40m to the next working face, and the distance between the drilling holes is 2-3m. figure 1 shown.

[0062] Different from traditional auger drilling for thin coal seams, the present invention is aimed at high-gas coal seams. The auger shearer is used to drill an extremely thin coal seam of about 0.3m on the working face along the trough, in order to form a better quality of drainage The concentric holes are arranged around the auger and filled with high water filling equipment in time.

[0063] Due to the opening of the hole, the stress concentration around the drilling hole is caused. Through the analysis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com