Cable automatic laying design method based on coordinate identification

A design method and automatic laying technology, applied in calculation, instrumentation, data processing applications, etc., can solve problems such as difficulty in ensuring design accuracy, large error range, and poor traceability, so as to improve design efficiency and accuracy, and improve efficiency and accuracy, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

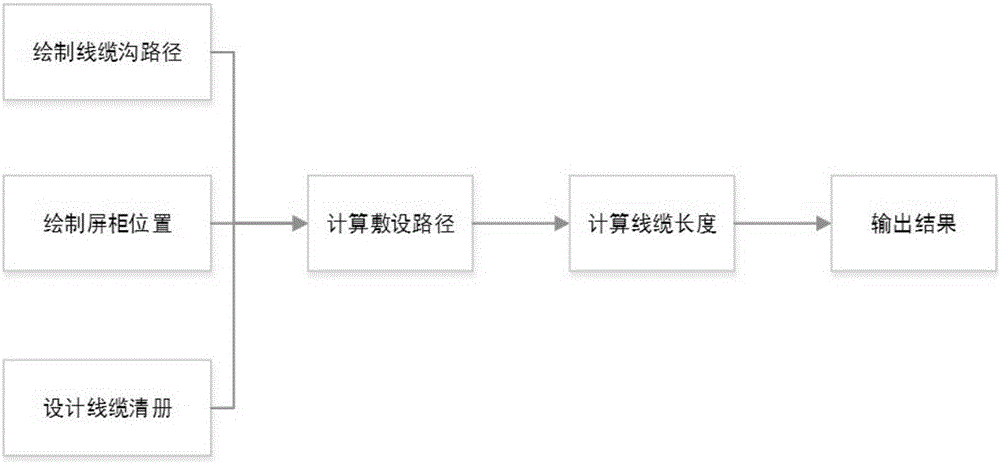

[0025] An automatic cable laying design method based on coordinate recognition, such as figure 1 shown, including the following steps:

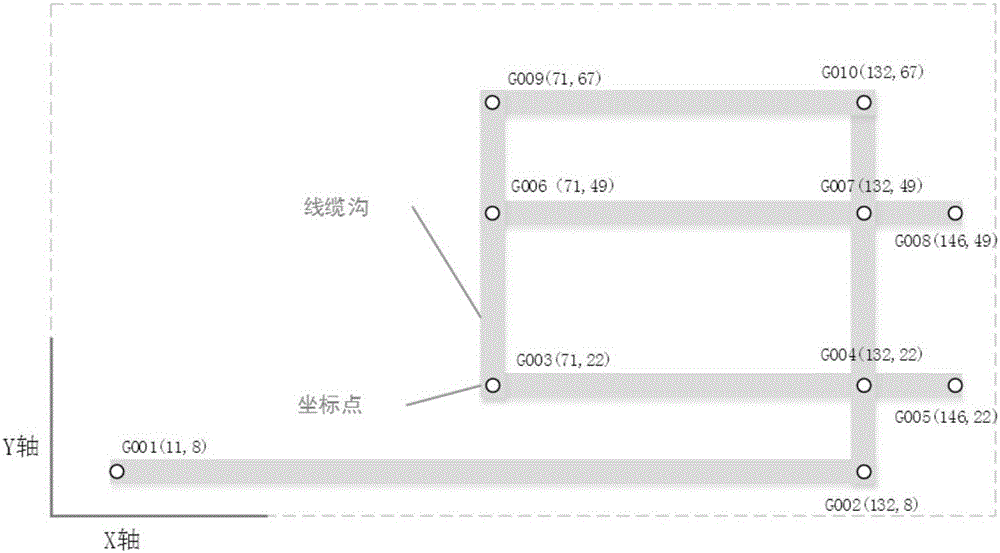

[0026] (1) Collect the path information of the cable trench, and draw the path map of the cable trench according to the set zoom ratio;

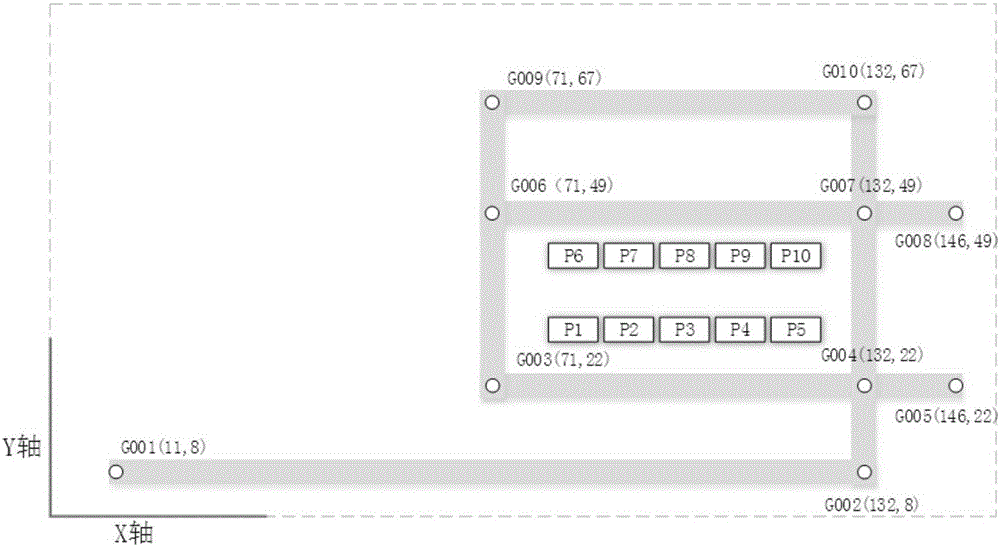

[0027] (2) Collect the position information of the screen cabinets, draw the layout diagram of the screen cabinet positions, and number the screen cabinets in order; superimpose the position layout diagram of the screen cabinets and the path diagram of the cable trench into the same coordinate system;

[0028] (3) Collect the cable information in the substation, form the cable inventory with the information of all cables in the substation, and use it as the input condition for cable laying;

[0029] (4) Determine the projection point of each screen cabinet on the nearest cable ditch in the vertical direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com