Device for treating or machining a surface

A technology for surface processing and surface treatment, which is applied in the field of devices for surface treatment or surface processing, and can solve problems such as large measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

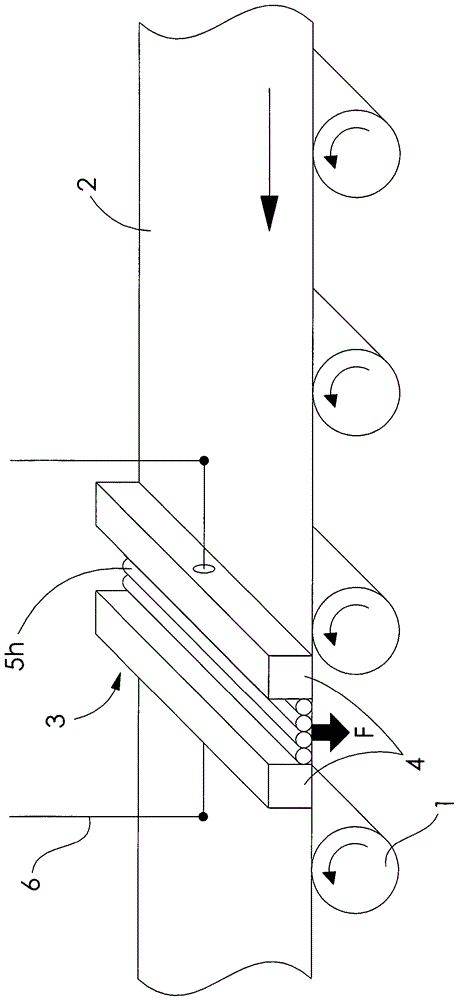

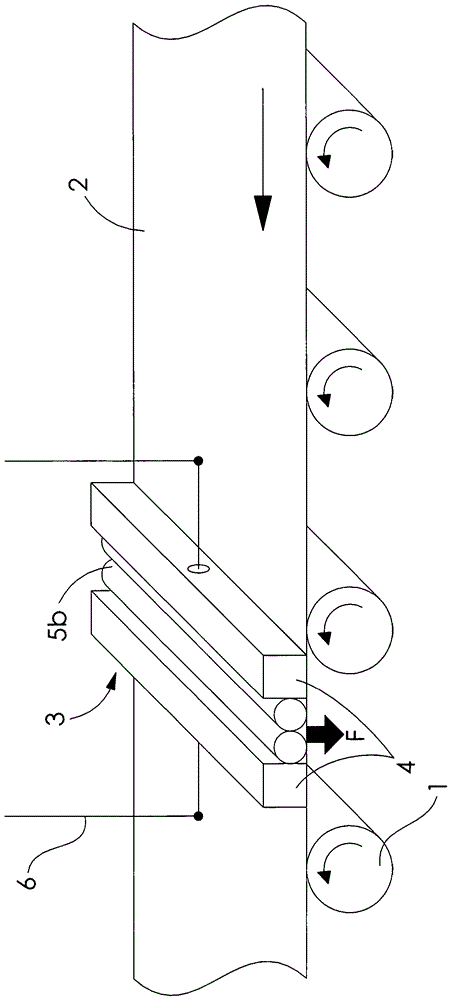

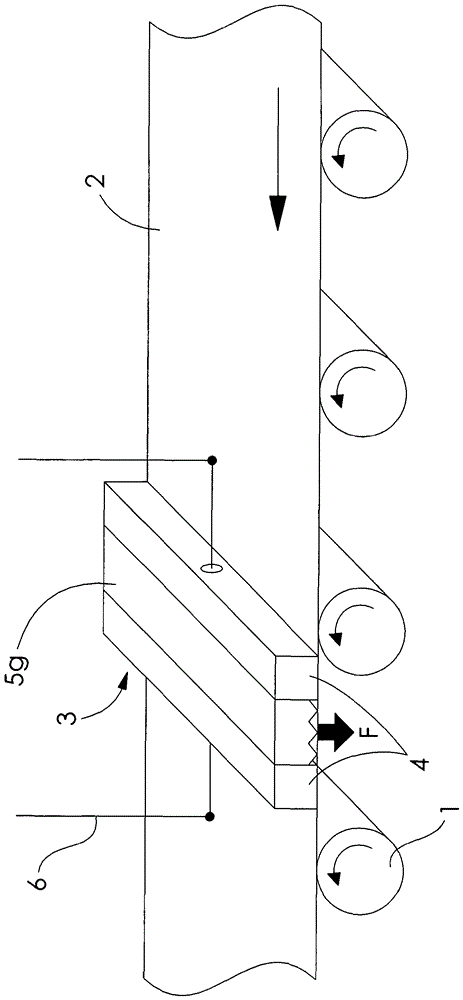

[0034] picture 1 schematically shows Device for spraying oil. The strip material to be sprayed, such as for example sheet metal, passes over driven rollers 1 be guided. in work unit 3 Contains Ultrasonic Oscillator Module 4 and spray nozzles 5a . The ultrasonic oscillation module 4 on its underside and on the surface of the strip material 2 ultrasonic waves - Levitation Field ( Ultraschall-Levitationskraftfeld ). The unit of work 3 hanging on a movable suspension 6 and is pressed onto the strip material based on its own weight, that is to say in this example gravity is applied as the pressing mechanism ( Draengmittel ), but mechanical springs or other equivalently acting mechanisms can also be used. through the ultrasonic - suspend - The force field creates a reaction force such that the working cell 3 suspended over the surface of the strip material at a previously determined distance 2 superior. This distance can be adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com