Device for inspecting workpiece surfaces and strip materials

A technology for inspecting the workpiece surface and inspecting the workpiece. It is applied in the field of devices for inspecting the workpiece surface. It can solve the problems of changing the surface temperature of the strip material, being unable to be used, and damaging the sensitive surface of the strip material, etc., and achieves the effect of accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

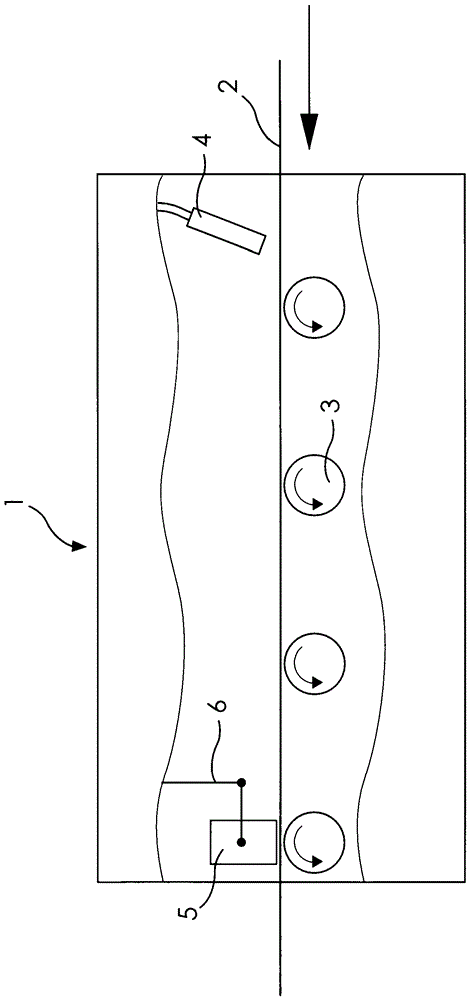

[0015] The device for surface inspection is explained in more detail with an example in conjunction with the two drawings:

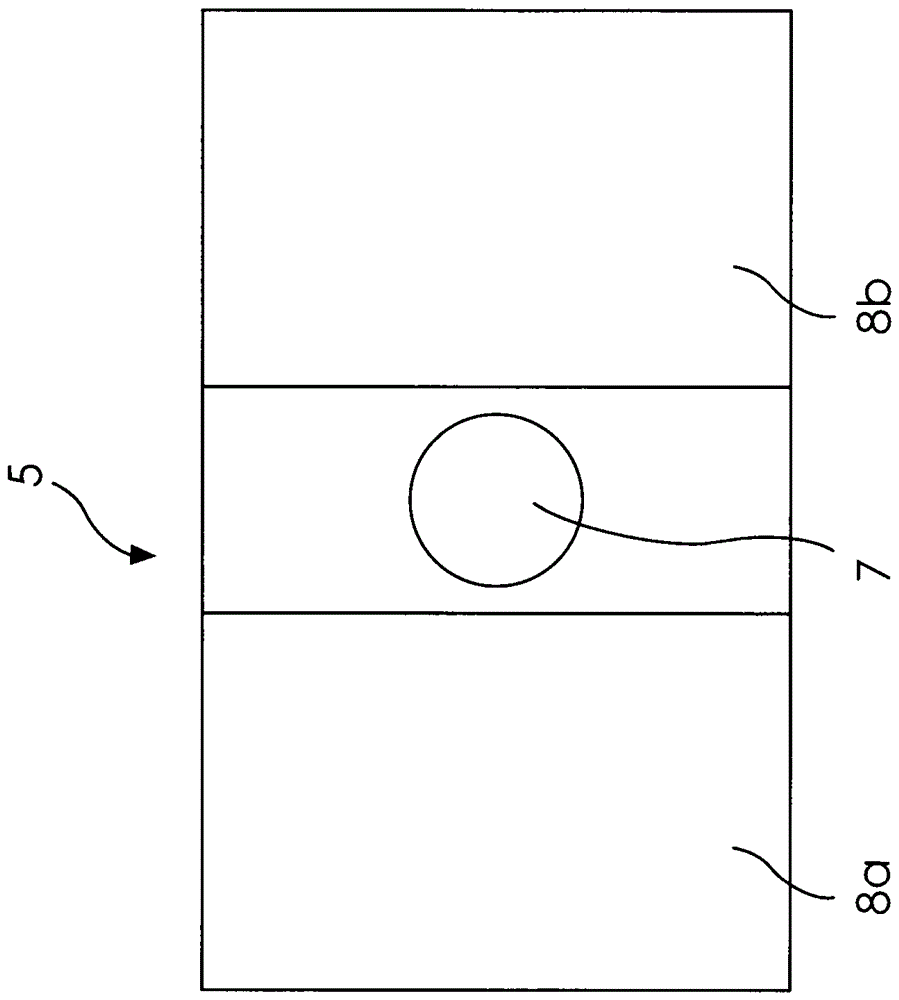

[0016] picture 1 shows the tunnel furnace 1 , in which the heat treatment process is carried out. belt material 2 on driven rollers 3 is guided through the tunnel furnace on 1 . In the tunnel furnace 1 at the inlet, by means of spraying devices 4 spray paint onto the strip material 2 superior. In the tunnel furnace 1 A schematically shown sensor unit for surface inspection is arranged at the outlet of 5 . The sensor unit 5 hanging on a movable suspension 6 at and with 300 mu m The distance overhanging the strip material 2 above. Note that the sensor unit 5 The distance with respect to the surface of the strip material without the aid of the movable suspension 6 adjust. the suspension 6 used only to withstand the sensor unit 5 part of the weight. The remaining part of the weight is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com