Method and system for electric traction farming

A traction type, farmland technology, applied in the field of electric traction type farmland farming methods and systems, can solve the problems of large reserved space for crop row spacing, large material and energy consumption, and reduced land use efficiency, etc., to save manpower and increase land use. Efficiency, the effect of reducing farming costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]Definitions of terms in the present invention:

[0049] 1. "Farming machinery" in this manual refers to the five major categories of agricultural machinery including farming, planting, protection, drainage and irrigation, and harvesting.

[0050] 2. Longitudinal refers to the straight direction in which the tillage machinery advances.

[0051] 3. Horizontal refers to the side direction in which the tillage machinery advances.

[0052] 4. The left and right sides of the tillage machinery are judged according to the forward direction of the tillage machinery.

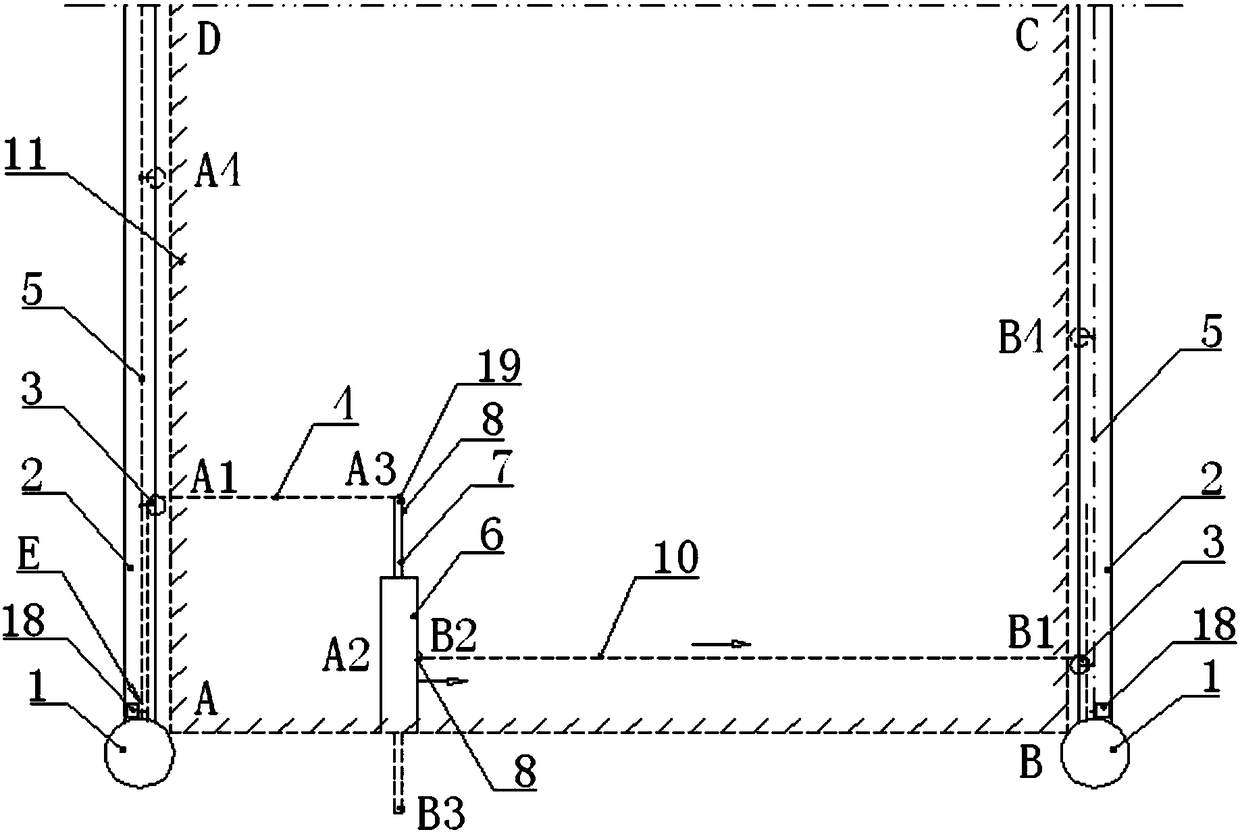

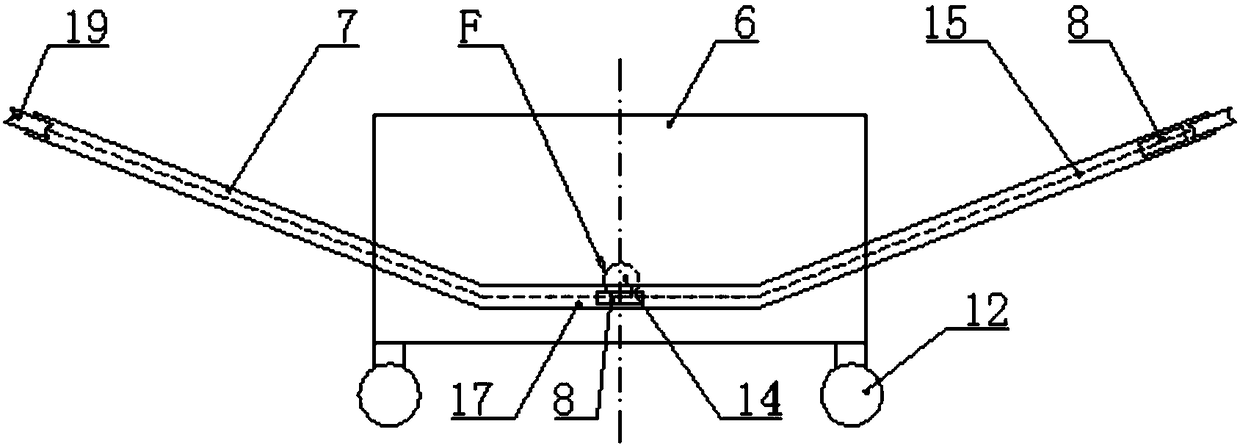

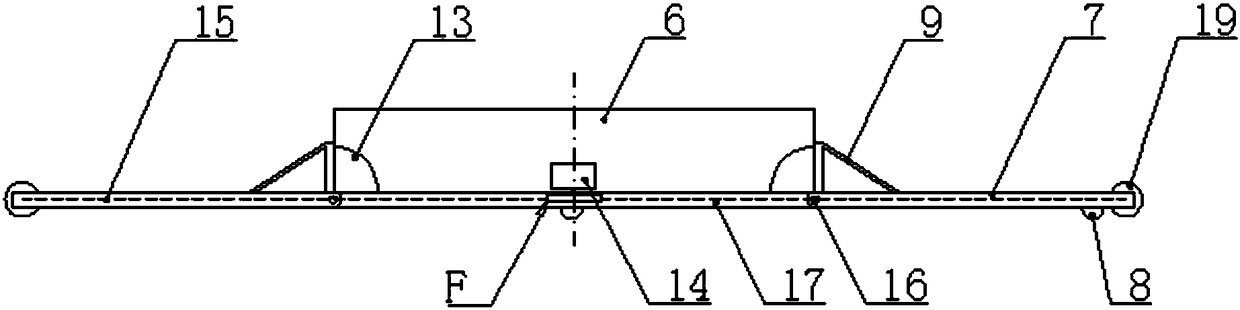

[0053] see Figure 1 to Figure 5 , an electric traction farmland tillage system according to the present invention, comprising a tillage machine 6, an electric winch 1 and a pulley channel 2, a pulley channel 2 parallel to each other is respectively installed at both ends of the farmland 11, two pulley channel One side of the U-shaped constriction of 2 is oppositely arranged, and the traction pulley 3 is slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com