Far Infrared Ray Device for Noodle Drying

A far-infrared and far-infrared technology, which is applied in application, dough processing, baking, etc., can solve the problems of low water transfer rate, low surface vaporization rate, small thermal conductivity, and slow heat transfer speed, so as to shorten the drying time and heat up speed Fast, stable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

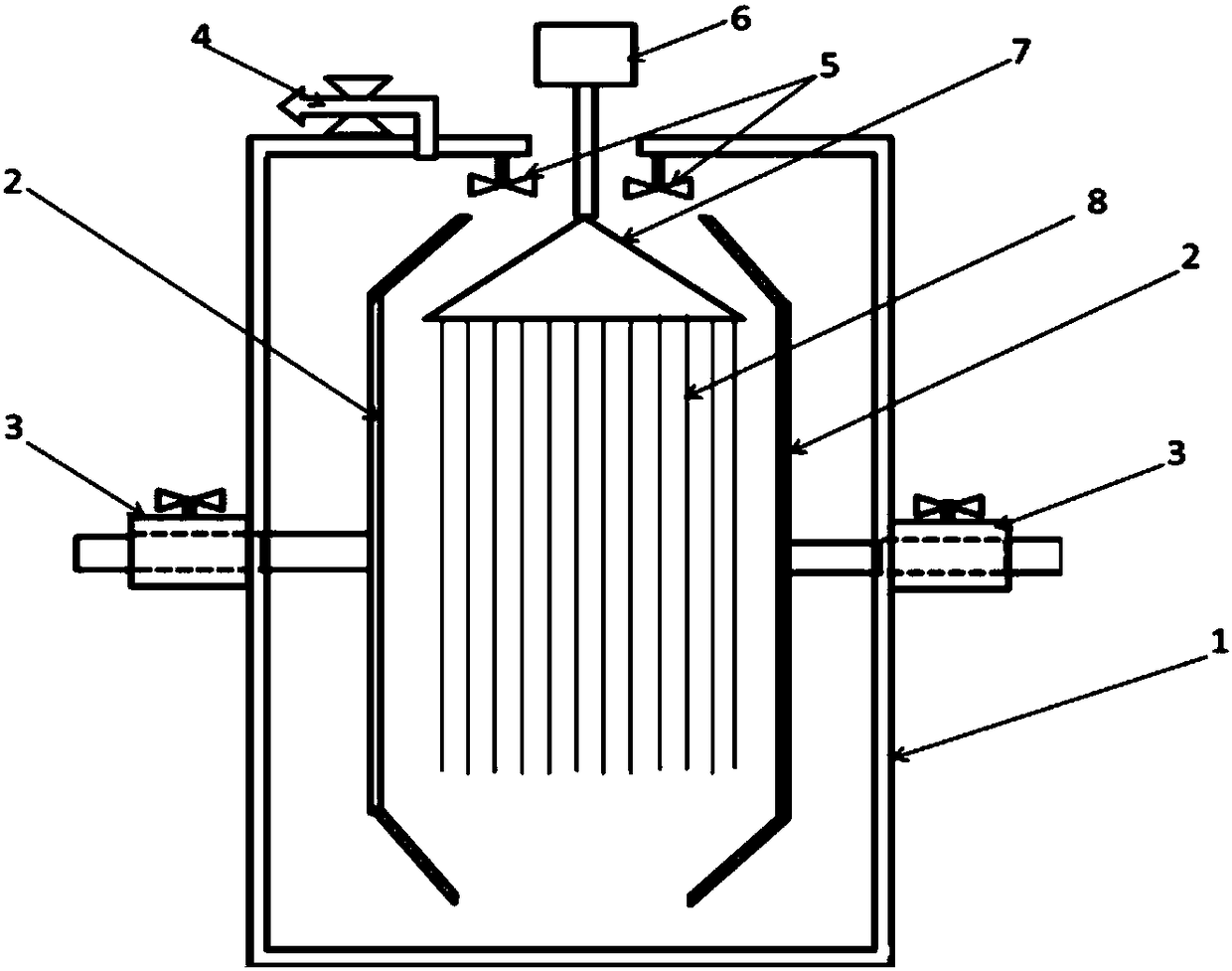

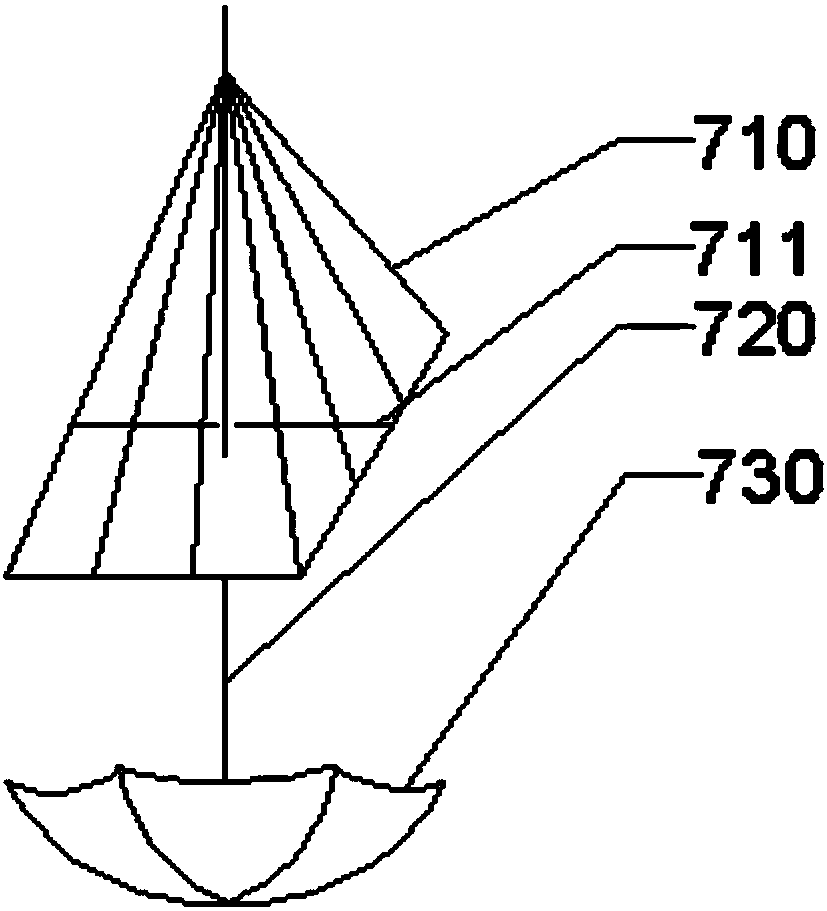

[0042] Such as Figure 1~3 As shown, the far infrared device for drying noodles of the present invention includes:

[0043] Box 1, which is a hollow structure for holding noodles;

[0044] Far infrared device, which includes:

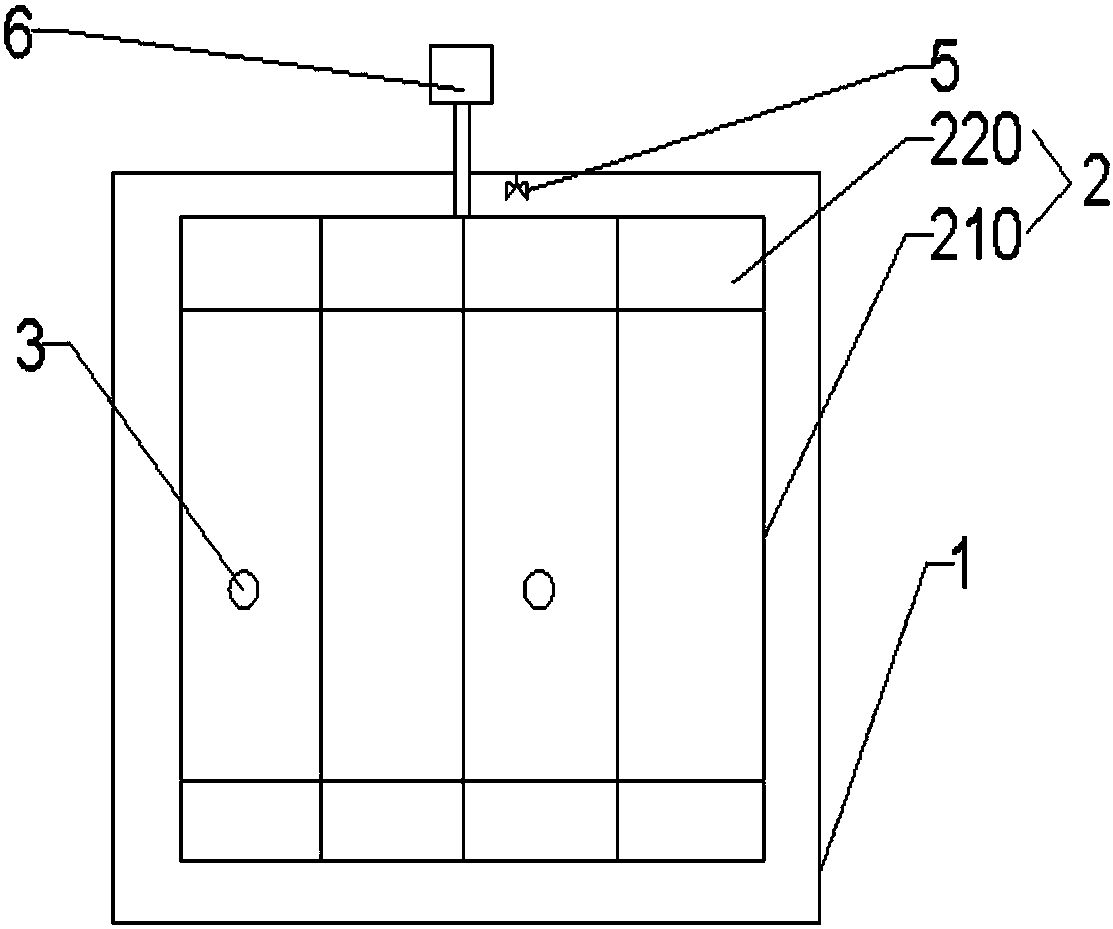

[0045] A pair of far-infrared radiating plates 2 are arranged on both sides of the box body 1, so that the noodles to be dried are located between the pair of far-infrared radiating plates 2, and the far-infrared radiating plates 2 are composed of multiple sets of reflecting plates Combined into a whole, each group of the reflector includes;

[0046] The first reflecting plate 210 is parallel to an inner side surface of the box body 1. The first reflecting plate 210 can be one plate or a plurality of plates spliced together; and

[0047] Two second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com