Electrical dust removal equipment and electrical dust removal system

An electrostatic precipitator and electrostatic precipitator technology, applied in the direction of electrostatic separation, electrode cleaning, external electrostatic separator, etc., can solve the problems of dust removal equipment blockage, spark generation, small filter area, etc., achieve precise control of heating temperature, improve controllability Sexuality and economic benefits are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

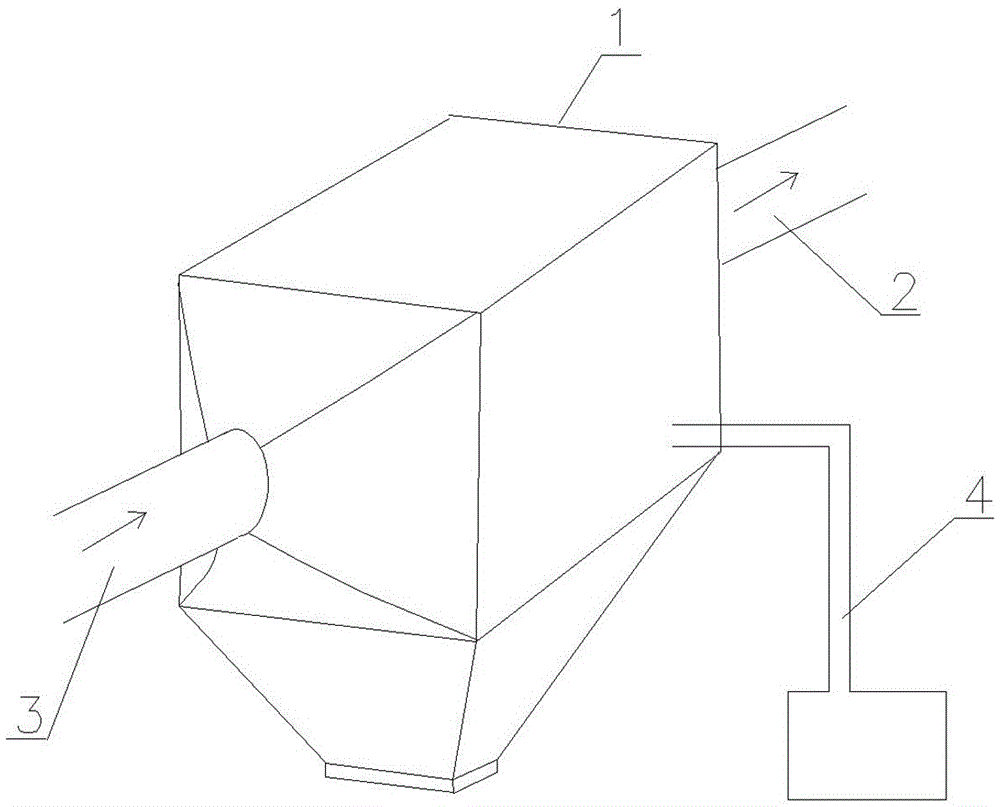

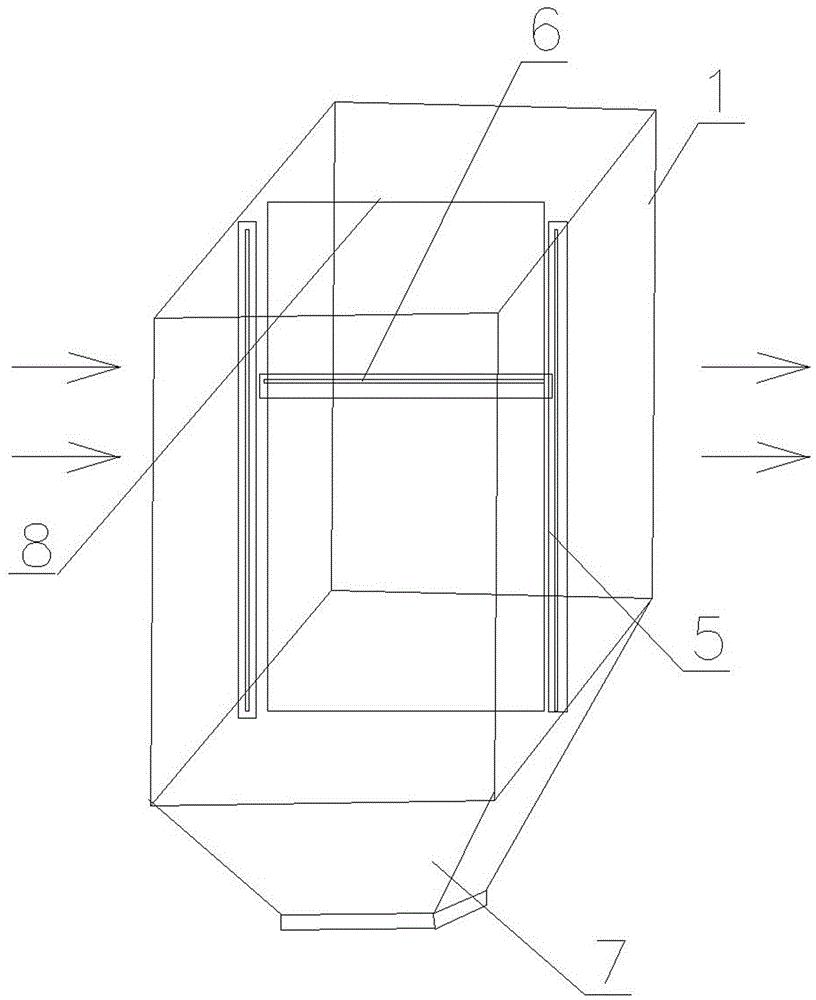

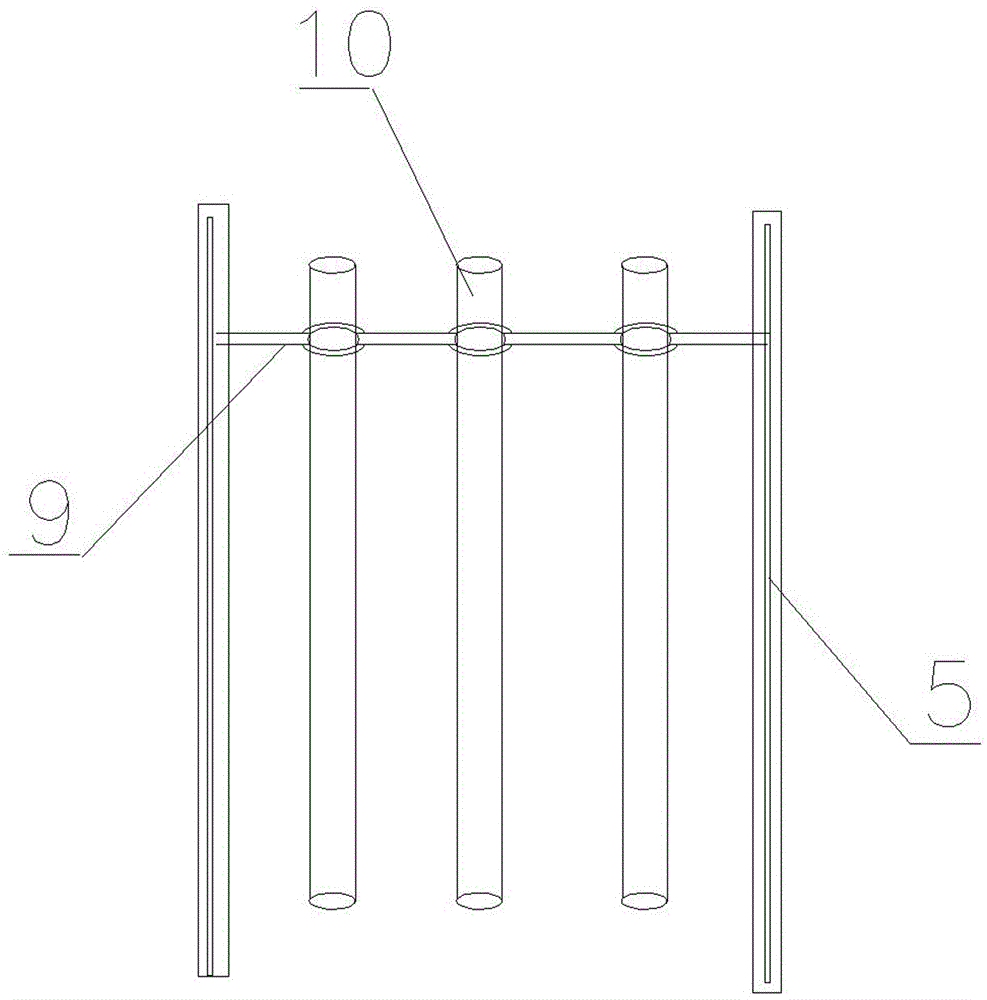

[0037] Such as figure 1 , figure 2 , image 3 Shown: an electric dust removal equipment, including an electric dust removal equipment body 1, the electric dust removal equipment body 1 is connected to an air inlet pipe 3 and an air outlet pipe 2, and the electric dust removal equipment body 1 is provided with a preheating device 4, and the preheating device 4 is a high-temperature gas pipeline, which is connected to the inner cavity of the electrostatic precipitator body 1. The high-temperature gas pipeline can be connected to a high-temperature gas generating mechanism, such as a burner and boiler waste heat. The body of the electrostatic precipitator is provided with a regeneration device, which is a physical regeneration device, and the physical regeneration device includes rails 5 arranged on the two side walls of the dust collecting plate 8 and the inner wall of the electrostatic precipitator body 1 close to each other or connecting parts A scraper 6 that is movably co...

Embodiment 2

[0040] Such as figure 1 Shown: an electric dust removal equipment, including an electric dust removal equipment body 1, the electric dust removal equipment body 1 is connected to an air inlet pipe 3 and an air outlet pipe 2, and the electric dust removal equipment body 1 is provided with a preheating device 4, and the preheating device 4 is a high-temperature gas pipeline, which is connected to the inner cavity of the electrostatic precipitator body 1. The high-temperature gas pipeline can be connected to a high-temperature gas generating mechanism, such as a burner and boiler waste heat. The main body of the electrostatic precipitator is equipped with a regeneration device, the regeneration device is a physical regeneration device, and the physical regeneration device includes a high-temperature gas injection mechanism arranged on the main body of the electrostatic precipitator, which can periodically perform high-pressure on the parts prone to ash as required. Gas blows, and...

Embodiment 3

[0044] Such as Figure 4 Shown: as figure 1 Shown: an electric dust removal equipment, including an electric dust removal equipment body 1, the electric dust removal equipment body 1 is connected to an air inlet pipe 3 and an air outlet pipe 2, and the electric dust removal equipment body 1 is provided with a preheating device 4, and the preheating device 4 is a high-temperature gas pipeline, which is connected to the inner cavity of the electrostatic precipitator body 1. The high-temperature gas pipeline can be connected to a high-temperature gas generating mechanism, such as a burner and boiler waste heat. By preheating the main body 1 of the electrostatic precipitator before the dust removal process starts, and introducing high-temperature gas, according to the flow rate of the high-temperature gas, such as 8-16 m3 / min, it takes 8 to 12 hours to realize the electrostatic precipitator The internal temperature of the equipment body is consistent with the temperature of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com