A spherical cabin and its forming method

A molding method and a technology of a spherical cabin, which can be used in aerospace equipment, simulators of space navigation conditions, instruments, etc., can solve problems such as complex costs, and achieve the effects of economical processing costs, convenient manufacturing, and high crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

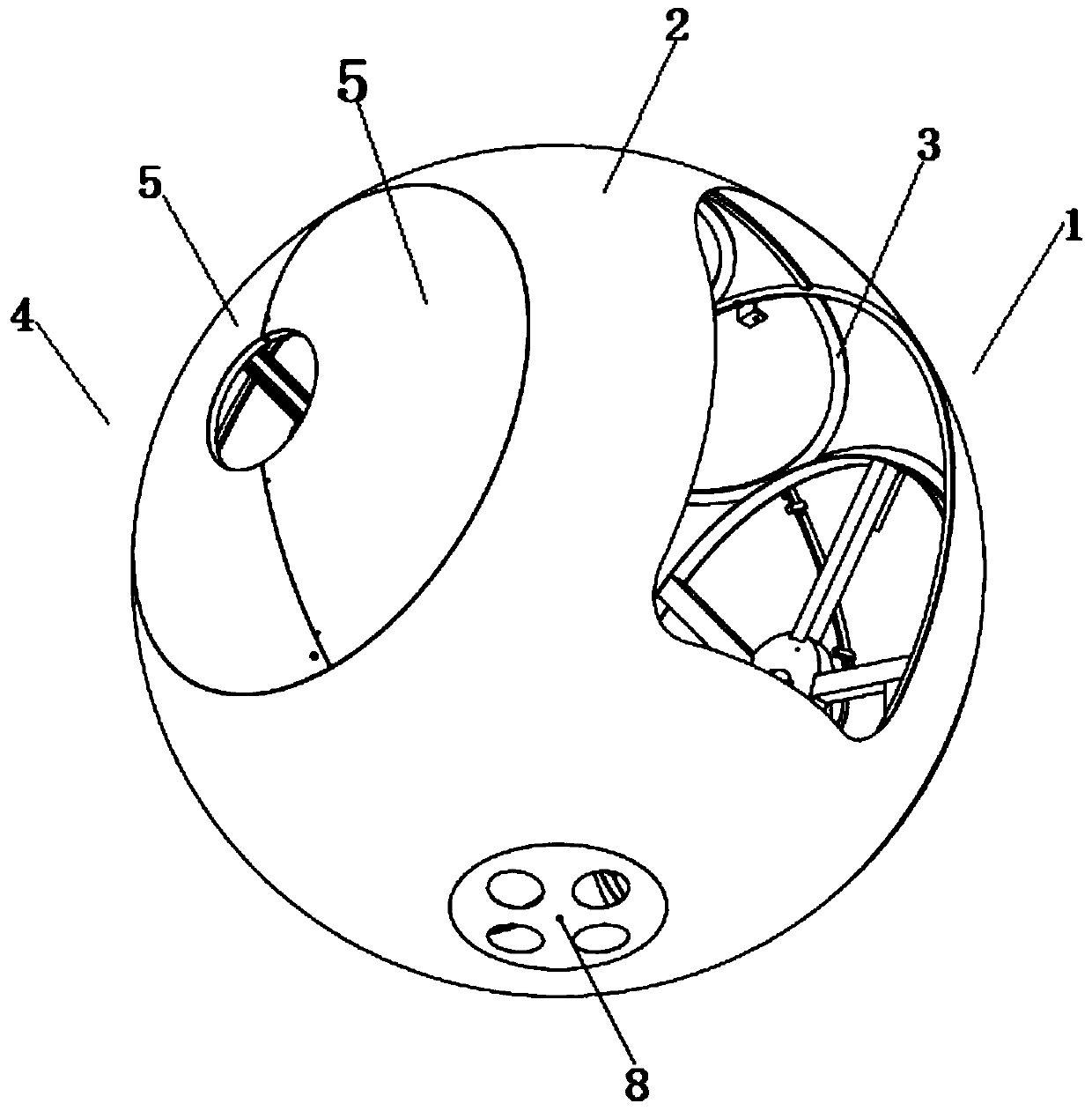

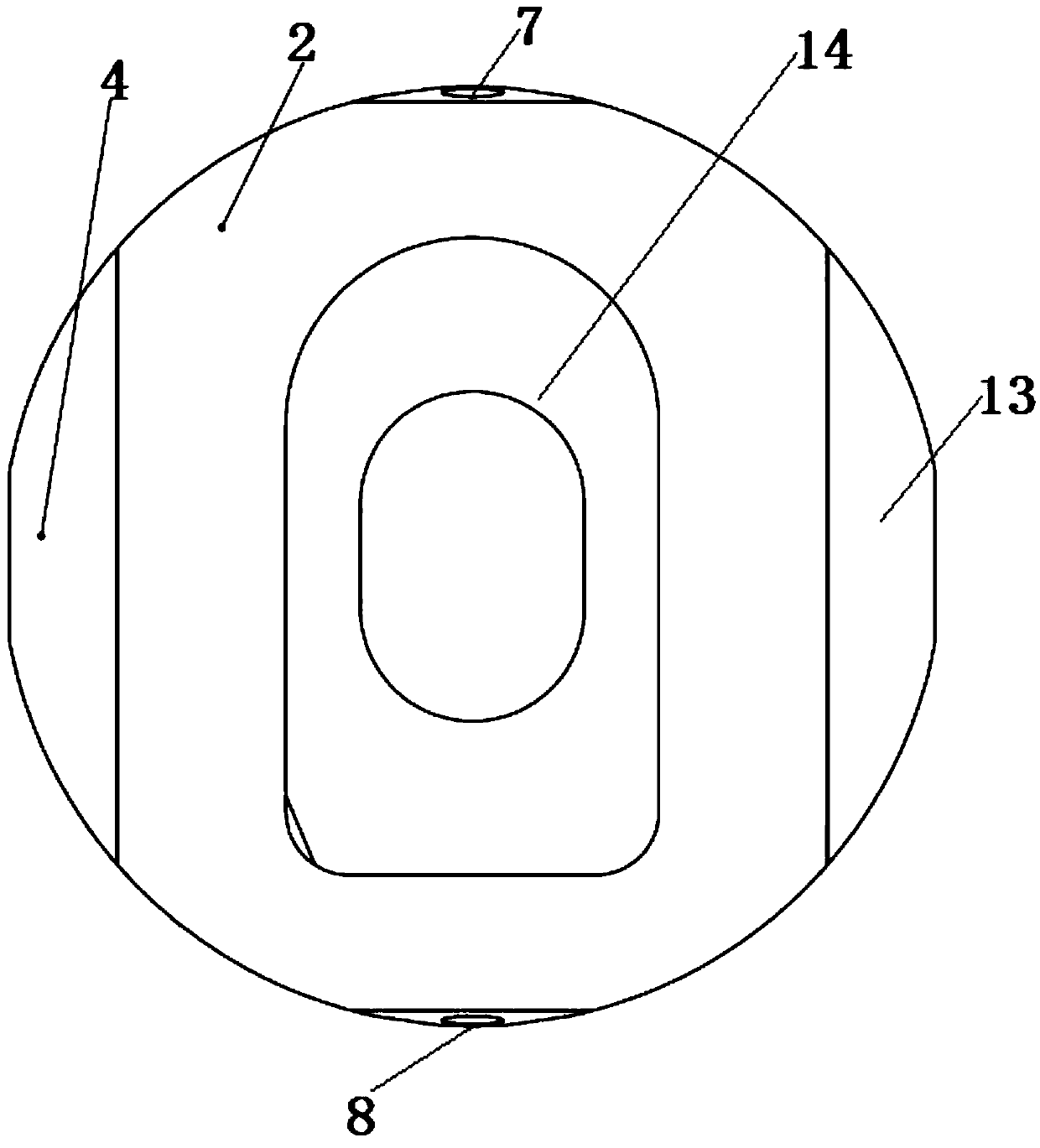

[0022] Embodiment 1: comprising a spherical drum-shaped main body 1, the drum-shaped main body 1 includes a shell 2 and a frame 3, the shell 1 is wrapped on the outer surface of the frame 2, and the left and right sides of the shell 2 are respectively provided with a second A crescent-shaped component group 4 and a second crescent-shaped component group 13, the first crescent-shaped component group 4 and the second crescent-shaped component group 13 are respectively welded on the shell 2, and the front side of the shell 2 is provided with a hatch 14 , the frame 3 is welded by reinforcing ribs 11, angle steels 12, channel steels and spokes 10 in the cabin.

[0023] The first crescent-shaped component group 4 includes two round pot-shaped first crescent components 5 assembled and welded, and the second crescent-shaped component group 13 includes two round pot-shaped second crescent components assembled and welded. A first hub 9 and a second hub 15 are respectively formed on the ...

Embodiment 2

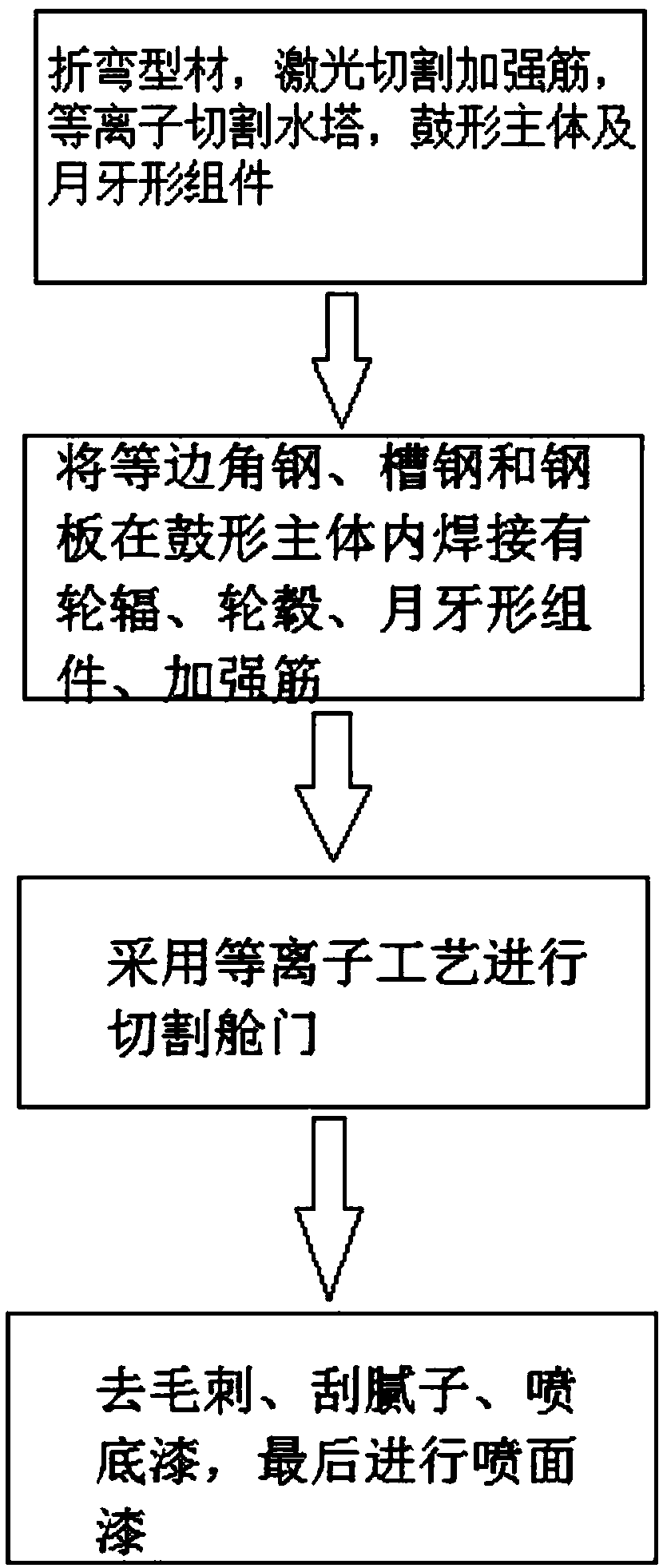

[0029] Embodiment 2: first select some spherical water towers as the main body of the spherical cabin and equilateral angle steel, channel steel and steel plate as auxiliary components, then cut and trim the edges, and equilateral angle steel, channel steel and steel plate are welded in the drum-shaped main body. Spokes, hubs, crescent-shaped components, and stiffeners complete the basic structure of the spherical cabin. Finally, the plasma process is used to cut the hatch; deburring, puttying, primer spraying, and finally spraying topcoat.

[0030] The reinforcing rib of the crescent-shaped component is made of 3mm thick steel plate with a width of 35mm, all of which are formed by laser cutting; the runout of the projected circle in any direction shall not exceed 10mm; the concentricity of the two hubs shall not be less than 2mm, which must be guaranteed by welding tooling), and reinforcing ribs.

[0031] Due to the adoption of the above technical solution, the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com