Dehydration system of washing machine

A washing machine and motor-driven technology, applied in the field of washing machines, can solve problems such as waste of electric energy and machine consumption, waste of time, safety accidents, etc., and achieve the effects of prolonging service life, ensuring safety, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with specific embodiments.

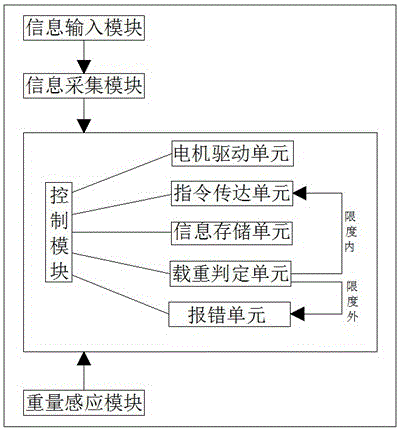

[0017] A washing machine dehydration system proposed by the present invention includes an information input module, an information collection module, a weight sensing module and a control module;

[0018] The information input module is used for the user to set the dehydration time and dehydration speed according to the dehydration needs;

[0019] The information collection module is used to collect the information input by the user and transmit the information to the control module;

[0020] Weight sensing module, used to measure the total weight of dehydration, and transmit the weight information to the control module;

[0021] The control module includes a motor drive unit, an instruction transmission unit, an information storage unit, a load determination unit, and an error reporting unit, and the load determination unit is respectively connected to the error reporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com