A method for arranging main and side reciprocating teeth on insertion holes of a linking guiding and sealing tooth insertion base, and an impacting device with mining machine insertion holes with main and side reciprocating teeth

A technology of guiding and sealing, side reciprocating teeth, which is applied to driving devices, earth-moving drilling, cutting machinery, etc. Ministry and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

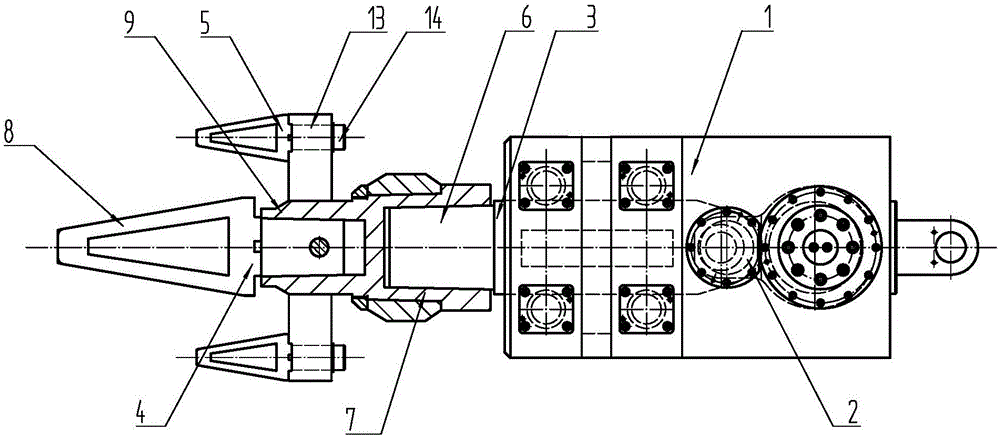

[0384] figure 1 It is the main and side reciprocating tooth impact device for the mining machine socket described in Example 1, including the integrated block seal guide anti-rotation box 1, reciprocating power device 2, interlocking guide seal gear seat 3, main reciprocating teeth 4 and The side reciprocating teeth 5, etc., the end of the interlocking guide seal insertion seat 3 are provided with guide inserts 6, etc., the main reciprocating teeth 4 are provided with side reciprocating teeth 5, etc., and the main reciprocating teeth 4 are provided with main reciprocating teeth sockets 7 etc., the main reciprocating tooth socket 7 etc. are set on the guide post 6, the main reciprocating tooth socket 7 and the guide post 6 are connected through the tapered surface to stop backing, etc., the main reciprocating tooth 4 includes the main punch 8 and The main tooth body 9, etc., connect the main punch tooth 8 and the main tooth body 9 in equal parts, etc., set the side reciprocatin...

Embodiment 2

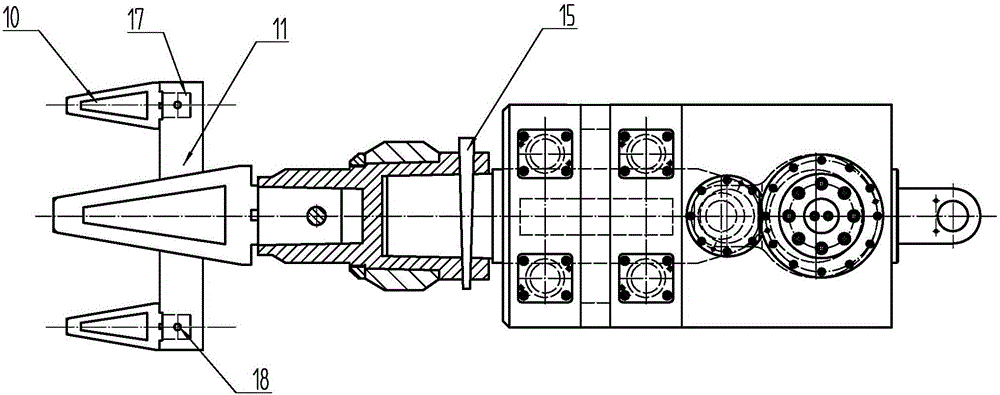

[0402] figure 2 It is the main and side reciprocating tooth impact device for the jack of the mining machine described in Example 2, including the integrated block seal guide anti-rotation box 1, the reciprocating power device 2, the interlocking guide seal gear seat 3, the main reciprocating tooth 4 and The side reciprocating teeth 5, etc., the end of the interlocking guide seal insertion seat 3 are provided with guide inserts 6, etc., the main reciprocating teeth 4 are provided with side reciprocating teeth 5, etc., and the main reciprocating teeth 4 are provided with main reciprocating teeth sockets 7, etc., the main reciprocating tooth socket 7 is set on the guide post 6, the main reciprocating tooth 4 includes the main tooth backstop 16, etc., the main tooth backstop 16 is a tapered head backstop, etc., the main tooth backstop The back piece 16 is connected separately with the main reciprocating tooth 4, etc., and the main tooth backstop 16 is used to connect the main re...

Embodiment 3

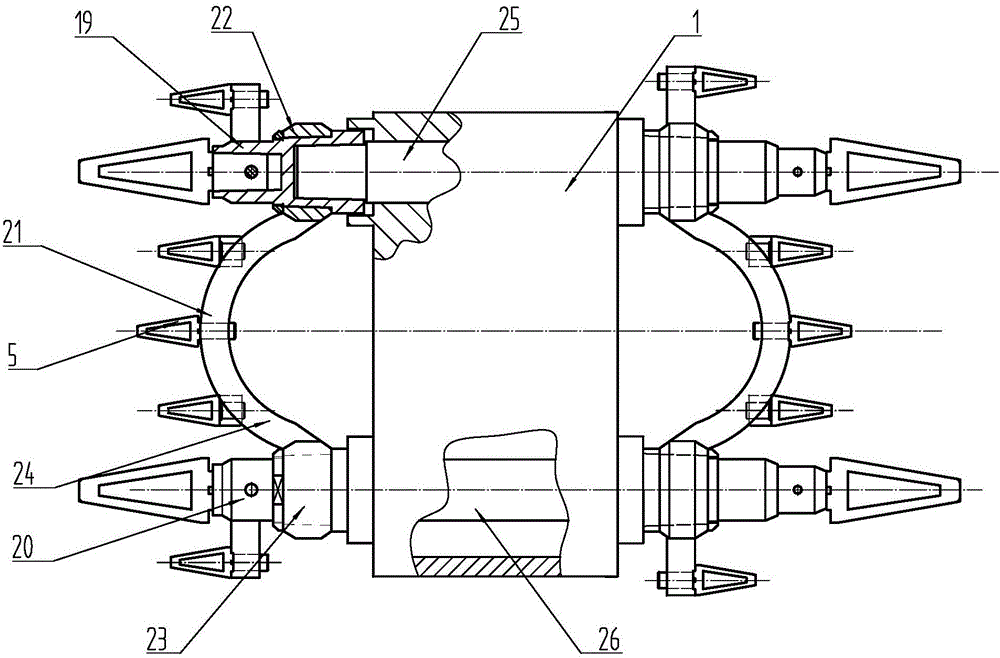

[0406] image 3 , Figure 4 It is the main and side reciprocating tooth impact device for the jack of the mining machine described in Embodiment 3. The main tooth body 9 includes an upper main tooth body 19 and a lower main tooth body 20, and the main reciprocating tooth body 4 also includes a beam sleeve punch rack 21 , the beam sleeve punching rack 21 includes an upper main tooth connecting sleeve 22, a lower main tooth connecting sleeve 23 and a main tooth connecting beam 24, the upper main tooth body 19 is separately connected with the upper main tooth connecting sleeve 22, and the lower main tooth body is connected separately. The tooth body 20 is separately connected with the lower main tooth body connecting sleeve 23. One end of the main tooth body connecting beam 24 is arranged on the upper main tooth body connecting sleeve 22, and the other end is arranged on the lower main tooth body connecting sleeve 23. The main tooth body connecting beam 24 Connect and fix the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com