Application of WSS construction method in shield end reinforcement of water-rich sand layer

A technology of water-rich sand layer and construction method, applied in the field of shield tunneling, can solve the problems of difficulty in controlling the verticality deviation of the pile driver, incompatibility with the upper soft and lower hard strata, and poor water stop control between the piles, so as to reduce the amount of ballast outside the soil. The effect of transportation volume, small reinforcement range and large reinforcement depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

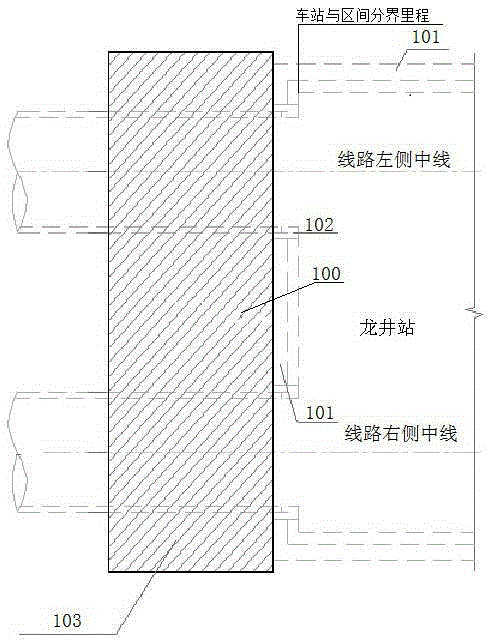

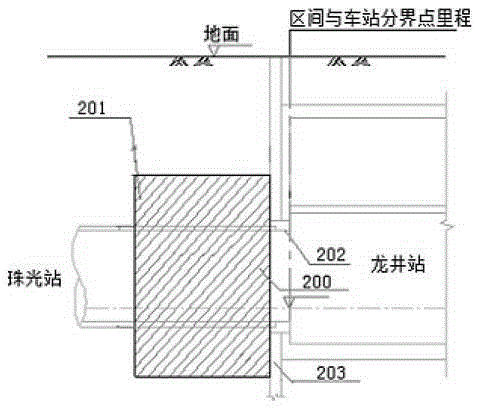

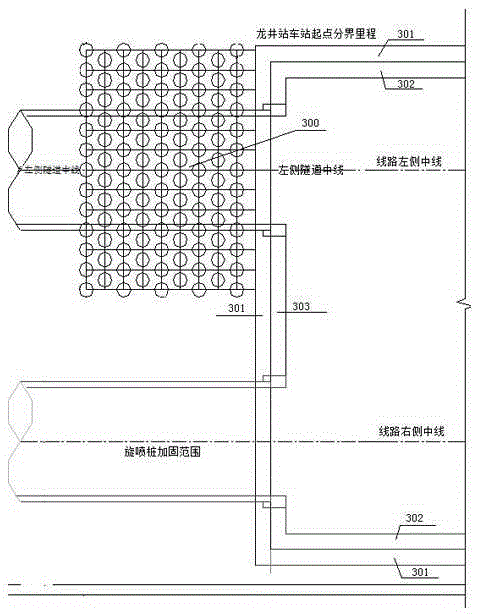

[0030] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0031] An application of WSS construction method (non-shrinkage double liquid grouting improved soil construction method) in the end reinforcement of shield tunneling in water-rich sand layer is provided.

[0032] The WSS construction method grouting process adopts the tunnel drilling rig for deep hole grouting reinforcement, and first uses the solution type grout composed of liquid A and liquid B to drain the soil; when the whole reinforcement is made of liquid A and liquid B After the solution-type grout retreating grouting construction is completed, the soil is consolidated with the suspension-type grout composed of A liquid and C liquid forward grouting.

[0033] The A liquid is water glass, the B liquid is phosphoric acid, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com