Multi-stage backheating hot pressing type vacuum pumping system provided with low-pressure heater and shaft seal heater and adjustment method of vacuum pumping system

A technology of vacuum pumping system and low-pressure heater, applied in lighting and heating equipment, steam/steam condensers, etc., can solve the problems of heavy maintenance workload, easy cavitation of pump body, high investment cost, and save equipment space. Area, saving initial investment, strong suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

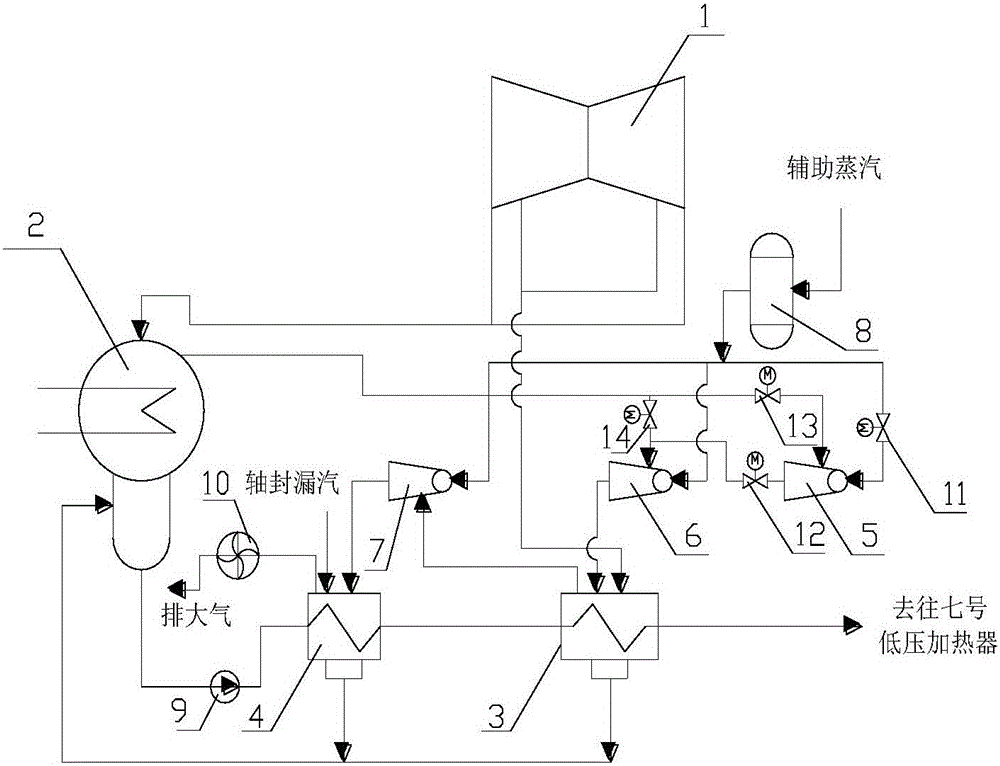

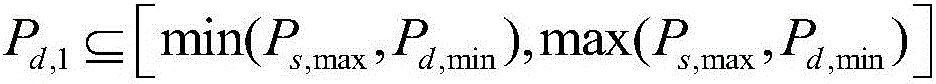

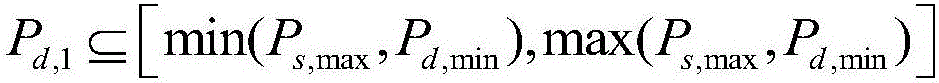

[0047] Taking a 330MW wet-cooling unit in a power plant as an example, the operating pressure of the No. 8 low-pressure heater of the unit is 30KPa at the maximum and 12KPa at the minimum, the shaft seal heater has a slight negative pressure (gauge pressure -2~-6KPa), and the design operating pressure of the condenser is 4.9KPa In summer, due to the increase of circulating water temperature, the maximum back pressure of the condenser can reach 11KPa, so the type selection of the hot press can be carried out based on this constraint. The outlet pressure of the first stage hot press can be maintained at 10-15KPa, and the second The outlet pressure of the first-stage hot press can be maintained at about 30-35KPa, and the outlet of the third-stage hot press can maintain a slight negative pressure to ensure a certain degree of vacuum in the shaft seal cooler and avoid overflow of shaft seal leakage. When the back pressure of the condenser is lower than 11KPa, the three-stage hot pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com