Distributed optical fiber-based transformer winding stress monitoring system

A technology of transformer winding and distributed optical fiber, which is applied in the direction of measurement, instrument, and measurement force by measuring the change of optical properties of materials when they are stressed, and can solve problems such as inability to demodulate signals, gaps, and calculation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

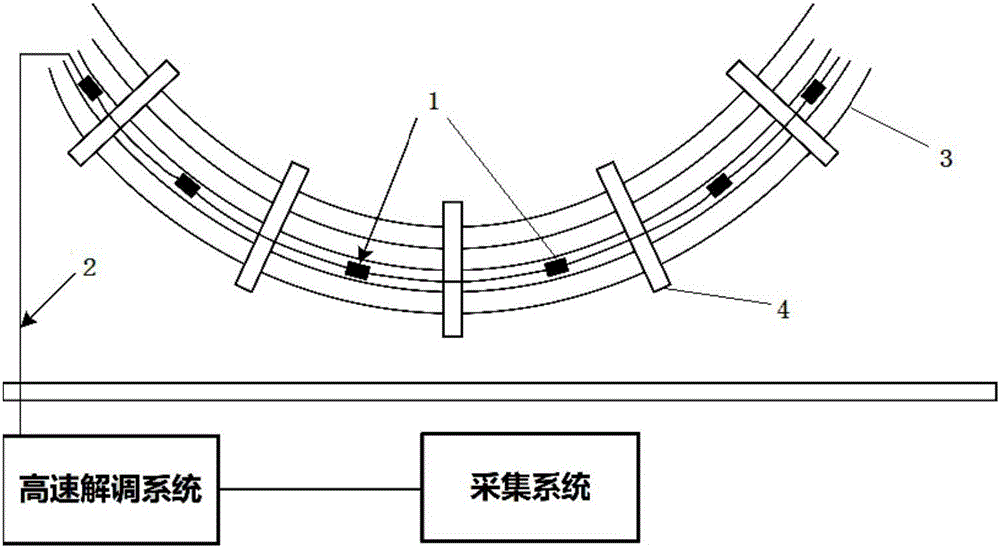

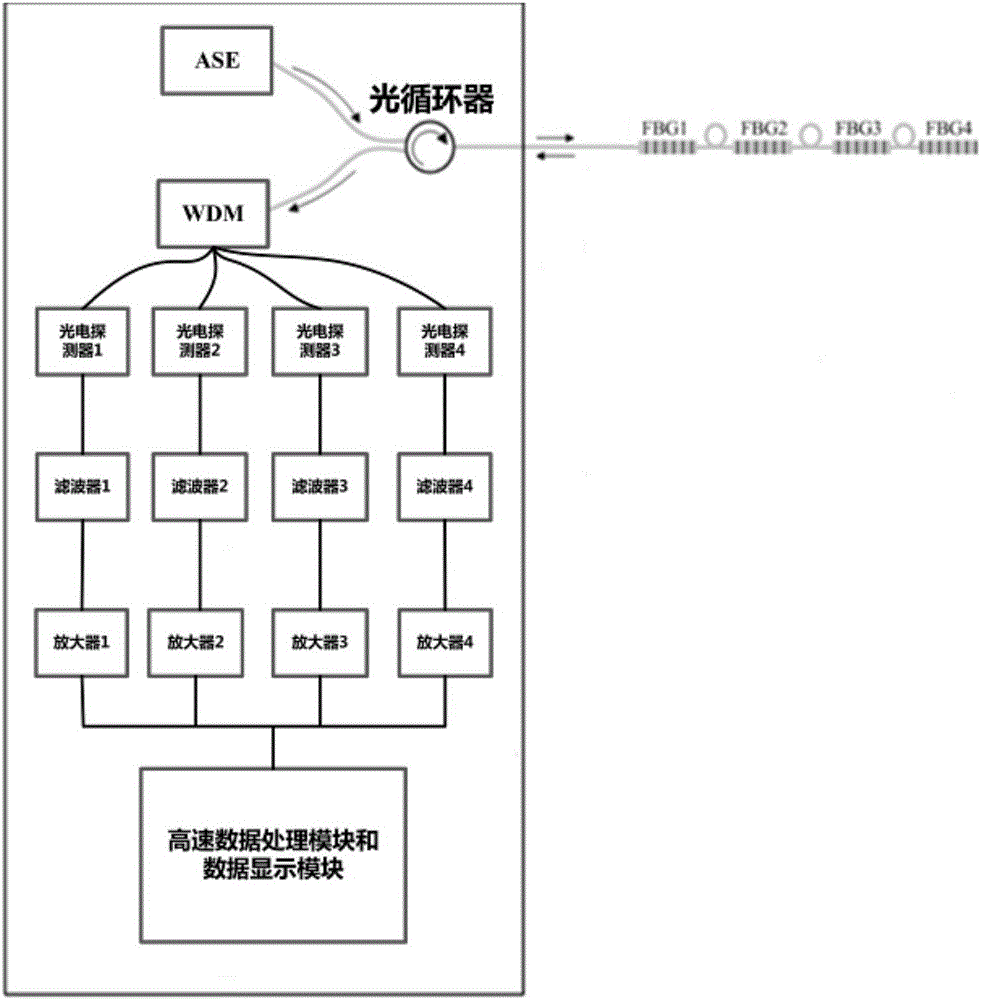

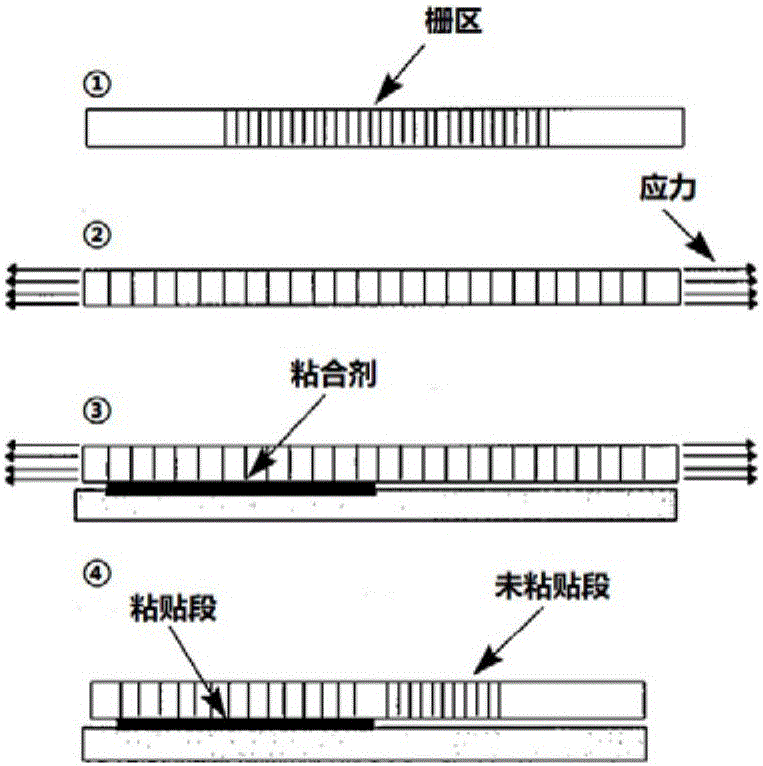

[0017] figure 1 A connection schematic diagram of a transformer winding stress monitoring system based on distributed optical fibers is shown. The optical fiber is packaged by partial pasting, and the fully distributed optical fiber stress sensor is pre-embedded in the winding magnet wire, and then the optical fiber is led out of the sensor and connected to the designed high-speed demodulation system, and the transformer winding stress is monitored in real time through the stress acquisition system. After the winding is affected by the impact force, the fully distributed optical fiber stress sensor embedded in the winding magnet wire is stressed, and the optical signals of different sensors are separated by the wavelength division multiplexing equipment in the high-speed demodulation system, and then the optical signal The conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com