Shale base block dynamic damage evaluation device and method based on liquid pressure pulse

A technology of liquid pressure and evaluation device, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

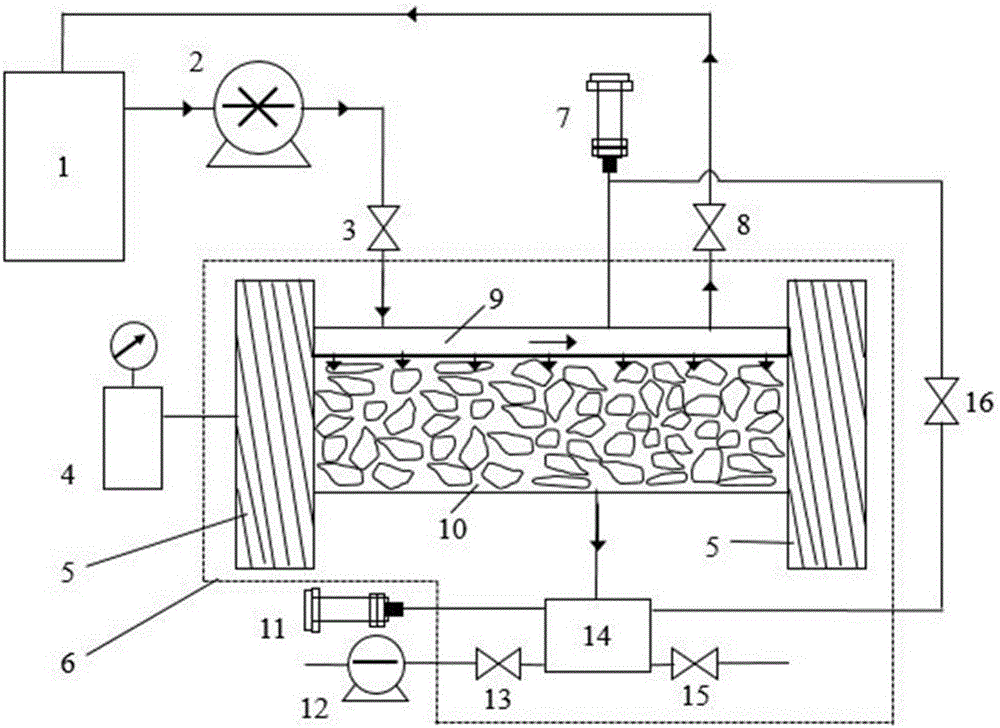

[0042] Such as figure 1 As shown, this embodiment discloses a dynamic damage evaluation device for shale foundation blocks based on liquid pressure pulses, which is used to evaluate the hydraulic permeability of 10 -6 ~10 -2 The dynamic damage degree of the working fluid of tight cores such as shale base blocks in mD mainly includes the upstream standard chamber 9, the downstream standard chamber 14, the core holder 5, the confining pressure pump 4, the vacuum pump 12, the constant pressure and constant flow pump 2, the intermediate Container 1, pressure sensors 7 and 11, thermostatic system 6. Wherein the inlet end of the core holder 5 is connected with the upstream standard chamber 9, and the outlet end is connected with the downstream standard chamber 14; an upstream standard chamber inlet control valve 3 is arranged between the upstream standard chamber 9 and the constant pressure constant flow pump 2, and the middle An upstream standard chamber outlet control valve 8 is...

Embodiment 2

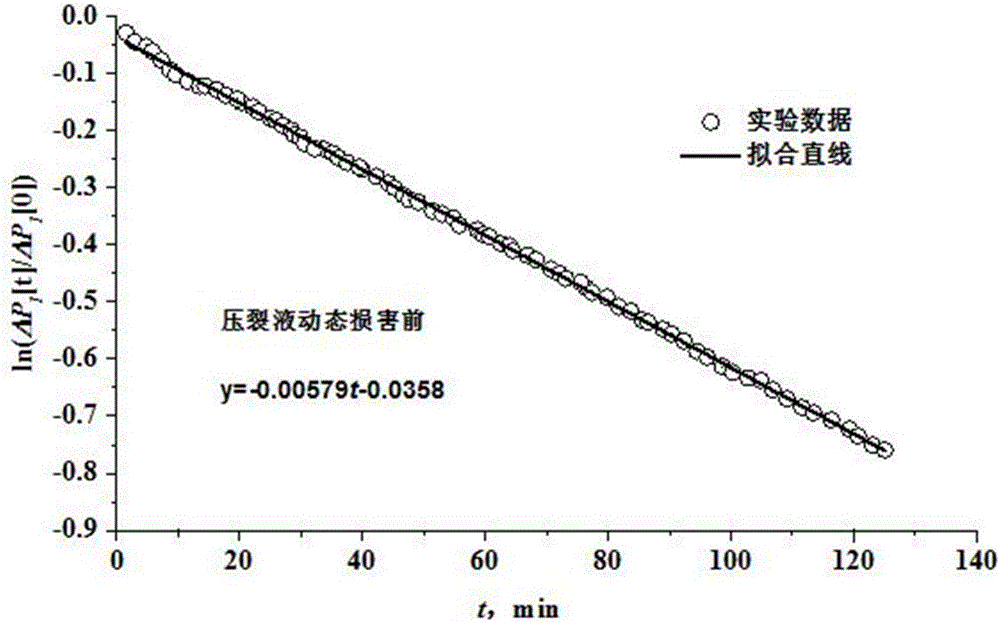

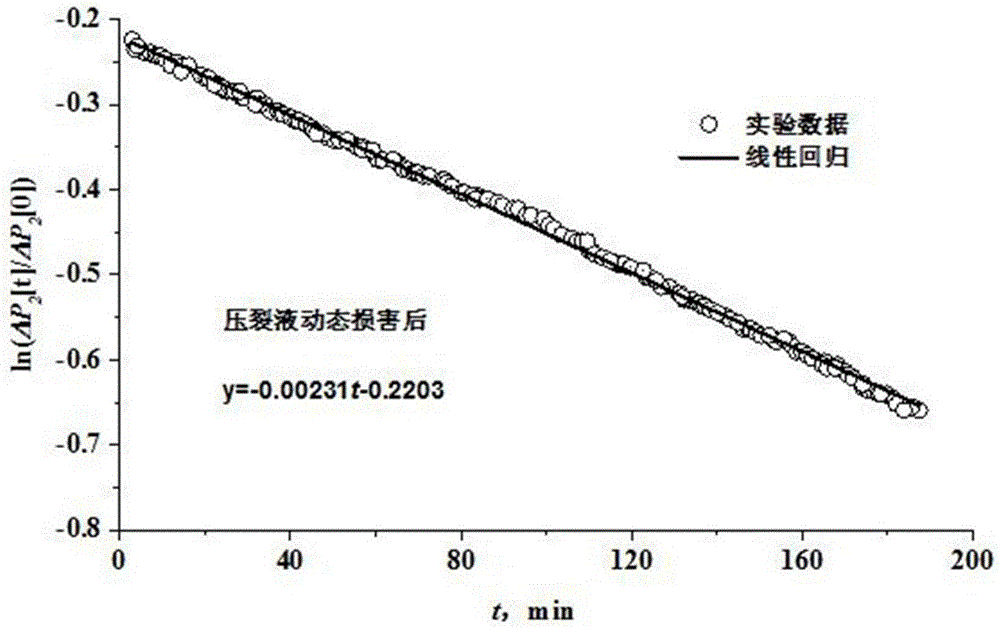

[0049] This embodiment is based on the dynamic damage evaluation method of the shale foundation block based on the liquid pressure pulse. The above-mentioned device is used to evaluate the evaluation method of the dynamic damage degree of the working fluid to the shale foundation block. This method is used to evaluate the hydraulic permeability of 10 -6 ~10 -2 The working fluid dynamic damage degree of tight rock cores such as the shale base block of mD, the rock sample of the embodiment is the shale base block core L-1 of the Longmaxi Formation in the Sichuan Basin (micro-cracks are invisible to the naked eye), and the specific steps are as follows:

[0050] Step 1. Drill the core L-1 of the shale base block of the Longmaxi Formation. The measured diameter is 38.1mm and the thickness is 10.2mm, and it is dried at 80°C for 48 hours;

[0051] Step 2, put a steel rock core (permeability zero) with a diameter of 38.0mm and a thickness of 10.0mm into the core holder 5, and feed he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com