Intelligent diagnosis device and method for transformer winding material

A transformer winding and intelligent diagnosis technology, applied in the field of transformer detection, can solve problems such as difficult operation, hidden safety hazards, high cost, etc., and achieve the effect of simple operation, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

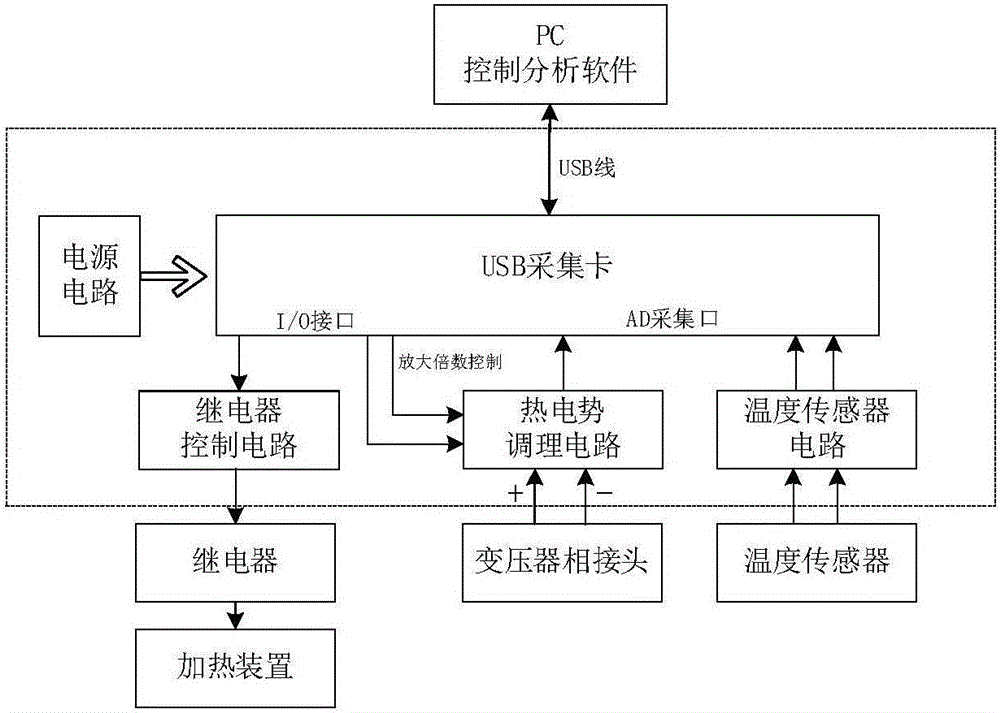

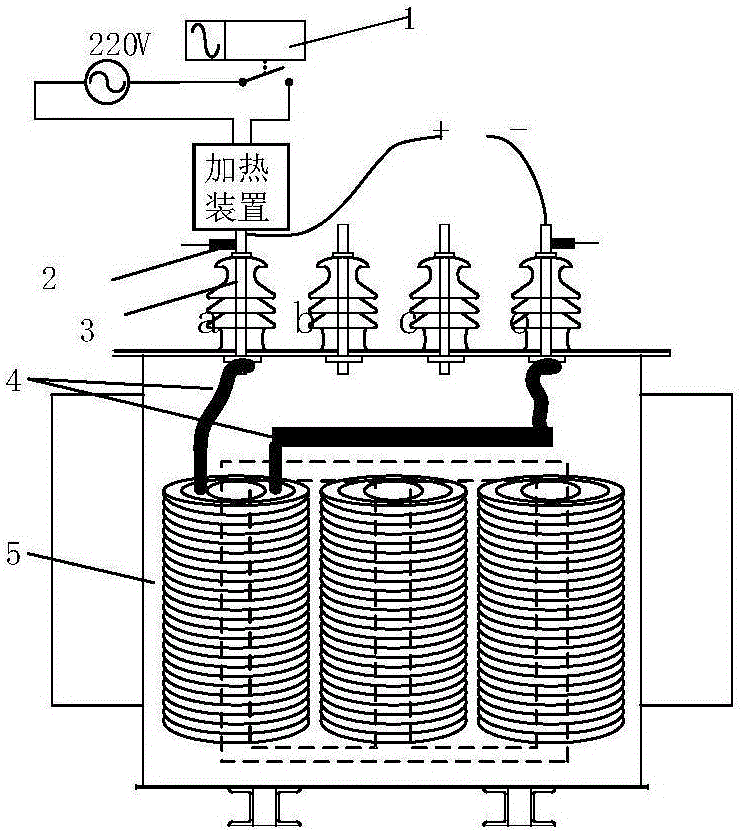

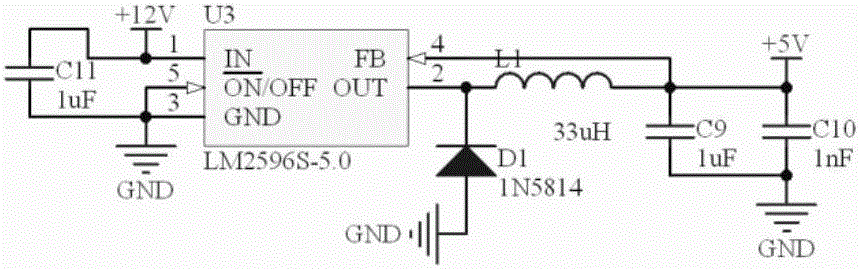

[0047] Such as figure 1 As shown, a transformer winding material intelligent diagnosis device provided in this embodiment includes a PTC heating device, a temperature sensor, an acquisition device and a processor;

[0048] The PTC heating device is connected to the acquisition device through a relay; the PTC heating device is used to heat the beginning of the transformer phase joint conductive rod; the temperature sensor is used to collect the temperature at the beginning of the transformer phase joint conductive rod; the acquisition device and Processor connection.

[0049] The processor of this embodiment is a personal computer (PC).

[0050] The heat source of the PTC heating device in this embodiment is 2 to 4 pieces of PTC ceramic constant temperature heating chips, the model selection is 220V / 260°C / 300W, and the specification is 56*56*7 mm. The main advantage of PTC ceramic constant temperature heating plate is the principle of non-electromagnetic heating, which will n...

Embodiment 2

[0069] The intelligent diagnosis method for transformer winding material provided in this embodiment includes the following steps:

[0070] S1: Open the relay to initialize the magnification and collect the initial thermoelectric potential and input it to the processor;

[0071] S2: adjust and set the initial thermoelectric potential range;

[0072] S3: The closed relay heats the phase connector of the transformer through the heating device;

[0073] S4: Collect the temperature signal of the transformer phase joint and input it to the processor;

[0074] S5: Determine whether the temperature at the phase joint of the transformer is within the preset temperature threshold range, and if so, control the magnification to collect the thermoelectric potential and input it to the processor;

[0075] S6: Calculate the thermoelectric potential holding voltage by the following formula:

[0076] U=S ab (T 1 -T 2 );

[0077] In the formula: S ab is the relative Seebeck coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com