Drying method of current transformer coil

A technology of current transformer and drying method, which is applied in the direction of coil manufacturing, drying solid materials, and combination of methods to dry solid materials, etc., can solve the problems of long drying time and high energy consumption, reduce drying time, improve product quality, and improve The effect of company capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

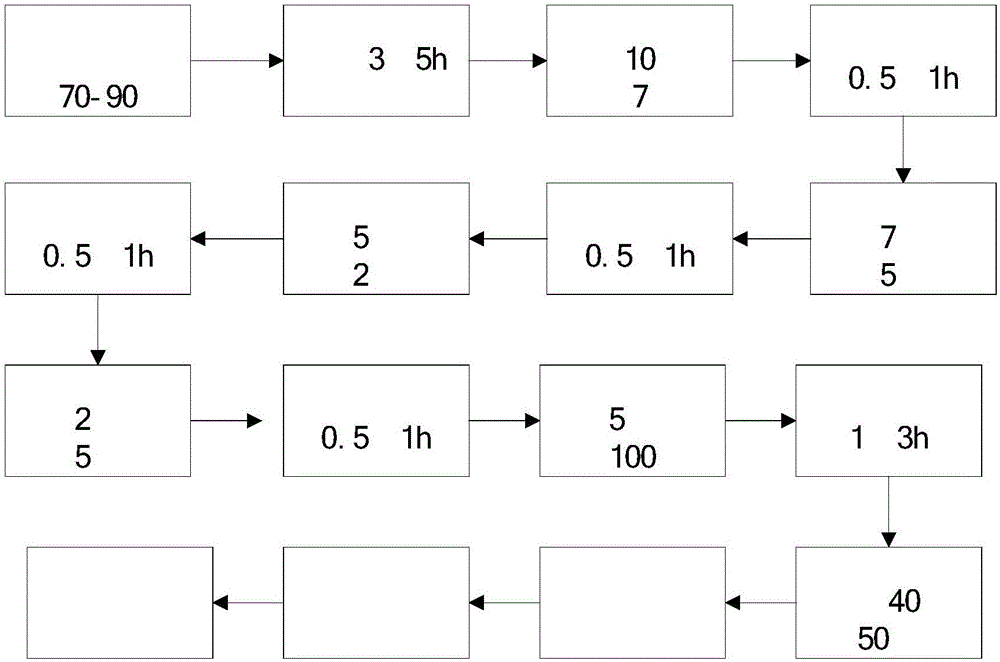

[0022] The drying method of the current transformer coil of the present embodiment, technological process is as follows figure 1 shown, including the following steps:

[0023] 1) Put the SF in the drying chamber 6 The current transformer coil is heated to 80°C and kept warm for 4 hours. During the heating and keeping warm process, the drying cavity is repeatedly pumped and inflated;

[0024] 2) Keep the temperature at 80°C, and vacuumize the drying chamber by gradient depressurization. First, vacuumize from normal pressure to 70kpa (0.25h), and keep the pressure for 1h; after keeping the pressure, fill it with dry air to 80kpa. Displace water vapor, then evacuate to 50kpa (time of 0.25h), hold pressure for 0.5h; after holding pressure, fill with dry air to 80kpa to replace water vapor, then evacuate to 20kpa (time of 0.25h), hold pressure for 0.5h ; After maintaining the pressure, fill it with dry air to 80kpa to replace the water vapor, then evacuate to 5ka (taking 0.25h), ...

Embodiment 2

[0027] The drying method of the current transformer coil of the present embodiment, technological process is as follows figure 1 shown, including the following steps:

[0028] 1) Put the SF in the drying chamber 6 Heat the coil of the current transformer to 70°C and keep it warm for 5 hours. During the process of heating and keeping warm, repeatedly pump and inflate the drying chamber;

[0029] 2) Keep the temperature at 70°C, and vacuumize the drying chamber by gradient depressurization. First, vacuumize from normal pressure to 70kpa (taking 0.25h), and keep the pressure for 1h; then evacuate from 70kpa to 50kpa (taking 0.25h ), hold the pressure for 1h; then vacuumize from 50kpa to 20kpa (0.25h), hold the pressure for 1h; then evacuate from 20kpa to 5ka (0.25h), hold the pressure for 1h; then evacuate from 5kpa to 100pa (use 1h ), the vacuum is maintained for 1h, and the pressure is released; in this process, the water vapor produced in the drying process is intermittently...

Embodiment 3

[0032] The drying method of the current transformer coil of the present embodiment, technological process is as follows figure 1 shown, including the following steps:

[0033] 1) Put the SF in the drying chamber 6 The current transformer coil is heated to 90°C and kept warm for 3 hours. During the heating and keeping warm process, the drying cavity is repeatedly pumped and inflated;

[0034]2) Keep the temperature at 90°C, and vacuumize the drying chamber by gradient step-down method. First, vacuumize from normal pressure to 70kpa (0.25h), and keep the pressure for 0.5h; then vacuumize from 70kpa to 50kpa (0.25h). h), hold the pressure for 0.5h; then vacuumize from 50kpa to 20kpa (0.25h), hold the pressure for 0.5h; then vacuumize from 20kpa to 5ka (use 0.25h), hold the pressure for 0.5h; then evacuate from 5kpa to 100pa (use time 1h), vacuum maintenance 2h; In this process, the water vapor produced in the drying process is intermittently replaced, and the specific operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com