Supercapacitor electrode plate and preparation method thereof

A technology for supercapacitors and pole pieces, applied in the field of supercapacitor pole pieces and their preparation, can solve the problems of slurry dripping and hindering applications, achieve high production efficiency, increase energy density and power density, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

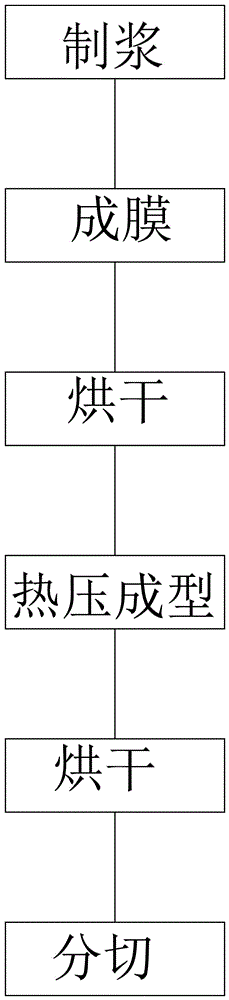

[0040] Example: a method for preparing a pole piece of a supercapacitor, the pole piece preparation comprises the following steps:

[0041] Ⅰ. Pulping, that is, putting 85% by weight of activated carbon, 10% of conductive carbon and 5% of binder into a planetary vacuum mixer and adding a solvent that is 4 times the weight of solid matter for stirring, dispersing and mixing to obtain a uniform supercapacitor slurry material.

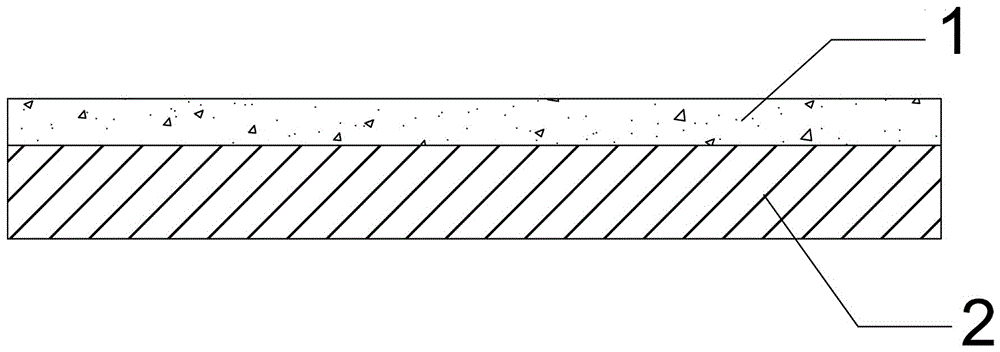

[0042] II. Forming a film, using an extrusion coater to coat the uniform slurry obtained in step I on the polyimide film carrier 2 to prepare a carbon film 1

[0043] Ⅲ, drying, step Ⅱ The polyimide film 2 coated with the carbon film 1 is dried in a tunnel oven, the thickness of the carbon film 1 after drying is 200 μm, and the content of the solvent is controlled at 6%;

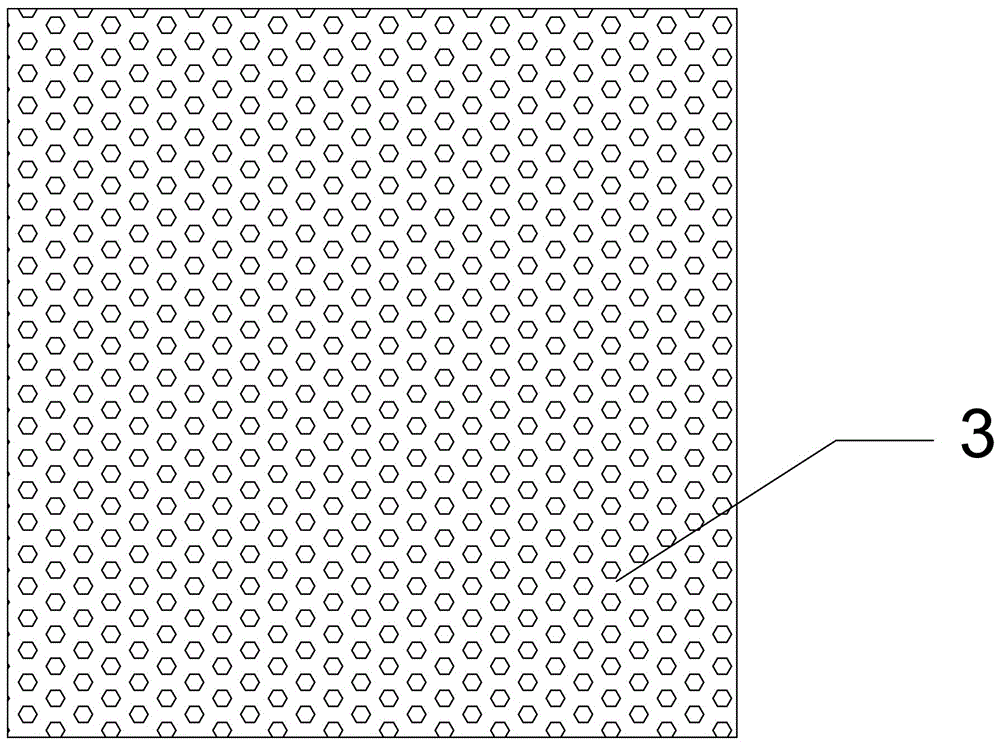

[0044] Ⅳ. Hot press molding, place the carbon film 1 dried in step Ⅲ on both sides of the aluminum current collector 3 with holes, and use 120°C and 200 tons of pressure to heat and ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com