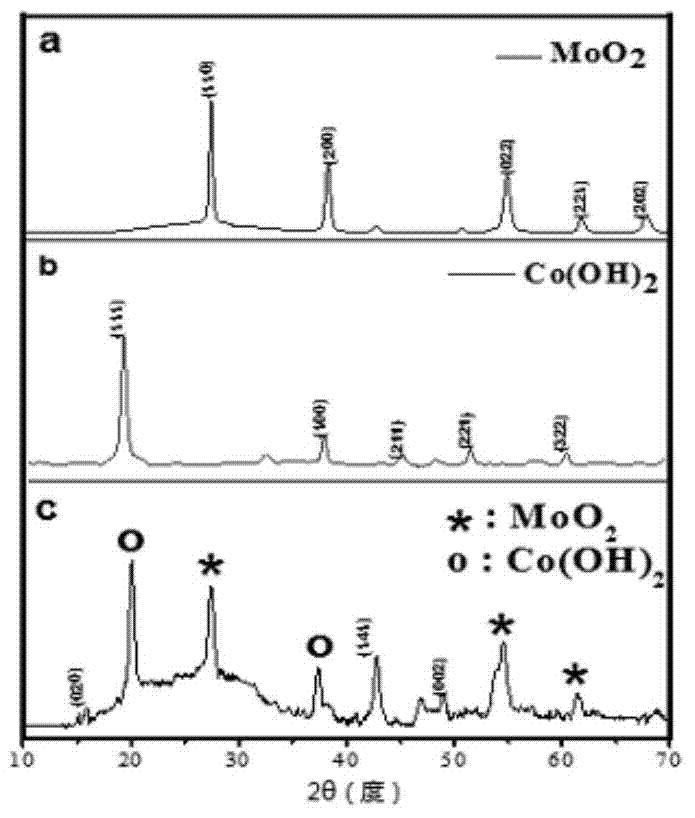

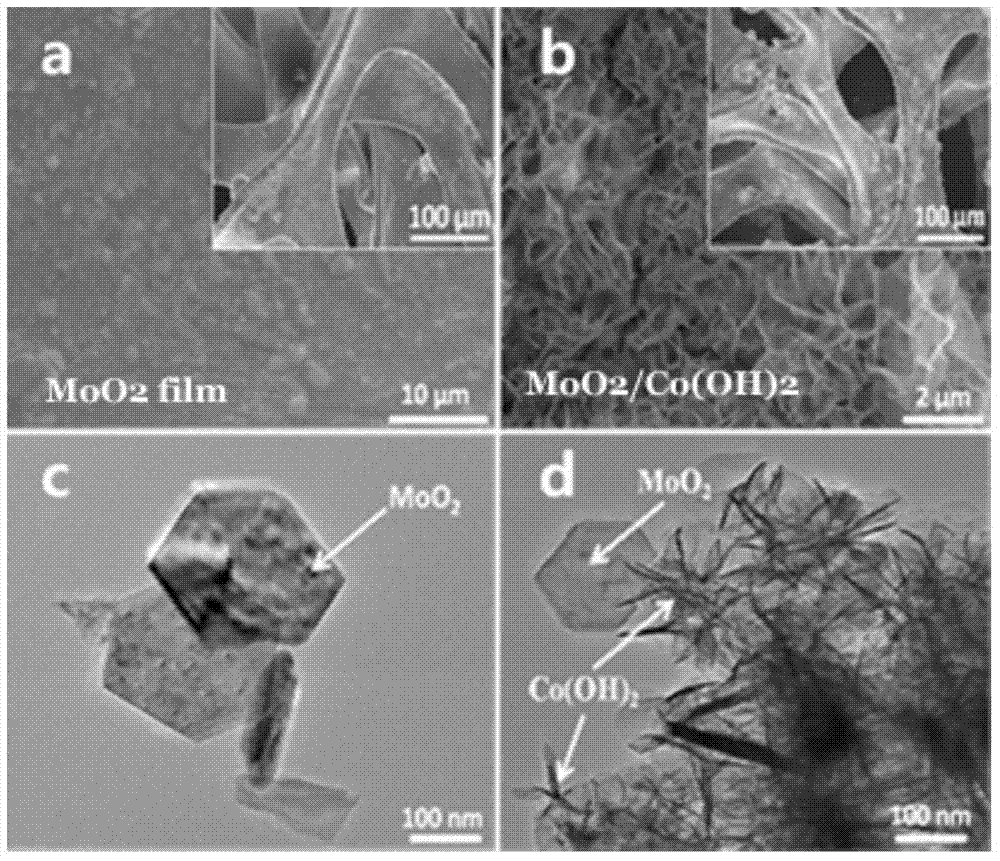

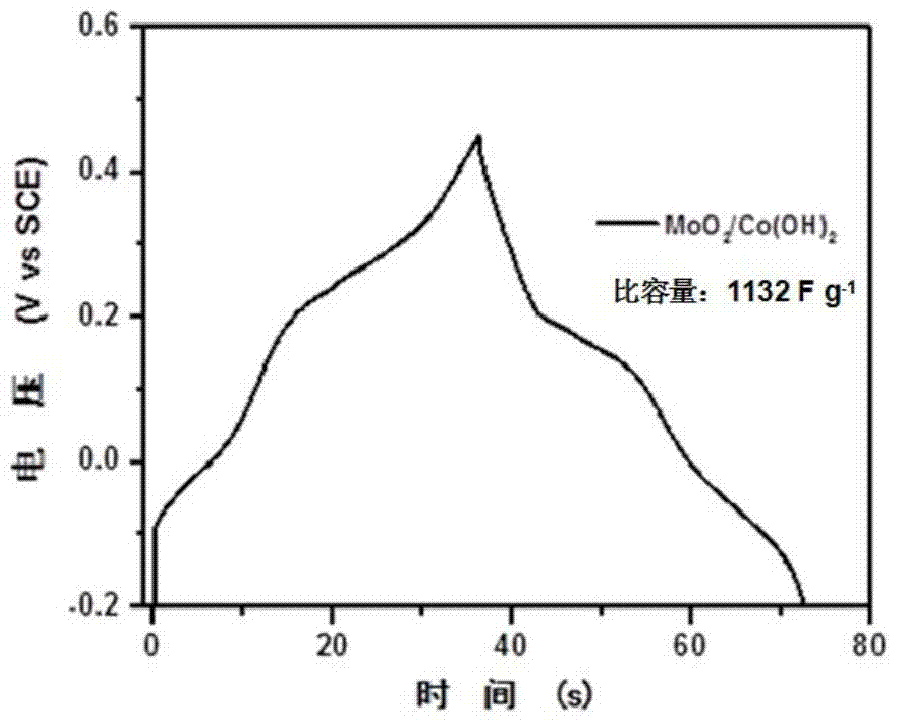

MoO2/Co(OH)2 grading composite nano-material, and preparation method and application thereof

A composite nanomaterial and nanosheet technology, which is applied in the field of MoO2/Co2 graded composite nanomaterials and their preparation, can solve the problems of poor cycle stability, low energy density, low electronic conductivity, etc., achieves low equipment requirements, and improves specific surface area. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] MoO 2 / Co(OH) 2 A method for preparing a hierarchical composite nanomaterial, comprising the steps of:

[0038] 1) Wash the nickel foam with 1mol / L nitric acid solution, and then wash it repeatedly with deionized water for use;

[0039] 2) Prepare 0.1mol / L (NH4 ) 6 Mo 7 o 24 4H 2 O and 1mol / L NH 4 Cl mixed solution;

[0040] 3) Add ammonia water dropwise to the mixed solution obtained in step 2), adjust the pH value to 8, and use the obtained solution as the precursor solution for the first electrochemical deposition;

[0041] 4) Use the nickel foam obtained in step 1) as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, at 10mA / cm 2 Under the current density and the voltage range of -0.4 ~ -0.8V, electrodeposited for 6 minutes, the MoO 2 Nano film nickel foam;

[0042] 5) Attach MoO to the obtained step 4) 2 The nickel foam of the nano-film is washed repeatedly with deioniz...

Embodiment 2

[0051] MoO 2 / Co(OH) 2 A method for preparing a hierarchical composite nanomaterial, comprising the steps of:

[0052] 1) Wash the nickel foam with 1mol / L nitric acid solution, and then wash it repeatedly with deionized water for use;

[0053] 2) Prepare 0.05mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 O and 0.5mol / L NH 4 Cl mixed solution;

[0054] 3) Add ammonia water dropwise to the mixed solution obtained in step 2), adjust the pH value to 10, and use the obtained solution as the precursor solution for the first electrochemical deposition;

[0055] 4) Using the nickel foam obtained in step 1) as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, conduct electrodeposition for 8 minutes to obtain MoO 2 Nano film nickel foam;

[0056] 5) Attach MoO to the obtained step 4) 2 The nickel foam of the nano-film is washed repeatedly with deionized water, and dried for later use;

[0057] 6) Prepare 0...

Embodiment 3

[0062] MoO 2 / Co(OH) 2 A method for preparing a hierarchical composite nanomaterial, comprising the steps of:

[0063] 1) Wash the nickel foam with 1mol / L nitric acid solution, and then wash it repeatedly with deionized water for use;

[0064] 2) Prepare 0.15mol / L (NH 4 ) 6 Mo 7 o 24 4H 2 O and 1.5mol / L NH 4 Cl mixed solution;

[0065] 3) Add ammonia water dropwise to the mixed solution obtained in step 2), adjust the pH value to 9, and use the obtained solution as the precursor solution for the first electrochemical deposition;

[0066] 4) Using the nickel foam obtained in step 1) as the working electrode, the platinum electrode as the counter electrode, and the saturated calomel electrode as the reference electrode, conduct electrodeposition for 3 minutes to obtain MoO 2 Nano film nickel foam;

[0067] 5) Attach MoO to the obtained step 4) 2 The nickel foam of the nano-film is washed repeatedly with deionized water, and dried for later use;

[0068] 6) Prepare 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com