Heat dissipating high-voltage connector

A high-voltage connector and heat-dissipating technology, applied in the direction of connection insulation, clamping/spring connection, etc., can solve the problems of increased surface contact resistance, inability to realize quick disassembly and assembly, low efficiency, etc., and achieve the effect of increasing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

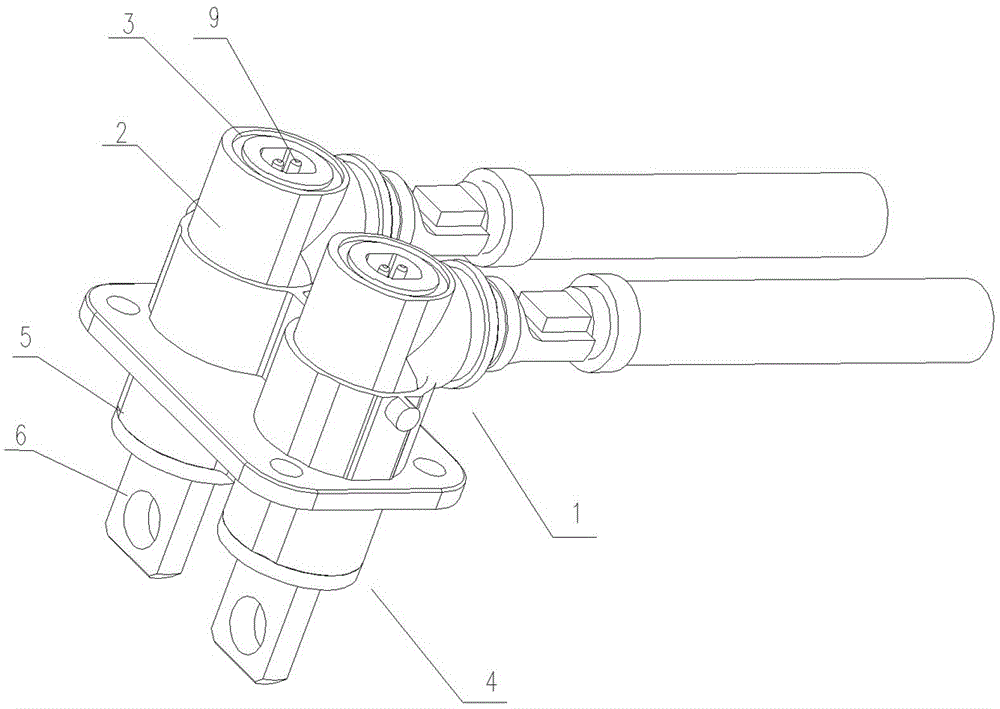

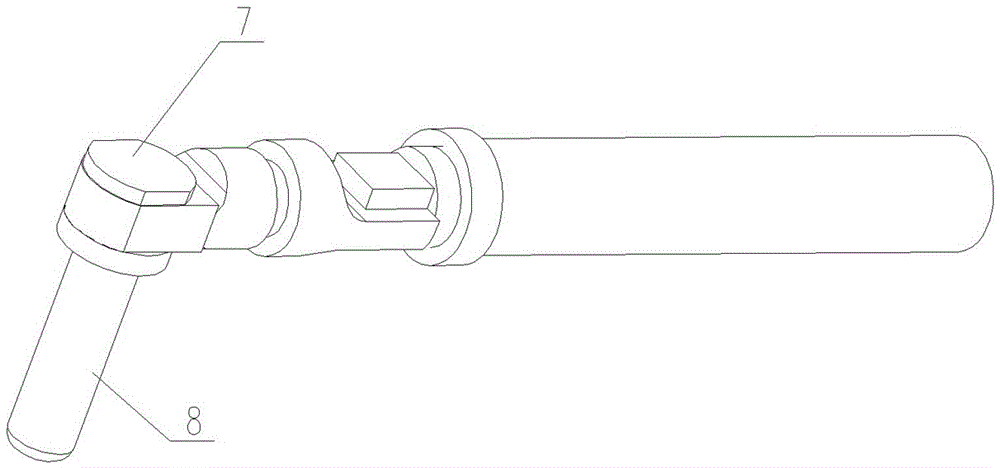

[0013] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The heat-dissipating high-voltage connector includes a matching high-voltage male-end plug 1 and a high-voltage female-end plug 4. The high-voltage male-end plug 1 includes a male-end plug body 8, a male-end housing 2, and a top cover 3. The male end plug main body 8 is arranged in the male end shell 2, and the top cover 3 is set on the upper end of the male end shell 2; the high-voltage female end plug 4 includes a female end plug body, a female end shell 5 and a bottom cover 6. The main body of the female end plug is arranged in the female end housing 5, and the bottom cover 6 is set on the lower end of the female end housing 5; between the non-contact end of the male end plug body and the top cover 3 and / or the non-contact of the female end plug body A thermally conductive insulating gasket 7 is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com