Uniform mixing technology of recycled solid wastes before sintering, and production line thereof

A solid waste and production line technology, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve problems such as mud compaction, product quality cannot be guaranteed, and affect the production process of iron ore powder agglomeration, so as to reduce production Cost, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

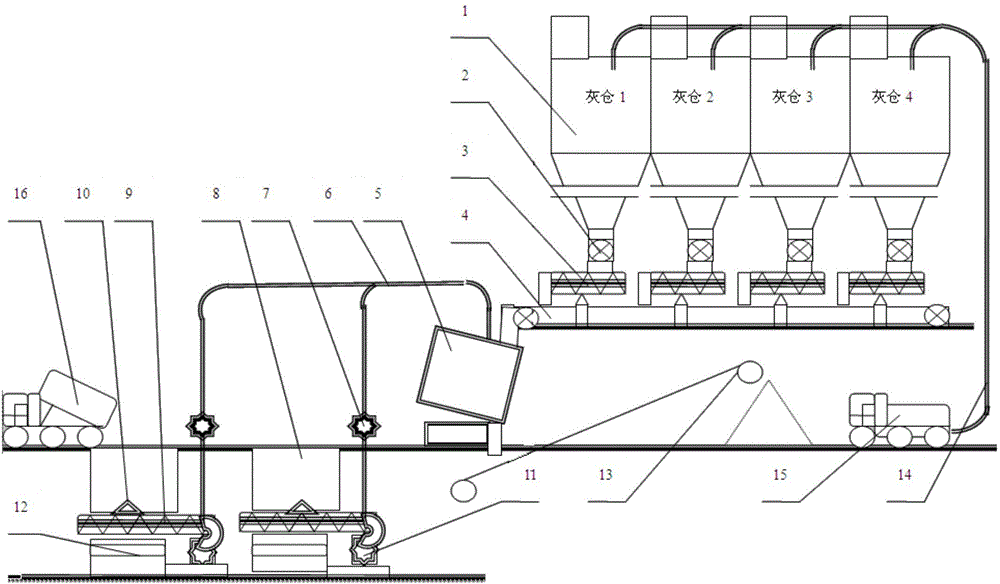

[0023] Such as figure 1 As shown, a kind of recycled solid waste is used in the mixing production line before sintering, including ash mixing workshop, mud mixing workshop, and mixing workshop. The ash mixing workshop conveys the dedusted ash with quantitative output to the mixing plant through a scraper conveyor 4 Workshop, the mud mixing workshop transports the quantitatively output mud to the mixing workshop through the mud conveying pipeline 6.

[0024] The ash distribution workshop includes ash conveying pipe 14, ash silo 1, quantitative feeder 2, screw scale 3, scraper conveyor 4. The input end of the ash conveying pipe 14 is temporarily connected to the dust tanker 15, and the output end of the ash conveying pipe 14 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com