Method for producing a porous structure in the layer structure of a semiconductor component and MEMS component with such a porous structural element

A technology of structural elements and porosity, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor electrostatic transducers, etc., and can solve problems affecting the electrical characteristics of integrated circuit components and damaging the functionality of integrated circuit components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

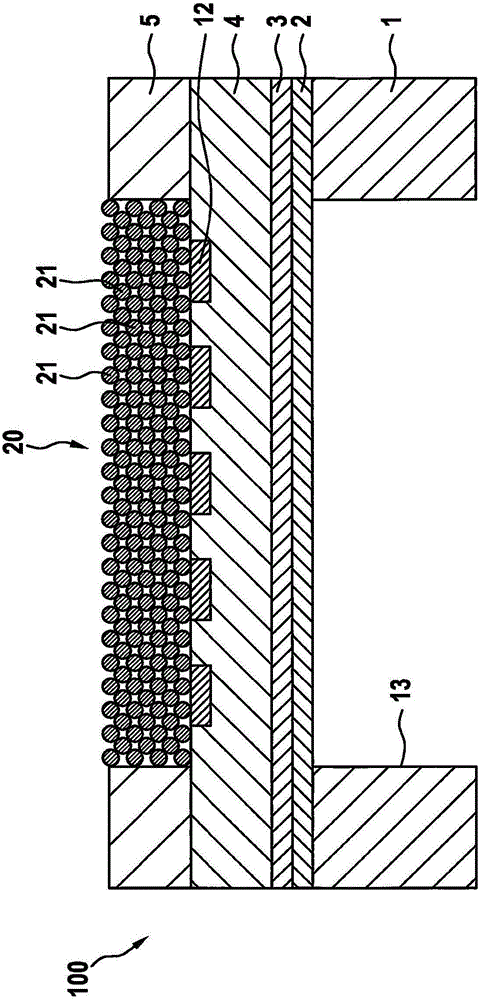

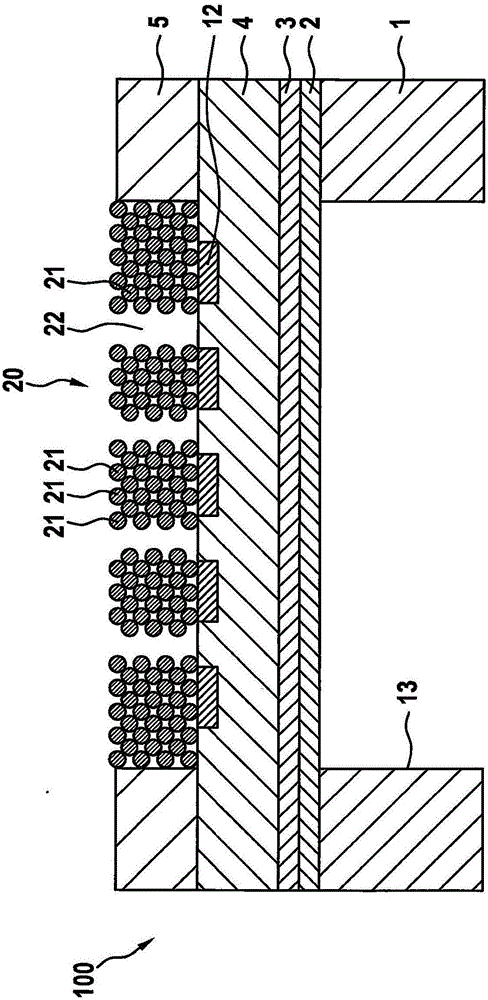

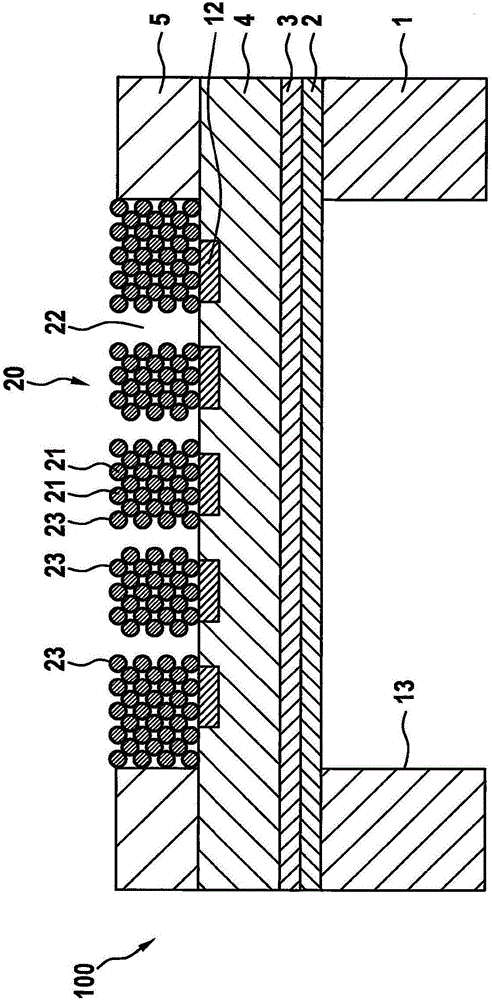

[0016] In the exemplary embodiment described here, the microphone structure of the MEMS microphone component is realized in a layer structure on the base substrate 1 . In this case, for example, a silicon substrate 1 may be involved.

[0017] In a first process step, the substrate surface is provided with a silicon oxide layer 2 . The silicon oxide layer 2 serves on the one hand as an etch stop layer for the backside etching process, wherein the base substrate 1 is completely removed in a defined region, ie the diaphragm region, in order to expose the microphone diaphragm 10 on the rear side. On the other hand, the silicon oxide layer 2 acts as electrical insulation between the base substrate 1 and the polysilicon layer 3 applied on the silicon oxide layer 2 . In a subsequent process step, the microphone diaphragm 10 is realized in the polysilicon layer 3 , which also serves as the diaphragm electrode of the microphone capacitor.

[0018] Before this, however, a thick silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com