Method for preparing 3-amino-4,4,4-trifluorocrotonate

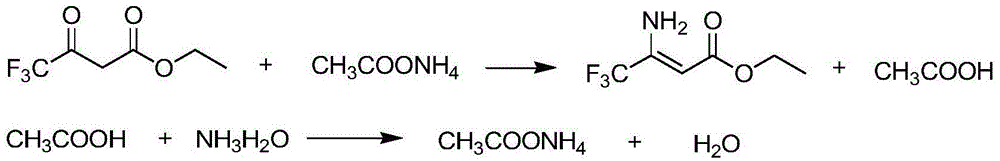

A technology of ethyl trifluorocrotonate and ethyl trifluoroacetoacetate, which is applied in the field of preparation of ethyl 3-amino-4,4,4-trifluorocrotonate, can solve the problems of large equipment investment and achieve cost Economical, high yield, high content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The volume of the amination reaction kettle is 1000L, equipped with stirring, thermometer, metering tank and condenser. Add 368.0kg (2.0kmol) ethyl 4,4,4-trifluoroacetoacetate into the reaction kettle through the metering tank, and raise the temperature to 90°C after the addition is complete. Then throw in 323.4kg (4.2kmol) of ammonium acetate, and keep warm at 90°C for 3 hours after throwing in. Cool the temperature of the reaction solution to 30°C, stop stirring, and let stand for 30 minutes. The reaction solution is divided into two layers, the lower layer is an organic phase, the weight is 359.6kg, the content of the product 3-amino-4,4,4-trifluorocrotonate ethyl ester is 98.2%, and the yield is 96.5%; the upper layer is an aqueous phase, and the water The phase weight is 330.6kg, and the content of acetic acid in the water phase is 36.3%.

[0023] The resulting 359.6kg water phase was transferred to a 1000L neutralization reactor equipped with stirring, thermomet...

Embodiment 2

[0025] The volume of the amination reaction kettle is 1000L, equipped with stirring, thermometer, metering tank and condenser. Add 368.0kg (2.0kmol) ethyl 4,4,4-trifluoroacetoacetate into the reaction kettle through the metering tank, and raise the temperature to 100°C after the addition is complete. Then throw in 308.0kg (4.0kmol) of ammonium acetate, and keep warm at 80°C for 4 hours after throwing in. Cool the temperature of the reaction solution to 40°C, stop stirring, and let stand for 30 minutes. The reaction solution is divided into two layers, the lower layer is an organic phase, the weight is 357.6kg, the content of the product 3-amino-4,4,4-trifluorocrotonate ethyl ester is 97.7%, and the yield is 95.4%; the upper layer is an aqueous phase, water The phase weight is 317.5 kg, and the content of acetic acid in the aqueous phase is 38.5%.

[0026] The resulting 317.5kg water phase was transferred to a 1000L neutralization reactor equipped with stirring, thermometer, ...

Embodiment 3

[0028] The volume of the amination reaction kettle is 1000L, equipped with stirring, thermometer, metering tank and condenser. Add 414.0kg (2.25kmol) ethyl 4,4,4-trifluoroacetoacetate into the reaction kettle through the metering tank, and raise the temperature to 95°C after the addition is complete. Then drop into the ammonium acetate solid obtained in the embodiment 1 of 366.0kg (4.75kmol) and embodiment 2 (weight respectively accounts for 50%), after throwing, insulation 3 hours under 95 ℃. Cool the temperature of the reaction solution to 35°C, stop stirring, and let stand for 30 minutes. The reaction solution is divided into two layers, the lower layer is an organic phase, the weight is 403.5kg, the content of the product 3-amino-4,4,4-trifluorocrotonate ethyl ester is 98.2%, and the yield is 96.2%; the upper layer is an aqueous phase, and the water The weight of the phase is 375.4 kg, and the content of acetic acid in the water phase is 36.8%.

[0029] The resulting 403...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com