Natural gas filling method

A natural gas and cooling device technology, which is applied in container filling methods, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., can solve the problem of low effective volume utilization of vehicle-mounted gas cylinders, and reduce excessive power consumption, The effect of improving space utilization and reducing the number of filling times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

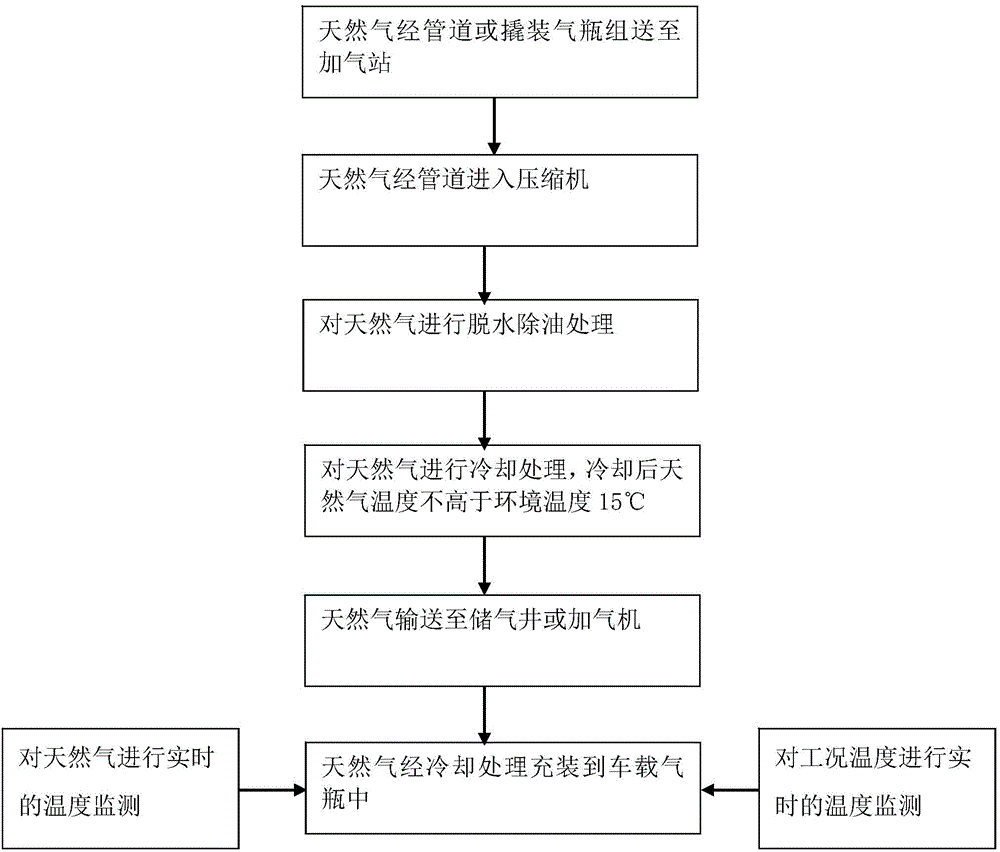

[0017] Such as figure 1 As shown, a natural gas filling method,

[0018] (1) Natural gas is sent to the gas filling station through pipelines or skid-mounted gas cylinders;

[0019] (2) Natural gas enters the compressor through the pipeline and is pressurized to a filling pressure of 20Mpa;

[0020] (3) Carry out dehydration and oil removal treatment to natural gas;

[0021] (4) Cool the natural gas, and the temperature of the natural gas after cooling is not higher than the ambient temperature by 15°C, that is, T 天然气 ≤T 环境 +15℃, where T 天然气 is the natural gas temperature after cooling, T 环境 is the ambient temperature;

[0022] (5) Natural gas is transported to gas storage wells or gas dispensers, and metered;

[0023] (6) Natural gas is cooled by a cooling device and then filled into vehicle-mounted gas cylinders. During the cooling process, the natural gas temperature ranges from 40°C below the ambient temperature to 0°C below the ambient temperature, that is, the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com