Multi-functional BMC heating floor

A multi-functional, floor technology, applied in hot water central heating system, household heating, heating system, etc., can solve the problems of high structural floor, unfavorable bathroom drainage, etc., to achieve strong decoration, comfortable use and easy installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

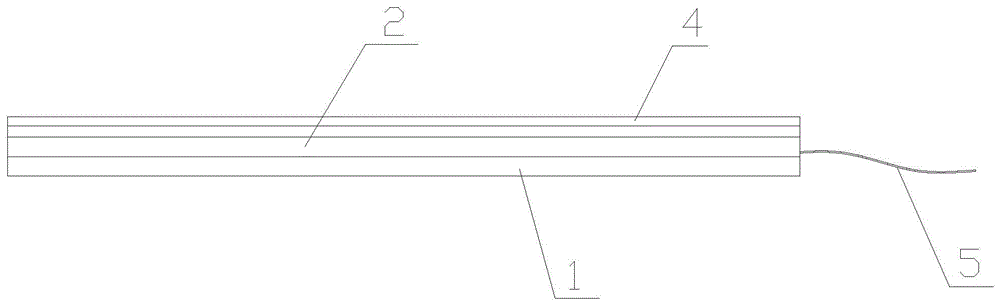

[0016] Such as figure 1 As shown, the multifunctional BMC heating floor includes a floor body 1 and a heating device, the heating device is a heating cable 2, and the heating cable 2 is passed through the floor body 1, and the floor body 1 is made of BMC material. The BMC material is molded to form a wire hole through which the heating cable 2 is passed, and the heating cable 2 is connected to an external power supply through a wire 5 .

Embodiment 2

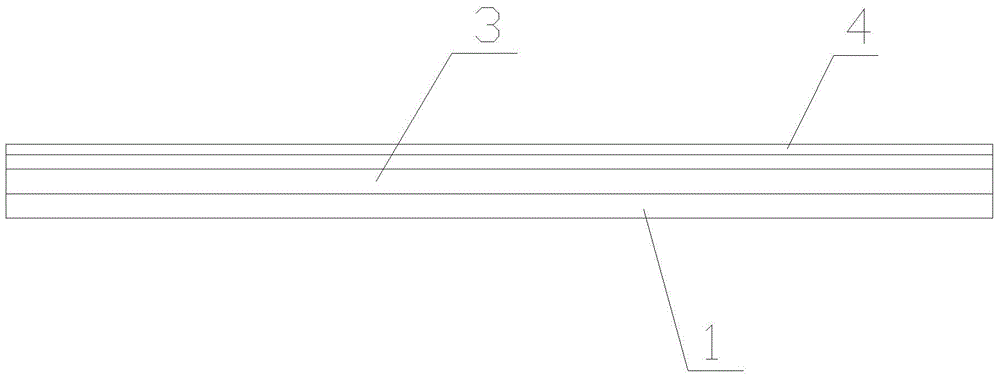

[0019] Such as figure 2 As shown, the multifunctional BMC heating floor includes a floor body 1 and a heat conduction device, and the heat conduction device includes a water delivery pipeline 3, which is arranged in the floor main body 1, and the water delivery pipeline 3 communicates with a device for heating water. The floor main body 1 is made of BMC material, and the BMC material is molded to form a water delivery pipe, and a layer of decorative material layer 4 is provided on the surface of the floor main body 1 . The present invention can also adopt another embodiment, that is, the water delivery pipeline 3 is laid under the floor main body 1 .

[0020] The invention adopts an integral molding structure, and the BMC material is hot-pressed and formed in a mold at one time. The BMC is a good electrical insulation material and has excellent electrical packaging performance. The decorative material layer 4 can obtain different artificial marble effects through the matchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com