Bottom protrusion of heat-insulation furnace

The technology of holding furnace and furnace mouth is applied in the field of aluminum melting and casting aluminum kiln, which can solve the problems of high temperature of aluminum liquid surface and much oxidized slag, and achieve the effects of increasing volume, high operation rate and 100% metal yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

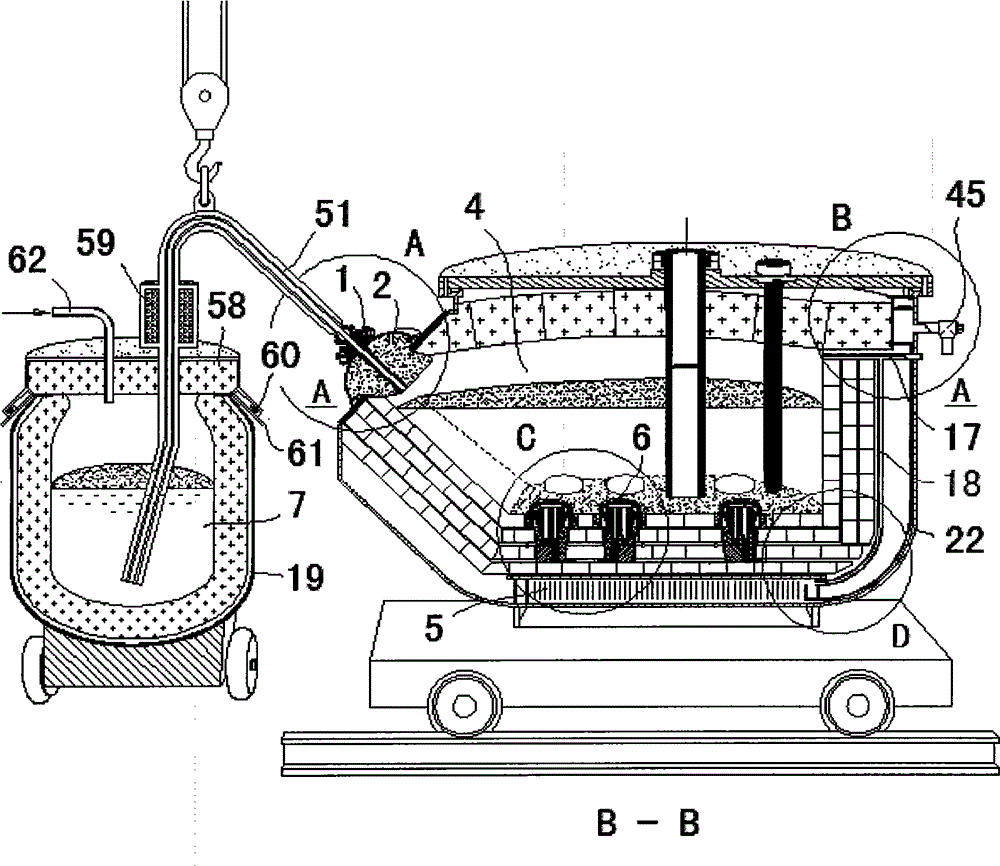

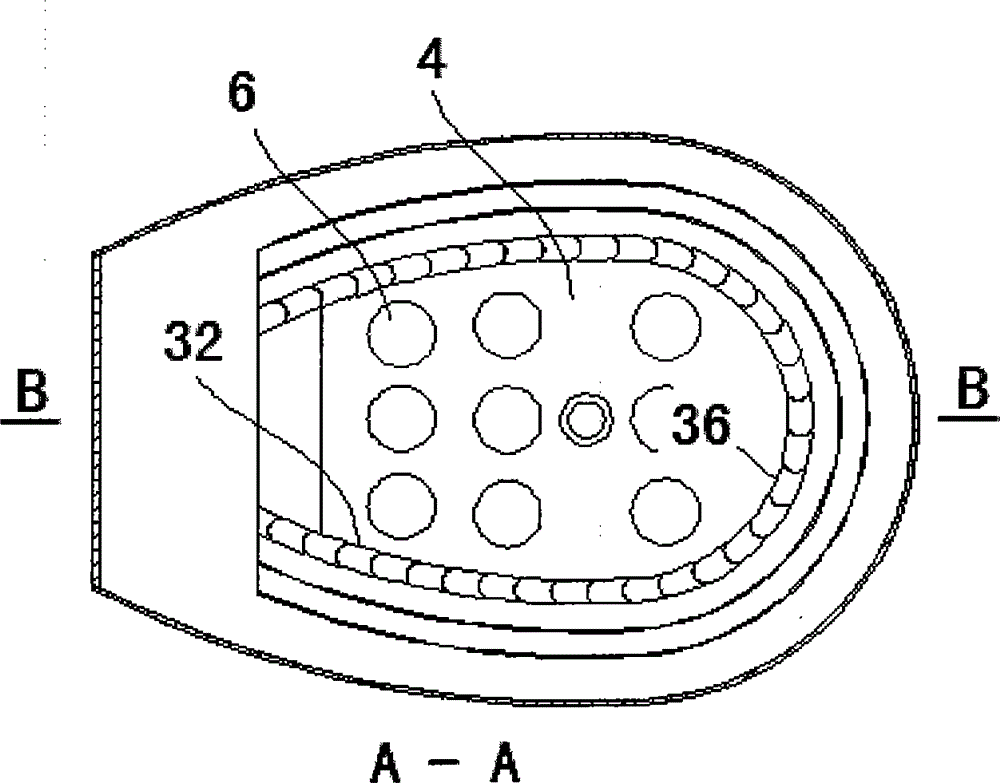

[0047] attached Figure 1-2 Shown is the general configuration of the invention.

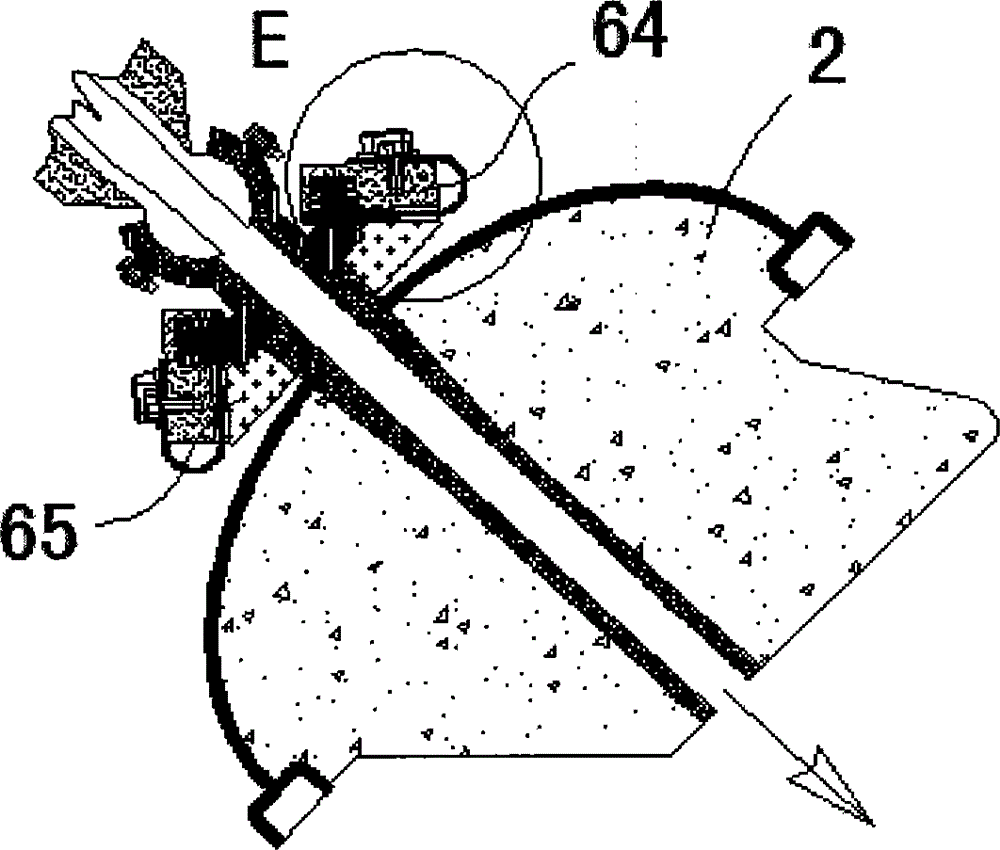

[0048] attached Figure 3-5 Shown is the gate valve configuration.

[0049] The slideway 46 of the door valve 1 is inserted or pulled out the joint plate 57, the joint plate 57 has a ball socket movable inlaid with the ball head of the door pipe 51 to connect the door pipe 51, a section of the door pipe 51 is connected in the transfer tank 7, the slideway of the door valve 1 Two oil cylinders 50 are arranged at both ends of 46, and the two oil cylinders 50 push the joint plate 57 and a blind plate 48 in opposite directions, push the joint plate 57 to move to the center of the slideway 46, and the pipe hole of the joint plate 57 and the hole of the gate valve 1 pass through the gate valve 1 to open. The oil cylinder 50 pushes the blind plate 48, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com