A color photosensitive resin composition, color filter and display device comprising the same

A photosensitive resin and composition technology, applied in optics, instruments, filters, etc., can solve the problems of inability to obtain brightness, decreased brightness, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0223] The preparation method of the colored photosensitive resin composition of this invention is as follows.

[0224] First, the colorant (A) is mixed with the solvent (F) and dispersed using a bead mill or the like until the average particle diameter of the pigment becomes about 0.2 μm or less. Here, the pigment dispersant (a2) and a part or all of the alkali-soluble resin (B) may be mixed with the solvent (F), and dissolved or dispersed therein, if necessary.

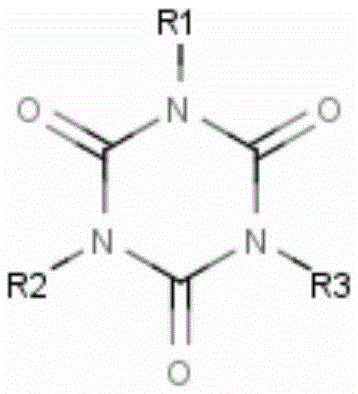

[0225] The remaining alkali-soluble resin (B), the photo- or thermally polymerizable compound (C) including the isocyanurate compound of Chemical Formula 1, the photopolymerizable monomer (D) are further added to the mixed coloring material ), a photopolymerization initiator (E), an additive (G) as required, and further adding a solvent (F) so as to have a specific concentration, and the colored photosensitive resin composition of the present invention can be prepared.

[0226] In addition, the present invention pr...

Synthetic example 1

[0239] 43.4 parts by weight of isocyanuric acid and 500 parts by weight of toluene were put into a 4-neck round bottom flask including a cooling pipe and a stirrer, and while stirring the mixture, 0.4 parts by weight of hydroxide was introduced thereto Barium, 27.5 parts by weight of formaldehyde and 29.1 parts by weight of acrylic acid.

[0240] The reflux reaction continued for 12 hours and was monitored by TLC to identify completion of the reaction.

[0241] After the temperature of the reactor was lowered to room temperature, the organic solution was washed three times with water and ethyl acetate, and the organic layer was separated and dried over anhydrous magnesium sulfate. The solvent was removed under vacuum to obtain 83.2 parts by weight (83% yield) of the compound of the following Chemical Formula 5 as a white solid.

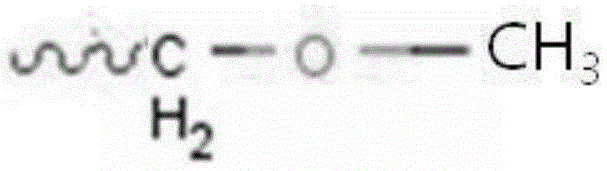

[0242] [Chemical formula 5]

[0243]

Synthetic example 2

[0245] 35.9 parts by weight of isocyanuric acid and 500 parts by weight of toluene were put into a 4-neck round bottom flask including a cooling pipe and a stirrer, and while stirring the mixture, 0.4 parts by weight of hydroxide was introduced thereto Barium, 10.1 parts by weight of formaldehyde, and 54.0 parts by weight of acrylic acid.

[0246] The reflux reaction continued for 12 hours and was monitored by TLC to identify completion of the reaction.

[0247] After the temperature of the reactor was lowered to room temperature, the organic solution was washed three times with water and ethyl acetate, and the organic layer was separated and dried over anhydrous magnesium sulfate. The solvent was removed under vacuum to obtain 85.1 parts by weight (85% yield) of the compound of the following Chemical Formula 6 as a white solid.

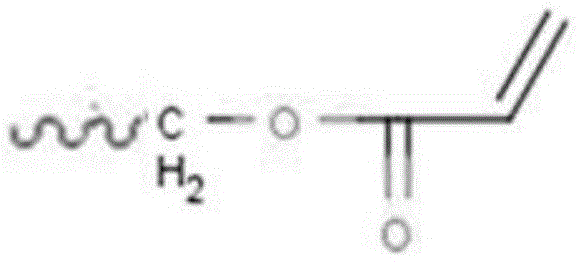

[0248] [Chemical formula 6]

[0249]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com