Three-dimensional automatic rotating seedling-cultivating frame and seedling-cultivating method thereof

A technology of automatic rotation and seedling raising rack, applied in the fields of botanical equipment and methods, planting substrate, horticulture, etc., can solve the problems of poor growth of tobacco seedlings, insufficient time, large power consumption, etc., to improve the ground utilization rate, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

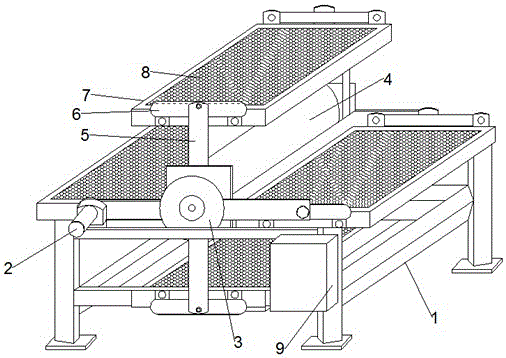

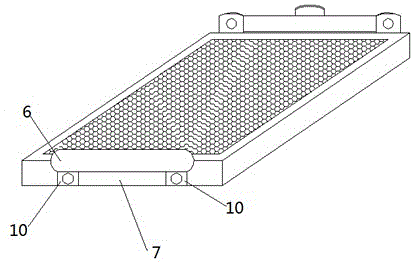

[0031] The three-dimensional automatic rotary seedling raising frame includes a frame 1, a four-bar balance mechanism, and a floating disc 8. The four-bar balance mechanism is arranged on the frame 1, and the four-bar balance mechanism is provided with a floating disc 8, and the four-bar balance mechanism The mechanism is arranged on the frame 1 to ensure that the four-bar balance mechanism is always kept horizontal and upward under the action of gravity, so that the floating plate 8 in the seedling tray 7 is level and will not tip over, and the four-bar balance mechanism surrounds the central axis of the frame 1 Rotate, allow the seedling in the floating dish 8 to be exposed to sufficient sunlight, improve the ground utilization rate.

[0032] As a preference, the two ends of the frame 1 are equipped with a bearing seat 3, the bearing seat 3 is provided with a transmission shaft 4, the bearing seat 3 is used to support and fix the transmission shaft 4, and one end of the trans...

Embodiment 2

[0037] The three-dimensional automatic rotary seedling raising frame includes a frame 1, a four-bar balance mechanism, a floating disc 8, a bearing seat 3, a transmission shaft 4, a reduction motor 2, and a rotary arm 5, and the two ends of the frame 1 are equipped with a bearing seat 3, a bearing Seat 3 is provided with transmission shaft 4, and transmission shaft 4 one end links to each other with reduction motor 2 through gear, and transmission shaft 4 two ends are equipped with revolving arm 5, and revolving arm 5 two ends are equipped with four-bar balance mechanism, and four-bar balance mechanism is equipped with There is a floating disc 8, and a supporting bearing is arranged in the bearing seat 3 arranged on the frame 1. The bearing seat 3 fixes the outer ring of the bearing, and the outer ring remains motionless, always consistent with the direction of transmission, and maintains balance to support the bearing The upper sleeve is provided with a transmission shaft 4, a...

Embodiment 3

[0042] The two ends of the frame 1 are equipped with bearing housings 3, the bearing housings 3 are used to support the transmission shaft 4, one end of the transmission shaft 4 is connected with the reduction motor 2, the reduction motor 2 drives the transmission shaft 4 to rotate, and the reduction motor 2 provides the driving force for the transmission shaft 4 to rotate. Power, transmission shaft 4 two ends are equipped with rotary arm 5, are equipped with four-bar balance mechanism on the two ends on the rotary arm 5, and seedling raising tray 7 is hung on balance bar left and right ends, and rotary arm 5 is hinged with four-bar balance mechanism, four The rod balance mechanism is hinged with the boom, because the seedling tray 6 is always kept horizontal during the rotation, which ensures that the seedling tray 7 does not tip over during the rotation, and a floating tray 8 is placed inside the seedling tray 7, and the floating tray 8 is made of foaming material , it is ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com