Automatic leavening and steaming integrated machine

An all-in-one machine, waking and steaming technology, applied in baking, dough fermenter, food science, etc., can solve the problems of low productivity, large floor space, high energy consumption, etc., to reduce steam loss, save floor space, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

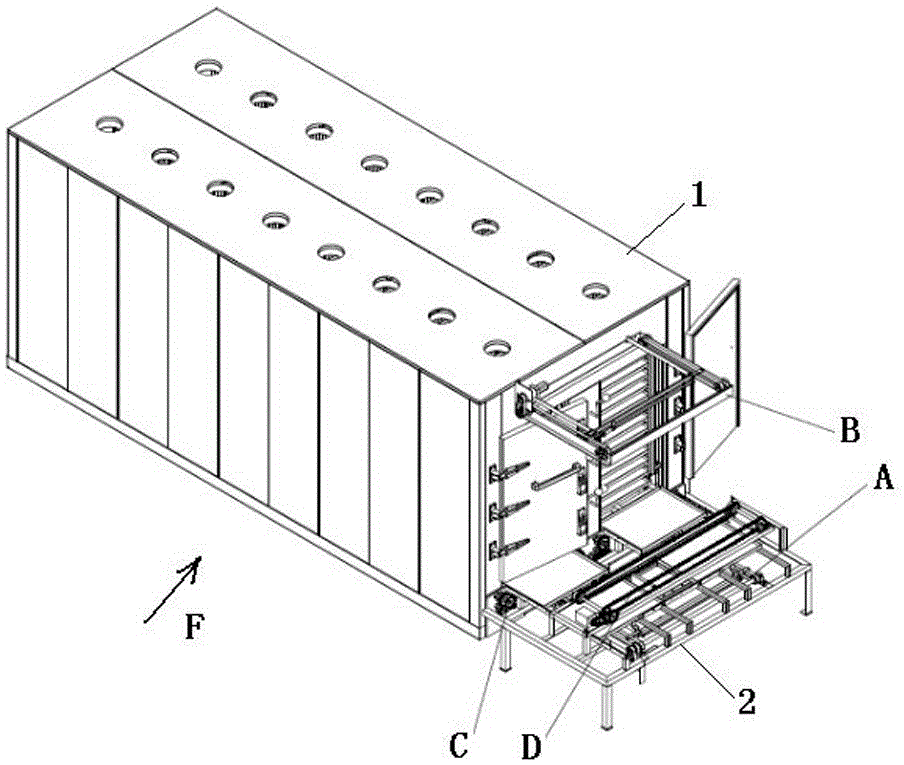

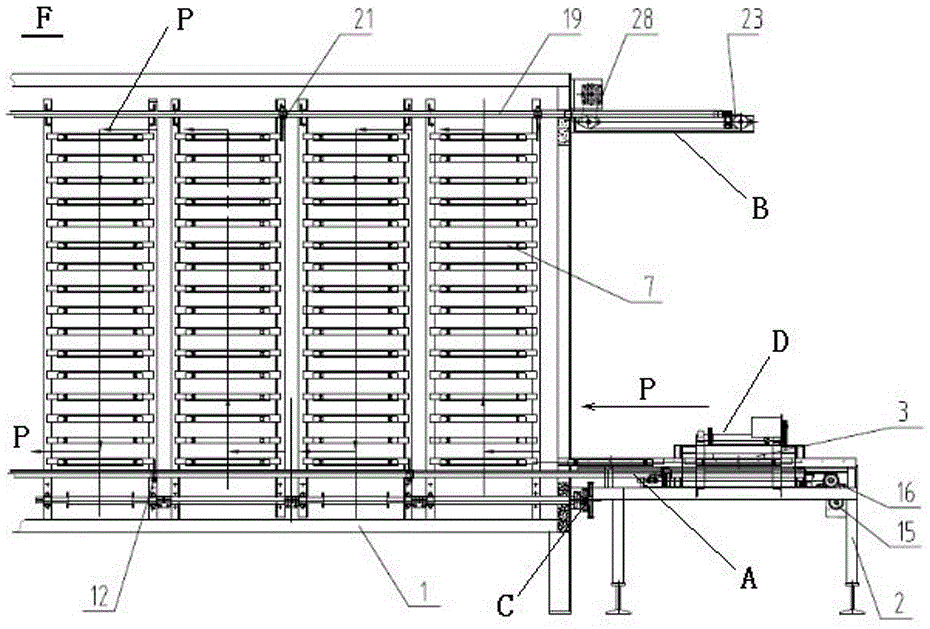

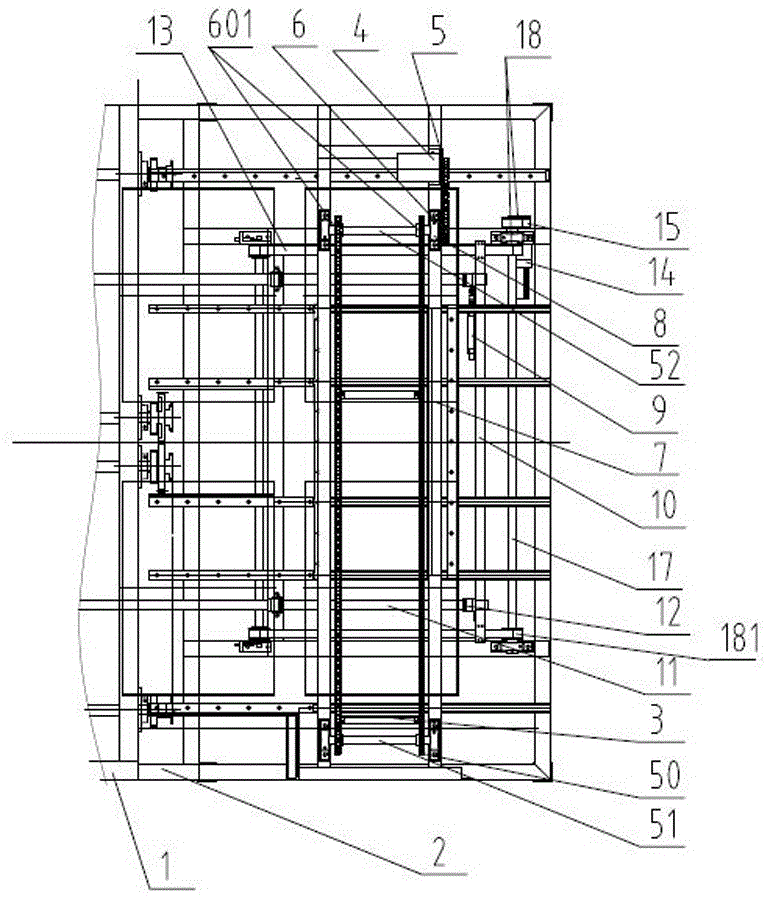

[0012] see Figure 1-Figure 6 , the present invention is an automatic waking and steaming integrated machine, which is characterized in that it includes waking and steaming room 1, frame 2, lower pushing plate device A, upper pushing plate device B and lifting device C, and inside waking and steaming room 1 is provided with The n-shaped frame 101 is provided with at least two lifting positions for the steaming tray 7 to be lifted up and down independently, and the number of the lifting positions is an even number. The bottom and top of the frame 101 are respectively provided with a lower push plate device A and an upper push plate device B; a frame 2 is provided at the lower part outside the entrance end of the wake-up steaming room 1, and one end of the lower push plate device A extends Above the frame 2, it is used to transport the steaming tray 7 to the bottom of the first lifting position of the inner frame of the steaming room 1; a lifting device C is provided on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com