De-dusting demisting device

A technology of demisting device and dedusting component, which is applied in the direction of combination device, using liquid separating agent, dispersing particle separation, etc., can solve the problems of no fine dust removal, small dewatering specific area, low dewatering efficiency, etc., and achieves good absorption effect, The effect of short flow line and high dewatering and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The above-mentioned technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention.

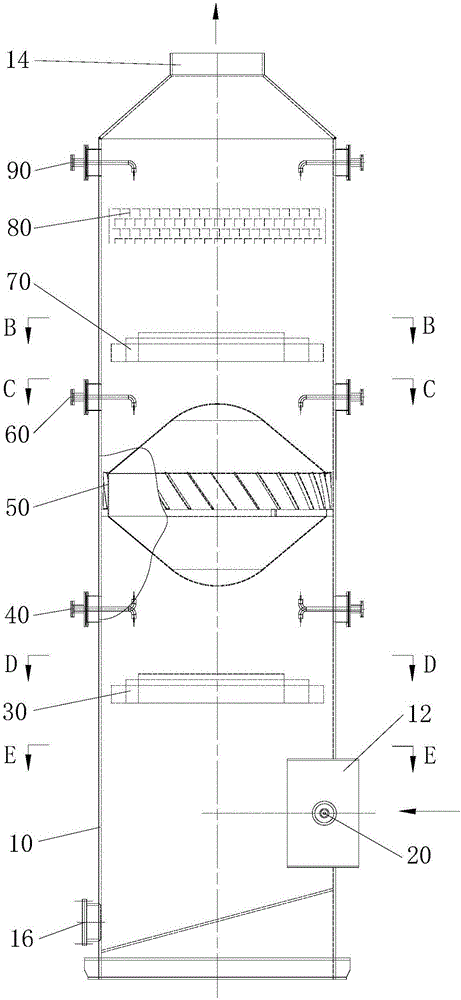

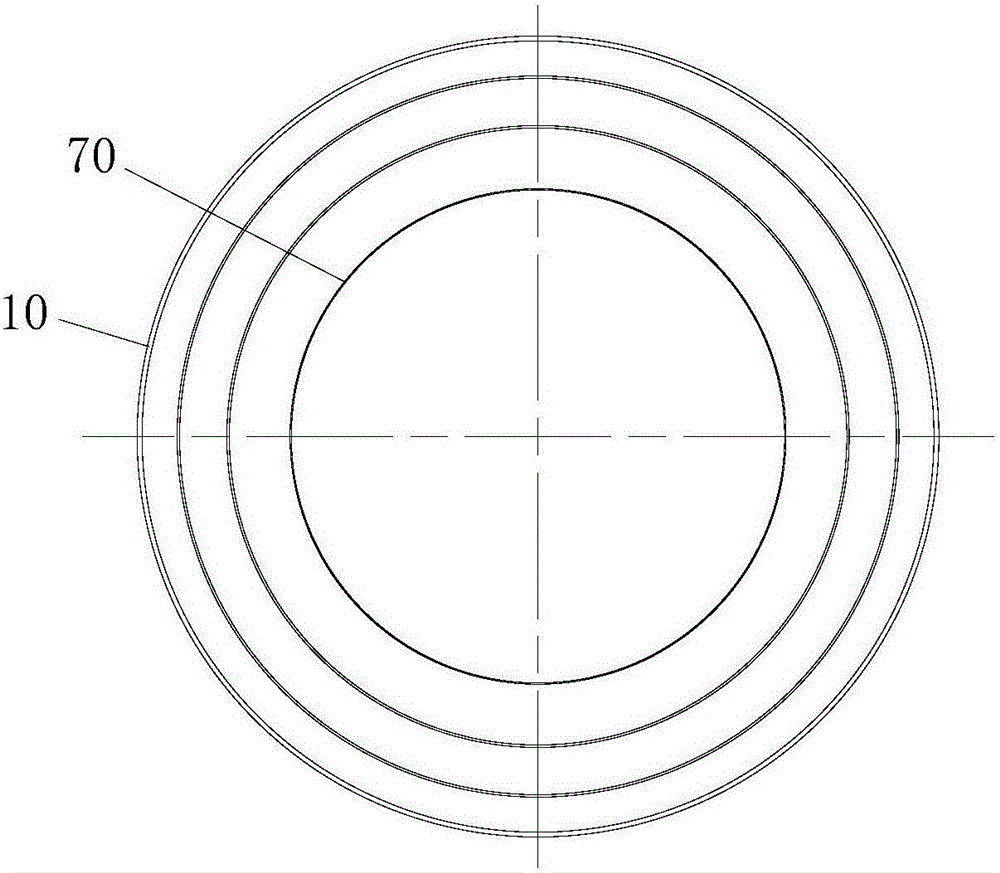

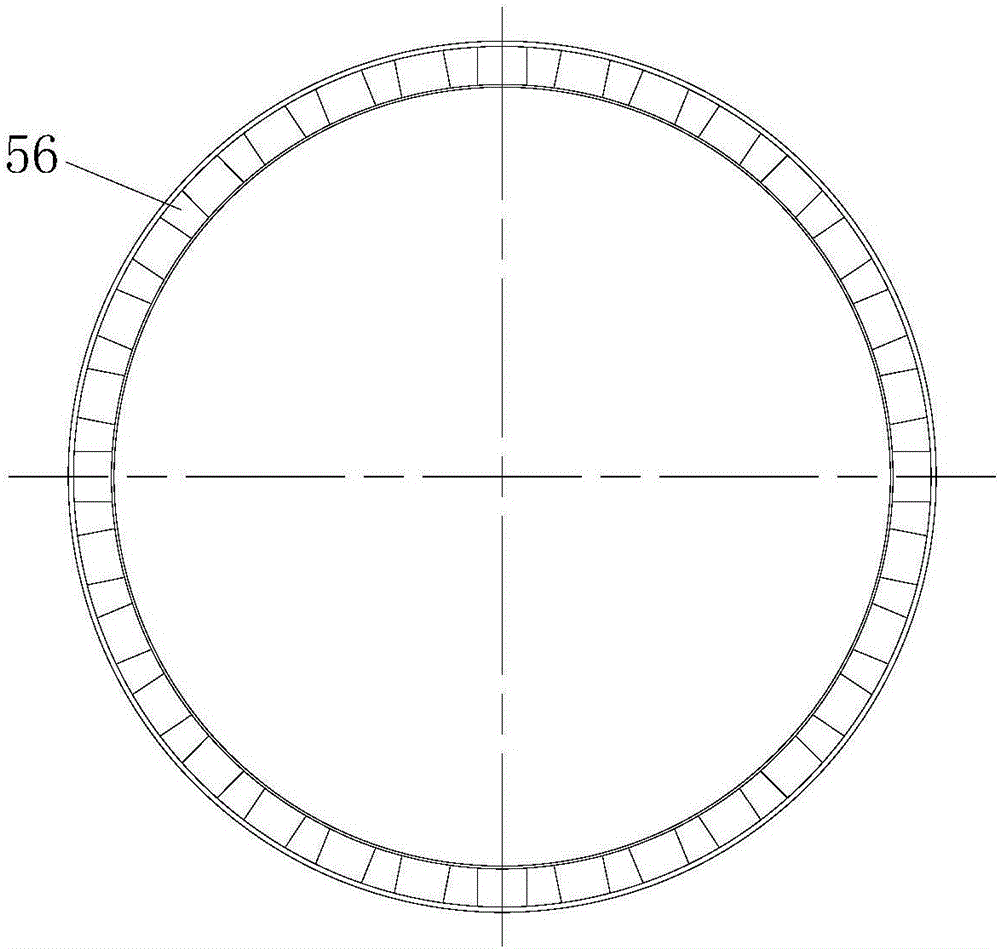

[0060] see Figure 1 to Figure 5 As shown, the present invention proposes a dust and mist removal device. The dust and mist removal device includes a vertically arranged cylinder body 10. The cylinder body 10 has an inner cavity. The cylinder body 10 is provided with an inlet 12 and an outlet 14, and the inlet 12 is for flue gas to enter. Inner cavity, the outlet 14 outputs the purified gas in the inner cavity; the inlet 12 is arranged on the side wall of the cylinder 10, and is located below the outlet 14, and a sewage pipe 16 is arranged below the inlet 12, and the sewage pipe 16 communicates with the inner cavity and External sedimentation tank.

[0061] The dust and mist removal device also incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com