A forming device and method for small-height convex parts

A technology of small height and small parts, which is applied in the field of forming devices for small height convex parts, can solve the problems of time-consuming and laborious manual trimming and replacement, manual trimming space is not necessarily regular, and the trimming process is not necessarily orderly, so as to improve self-processing ability and reduce Manual shape correction to meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

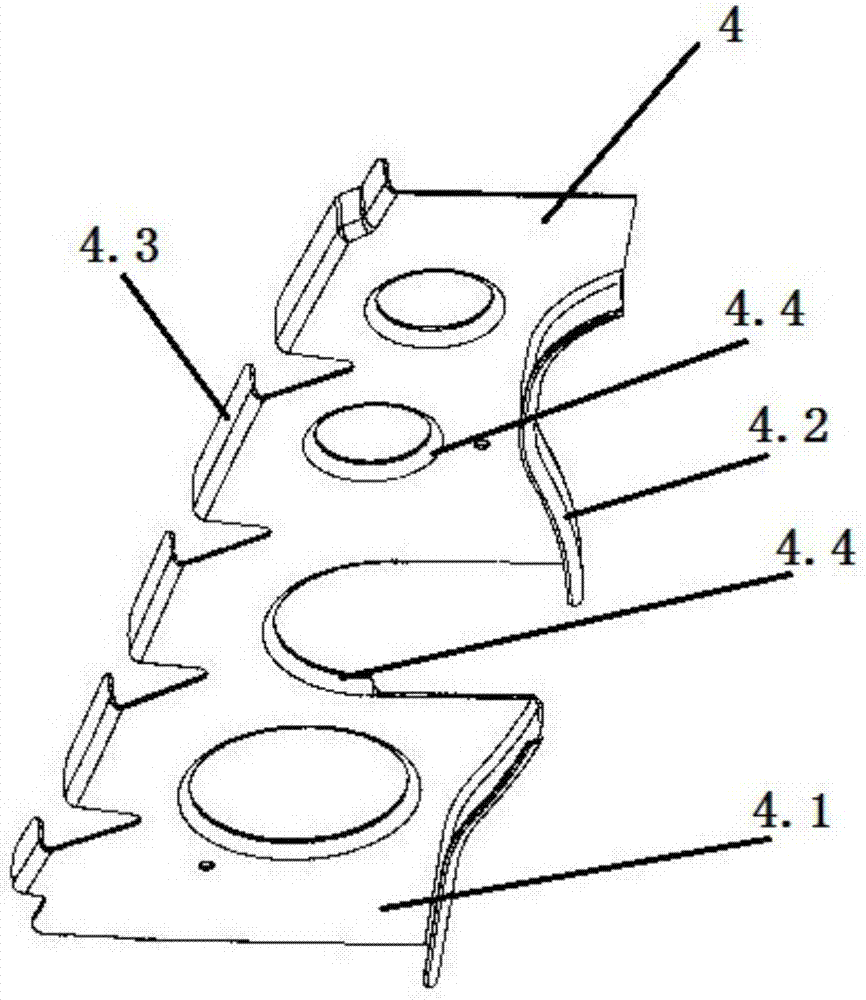

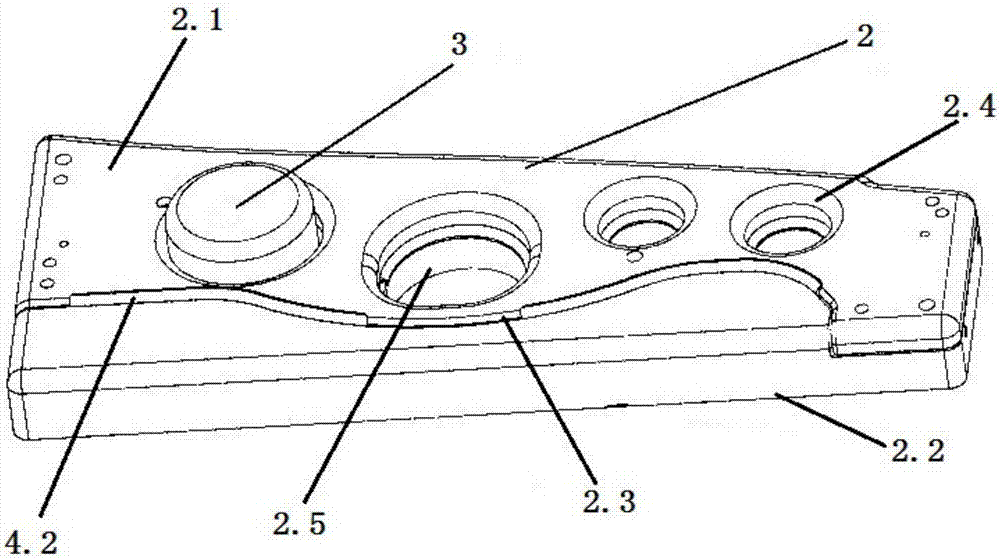

[0023] Such as Figure 2-3 Shown is a forming device for a small height flanged part 4, the part 4 has a main body 4.1, the edge of the main body 4.1 has several arc-shaped flanges 4.2, several straight flanges 4.3, and the main body 4.1 has several Flange hole 4.4, including the first type tire, the second type tire and the core 3;

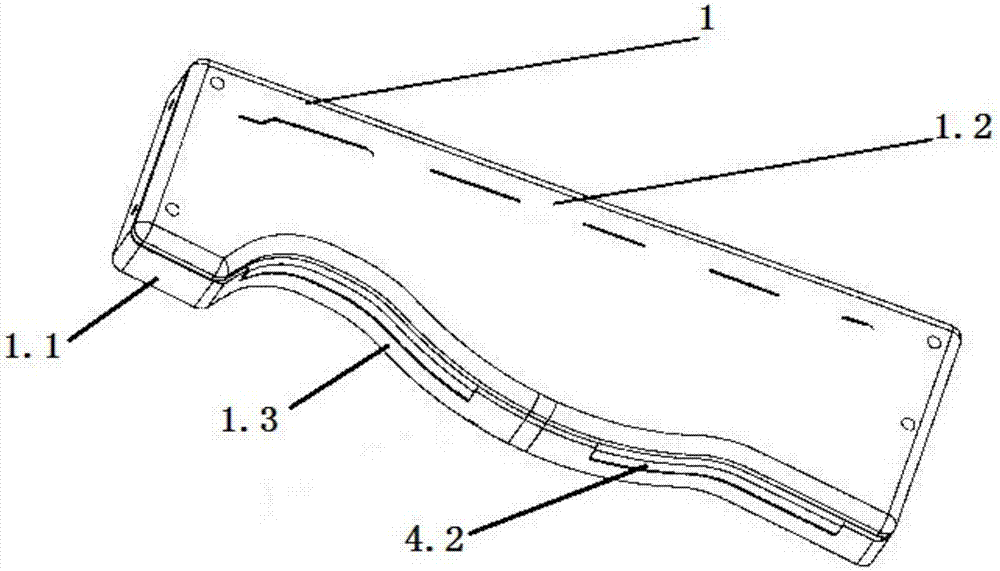

[0024] Such as figure 2 The shape of the first type tire shown matches the shape of the main body 4.1 after the part 4 is formed, that is, the cross section of the first type tire matches the main body 4.1 of the part 4; one side of the first type tire is an arc-shaped surface I1.3, the curvature of the arc-shaped surface I1.3 matches the curvature of the arc-shaped flange on the part 4; the first-type tire is divided into upper and lower parts, which are respectively the first-type tire cover 1.2 and The first type tire carcass 1.1; when forming, the main body 4.1 of the part 4 is located between the first type tire tire cover 1.2 and the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com