Filter support seat, pouring system and pouring method

A pouring system and filter technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of unblockable, increased sand box height, and no positioning, etc., to reduce production costs, reduce costs, and reduce operations effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

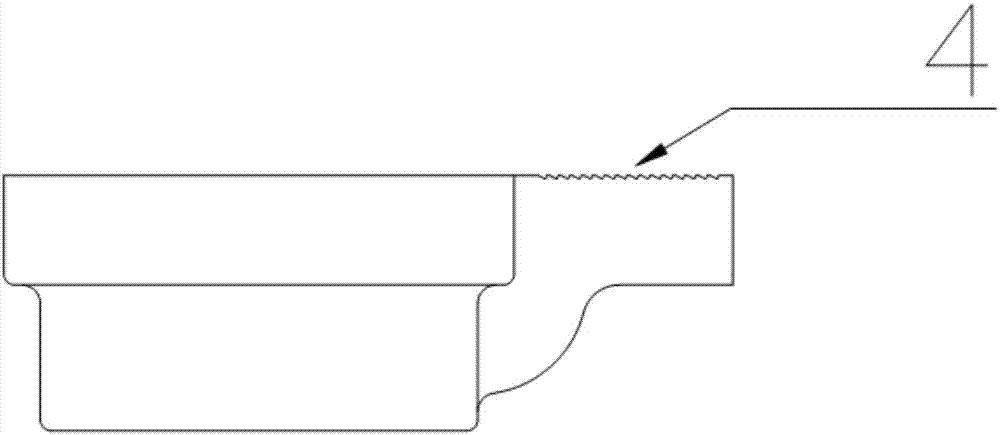

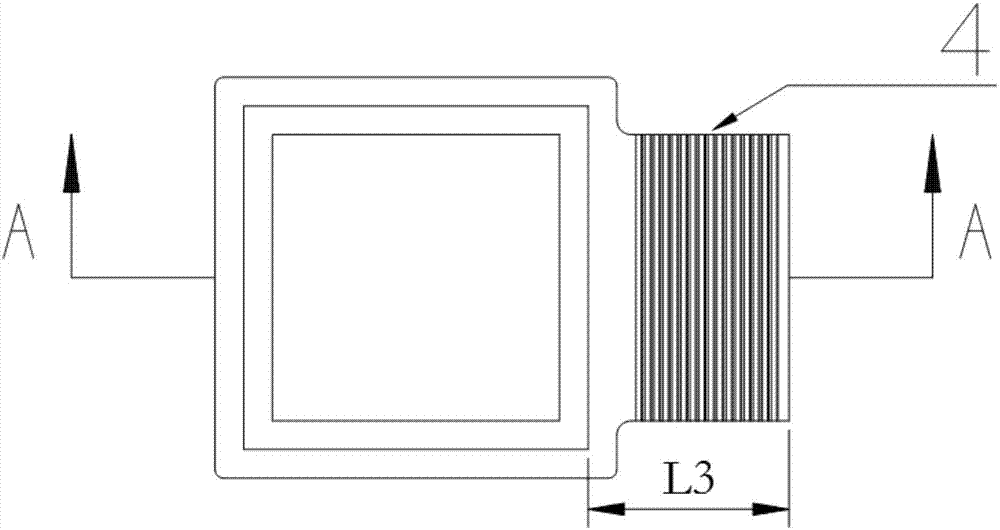

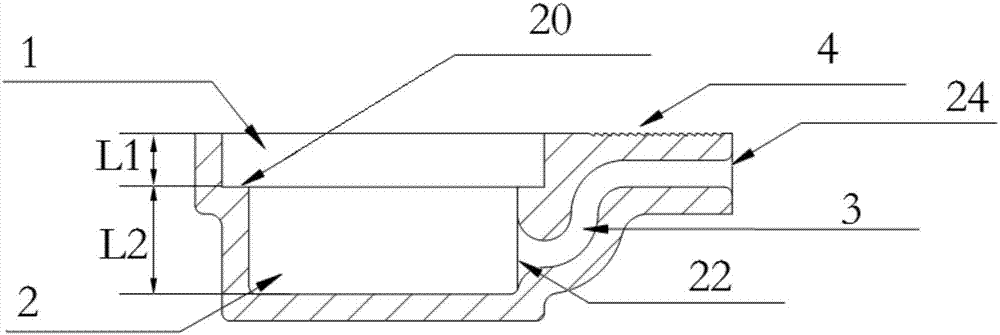

[0027] Such as Figure 1 to Figure 3 As shown, the present invention provides a filter support seat on the one hand, including: a filter screen placement port 1 for placing the filter screen; a molten iron slow flow chamber 2 located inside the filter screen support seat, the molten iron slow flow chamber 2 and the filter The net placement port 1 is in communication; and the molten iron flow channel 3 is used to communicate the molten iron slow flow chamber 2 with the external cavity.

[0028] It should be noted that, in the above-mentioned embodiment, the filter screen support seat is configured such that the molten iron passes through the filter screen placed in the filter screen placement port 1 to filter, then enters the molten iron slow flow chamber 2, and then enters the outside through the molten iron flow channel 3 cavity. Of course, in addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com