Method for continuous casting billet two-stage continuous and dynamic heavy downward pressing

A continuous casting billet and heavy pressing technology is applied in the field of continuous casting production to achieve the effects of improving the segregation defects of the billet, improving the center porosity and increasing the density of the billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

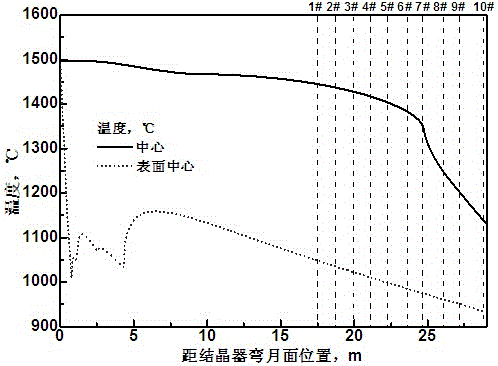

[0030] In this example, the section size of a bloom continuous casting machine is 380mm×490mm, and there are 12 tension-leveler frames in the air-cooling zone. When the casting speed of 0.45m / min is used to cast bearing steel GCr15, the starting point of pressing is located at 3# tension-leveler At the position, the change diagram of the center temperature inside the bloom and the center temperature on the surface is as follows figure 1 shown, from figure 1 It can be seen that the end point of the reduction is at the position where the temperature difference between the inner center temperature and the surface temperature of the slab is ≤200°C, that is, at the 9# tension leveler, and the solidification end point is located between the 7# and 8# tension leveler frames;

[0031] The first stage of reduction is 3#-6# tension leveler, and the second stage of reduction is 7#-9# tension leveler. The distribution of the reduction of each tension leveler is shown in the table below....

Embodiment 2

[0036] The section size of a wide and thick plate continuous casting machine is 280mm×1800mm, and the horizontal section is composed of 5 fan-shaped sections, namely the 9#-13# section. The segment length is 2.1m, and when Q345 is produced at a casting speed of 0.85m / min, the solidification end point is within the 10# segment;

[0037] The first stage of reduction is 9# segment, the second stage of reduction is 10#, 11# segment, and the reduction amount of each segment is set as shown in Table 2.

[0038] Table 2 The reduction process of each segment (mm)

[0039]

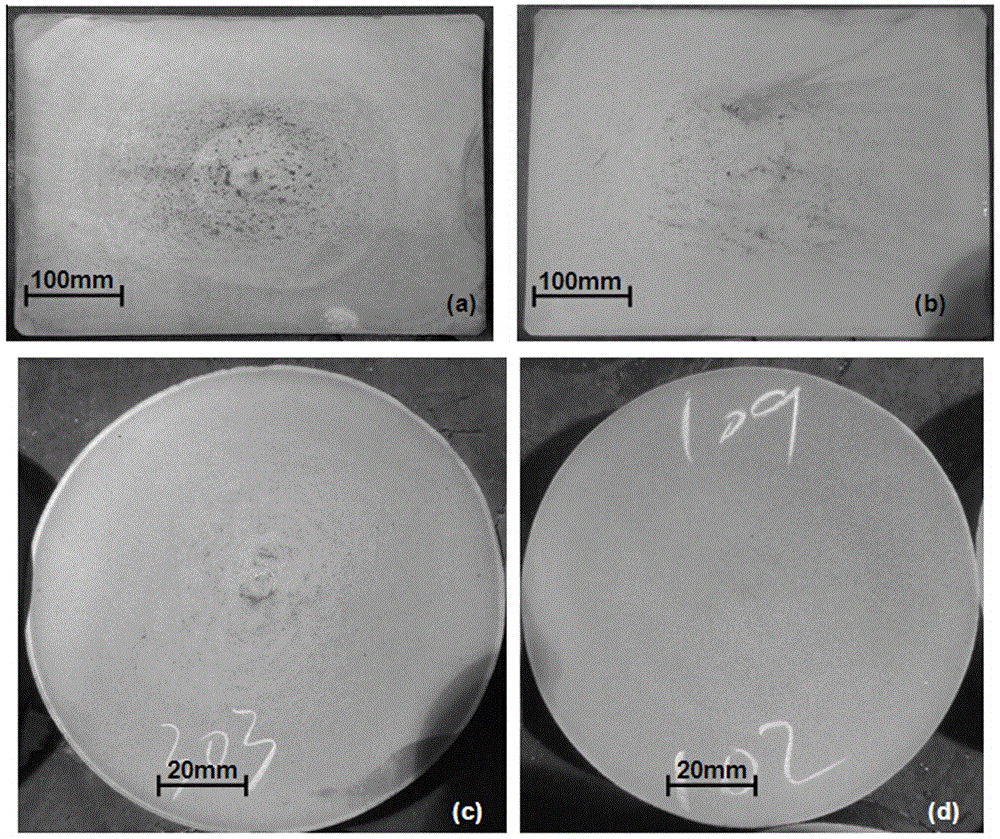

[0040] In this example, the wide-thick slab under two-stage heavy pressing and the wide-thick slab without two-stage heavy pressing are compared in the low-magnification cross-section at the 1 / 4 position in the width direction. image 3 shown, from image 3 It can be seen that the internal quality of the slab is significantly improved after the implementation of the two-stage continuous dynamic heavy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com