Welding device for garbage truck padding device bottom arc plate

A welding device and filler technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problem of affecting the dimensional consistency and stability of filler parts, affecting the speed of bottom arc plate welding production, and the lack of welding quality. Guarantee and other issues, to achieve the effect of quick clamping, positioning and splicing, simple structure, and eliminating the interference of the filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

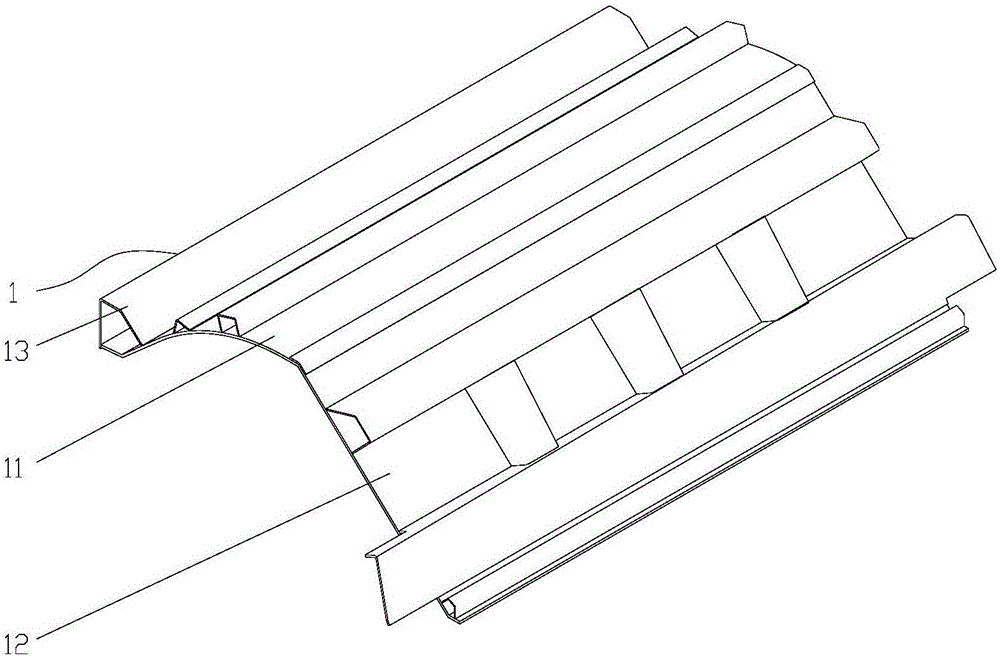

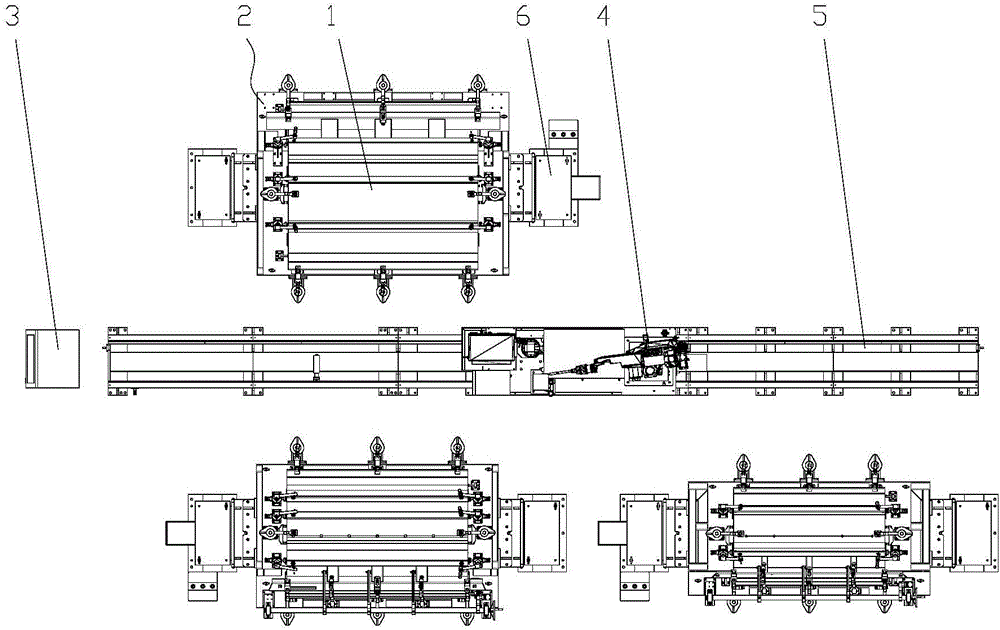

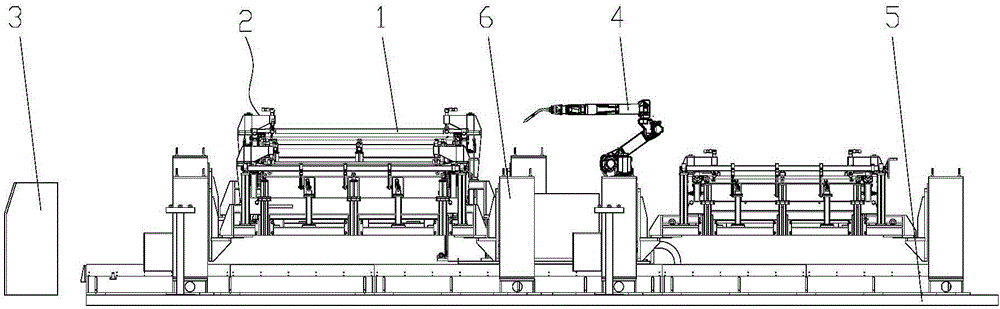

[0021] Such as Figure 1-5 As shown in one of them, a welding device for the bottom arc plate of a garbage truck filler, the bottom arc plate 1 is at least made up of an arc plate 11 and a bent plate 12 by tailor welding, and the welding device at least includes A welding jig 2, the welding jig 2 includes a stepped base 21 with an upper step 211 and a lower step 212, the upper step 211 is provided with a curved surface support 22, and the side of the curved surface support 22 away from the lower step 212 is provided with a A plurality of first positioning protrusions 221 on one side of the positioning arc-shaped plate 11, a pair of first pressing mechanisms 23 for positioning and pressing the arc-shaped plate 11 are provided at both ends of the upper step 211, and on the lower step 212 An inclined plane support 24 is provided, and the other side of the inclined plane support 24 away from the upper step 211 is provided with several second positioning protrusions 241 for positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com