Automatic assembling mechanism for automobile safety belt locking ratchet wheel

A safety belt lock and automatic assembly technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of automatic assembly difficulties, high labor intensity of workers, and easy occurrence of defective products, so as to enhance the competitiveness of enterprises, The effect of high precision and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

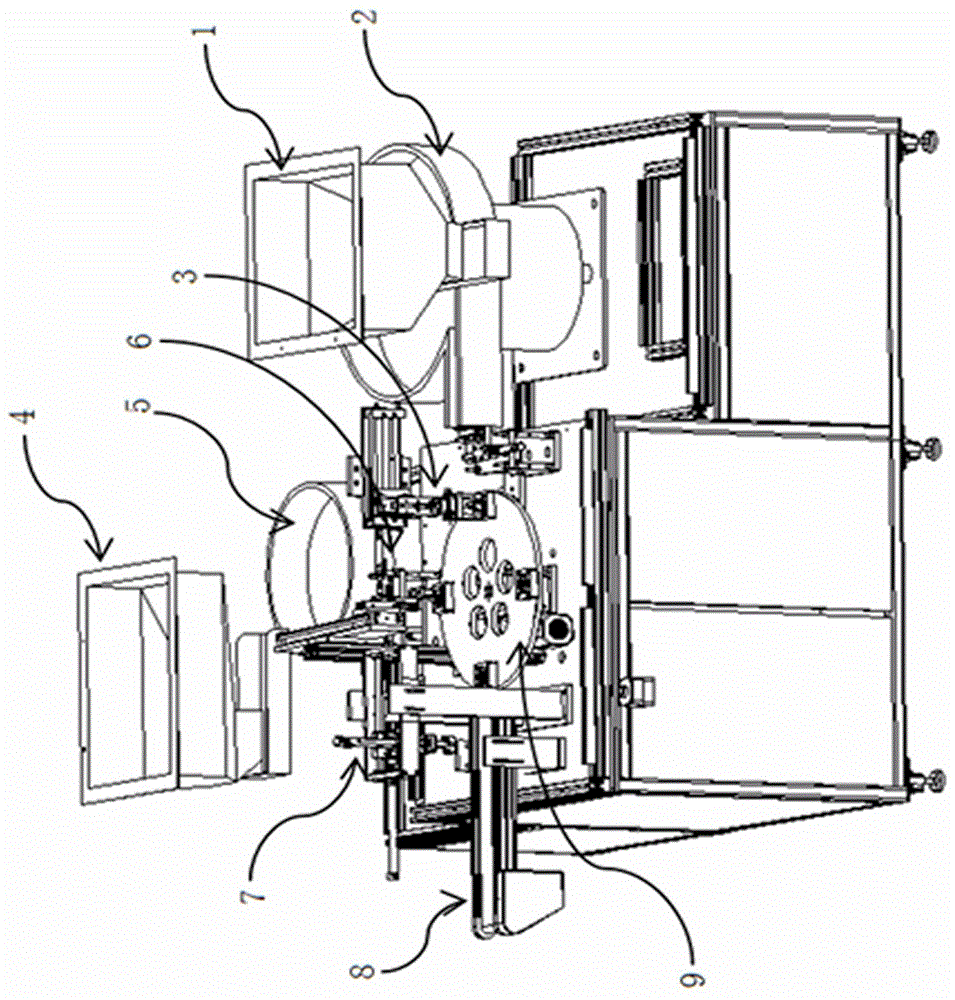

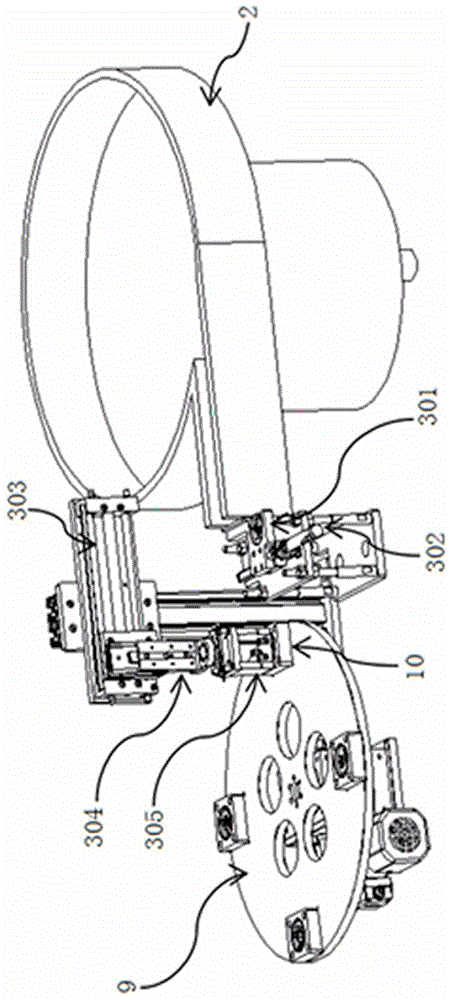

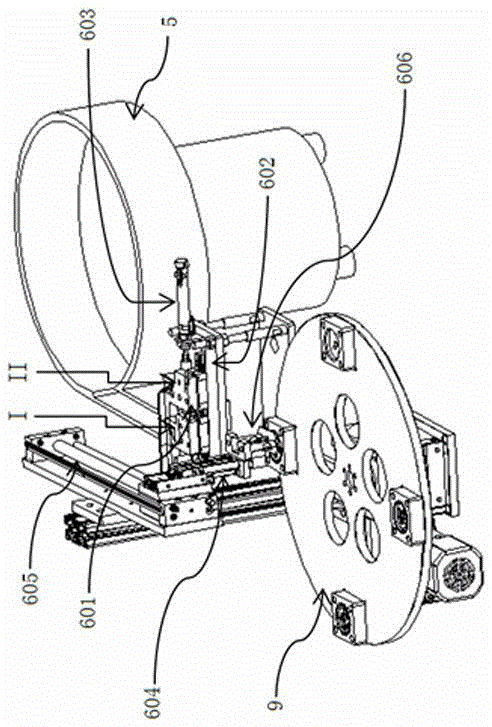

[0019] refer to Figure 1-4 , the specific embodiment adopts the following technical solutions: an automatic assembly mechanism for automobile safety belt locking ratchet, including a feeding mechanism, a rotating mechanism, an assembly mechanism and a discharging mechanism, and the described feeding mechanism is composed of the automatic feeding system of the ratchet and The ratchet automatic feeding system consists of ratchet automatic feeding system including ratchet bin 1, ratchet vibration plate 2, ratchet transfer manipulator 3, ratchet automatic feeding system includes ratchet bin 4, ratchet vibration plate 5. The assembly mechanism includes a pawl grabbing manipulator and a pressing mechanism 6. The discharge port of the ratchet bin 1 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com