Initiative mild grinding and polishing device and method based on viscous-elastic material

An active compliance and viscoelastic technology, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem of uneven removal, inaccurate positioning of polishing tool heads, polishing tools and Problems such as poor fit of the workpiece, achieve high-precision active and smooth grinding and polishing, strong practicability, and improve the effect of effective position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with accompanying drawing:

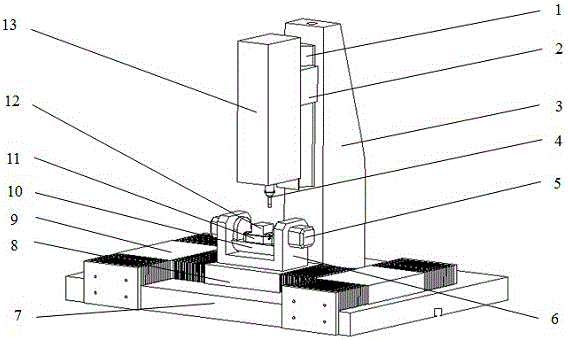

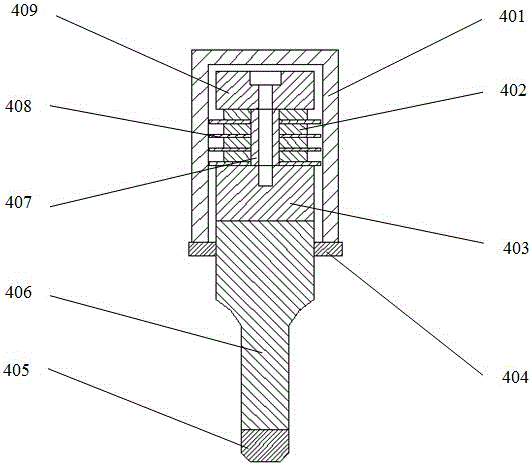

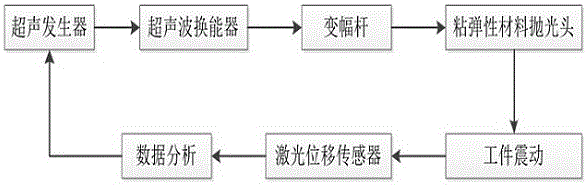

[0022] Such as figure 1 As shown, the active compliance polishing device for viscoelastic materials of the present invention is composed of marble slab 7, support beam 3, ultrasonic vibration system 4, laser displacement sensor, pneumatic guide rail in XYZ direction, workbench 12 and other parts.

[0023] The workpiece is stuck in the center of the table 12, and the requirements for processing complex curved surfaces are met by adjusting the poses of the oscillating table 10 and the rotating table 11 below the table 12. The motors 5 on both sides of the base 6 of the oscillating table 10 and the rotating table 11 are driven .

[0024] The X-direction air bearing guide rail 8 realizes the X-direction stroke feed of the workpiece, and the Y-direction stroke feed of the workpiece is precisely controlled by the double parallel axis Y-direction air bearing guide rail 9, and the air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com