Variable-length bendable fully-flexible mechanical arm structure

A fully flexible, robotic arm technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

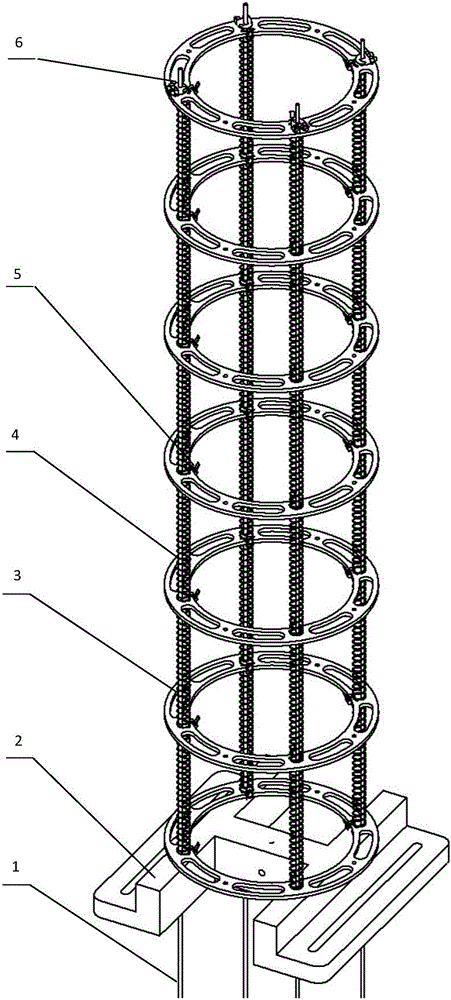

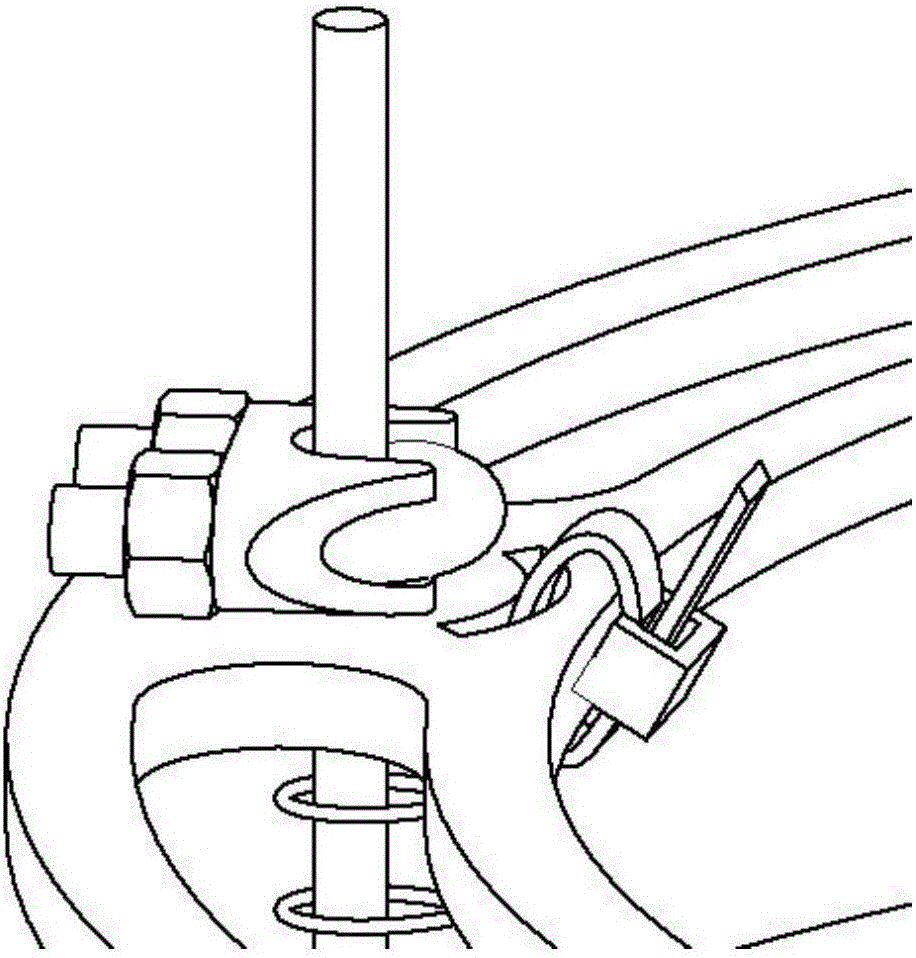

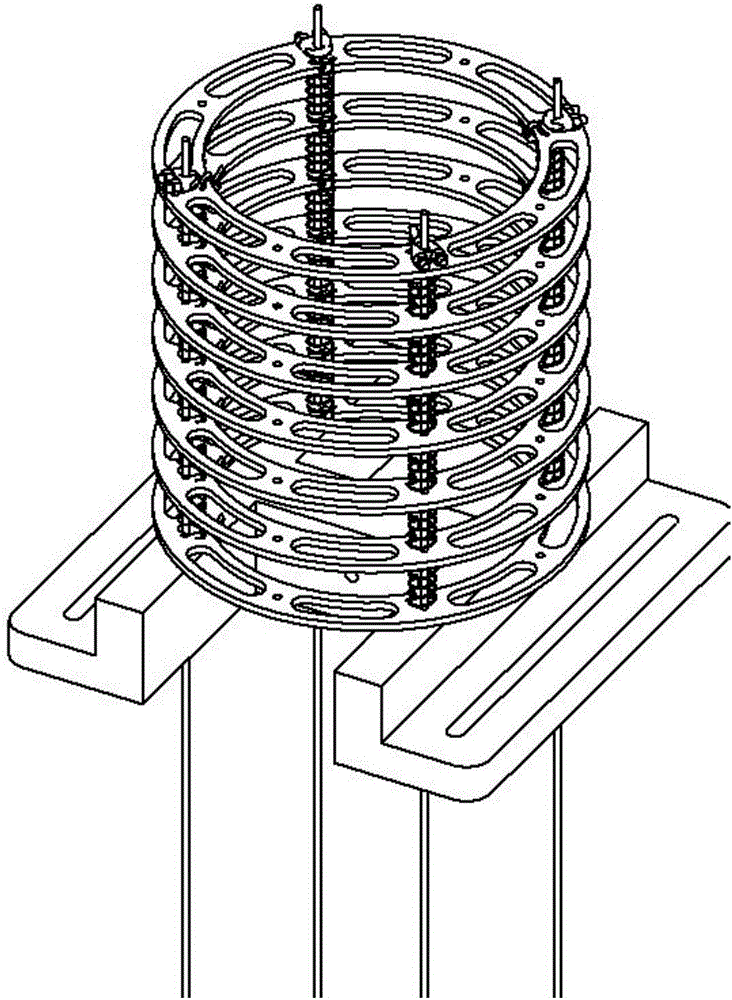

[0018] Such as figure 1 As shown, a variable-length curved fully flexible manipulator structure includes an elastic rod 1 , a base 2 , a metal segment 3 , a spring 4 , a cable tie 5 , and a U-shaped buckle 6 .

[0019] The elastic rod 1, the base 2, and the metal segment 3 are the flexible supporting parts of the structure, the spring 4 is the flexible deformation part of the structure, and the cable tie 5 and the U-shaped buckle 6 are the fastening and locking parts of the structure.

[0020] Each metal segment 3 is a hollow circular segment, and each metal segment 3 is arranged along a vertical direction. A mounting hole capable of passing through the elastic rod 1 is provided on the circumference of the metal segment 3 .

[0021] Each vertically arranged elastic rod 1 passes through the installation hole on the metal segment 3 respectively, and the elastic rod 1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com