Natural ultra-thin stone heat-preserving composite plate and manufacturing method thereof

A thermal insulation composite board and stone technology, applied in stone processing equipment, stone processing tools, manufacturing tools, etc., can solve the problems of low efficiency, limited thinning, waste of materials, etc., and achieve high efficiency, thin stone parts, and processing way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

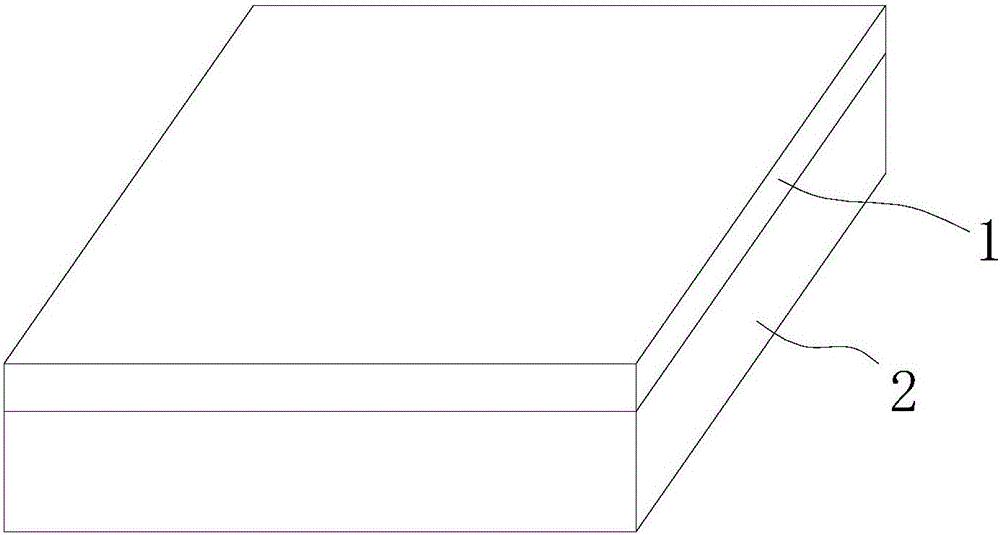

[0036] Such as figure 1 , a natural ultra-thin stone thermal insulation composite board, which includes:

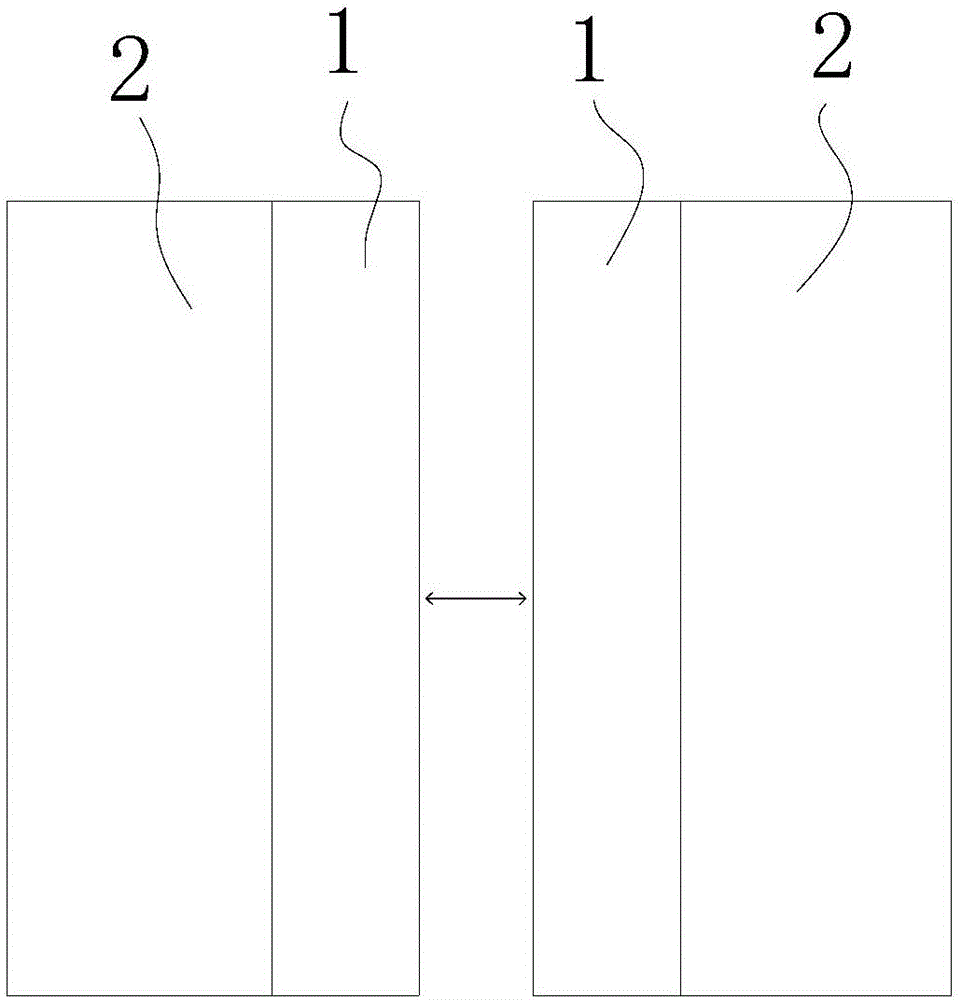

[0037] Natural stone layer 1, the natural stone layer 1 is plate-shaped, with a thickness≤6mm. In this embodiment, the natural stone layer 1 is granite or marble, and its thickness X satisfies: 1mm≤X≤6mm (the If the natural stone layer 1 is made of granite, its thickness Y satisfies: 2mm≤X≤6mm);

[0038] reinforcement layer;

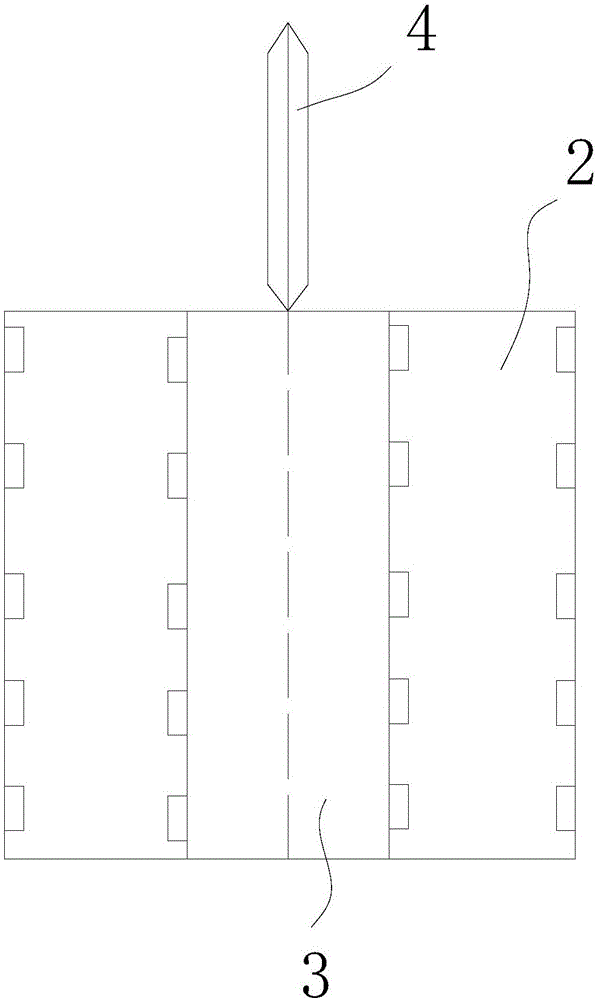

[0039] Insulation material layer 2 (the insulation material layer can be molded polystyrene foam board, extruded polystyrene foam board, polyurethane rigid foam board, thermosetting resin modified polystyrene foam board or rock wool board), so Both sides of the thermal insulation material layer 2 are provided with reinforcement layers, wherein the reinforcement layer on one side is bonded to the natural stone layer 1, and the natural stone layer 1 is connected to two symmetrically arranged thermal insulation layers by the stone material 3 to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com