Double-layer flow guide material storage type die head device of blowing machine

A blow molding machine, double-layer technology, applied in the field of double-layer diversion material storage type die head device, can solve the problems of manufacturing difficulty, long manufacturing cycle, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

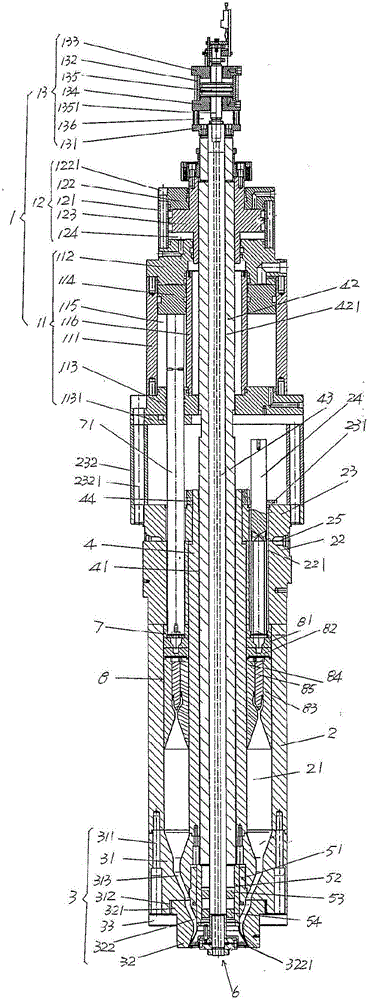

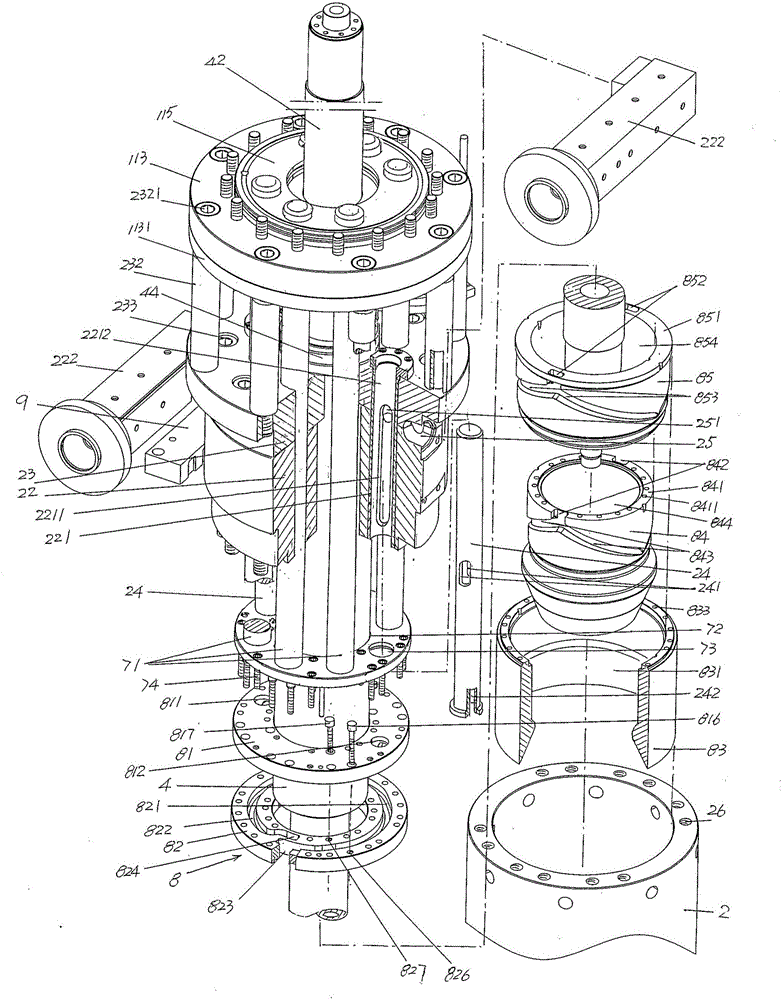

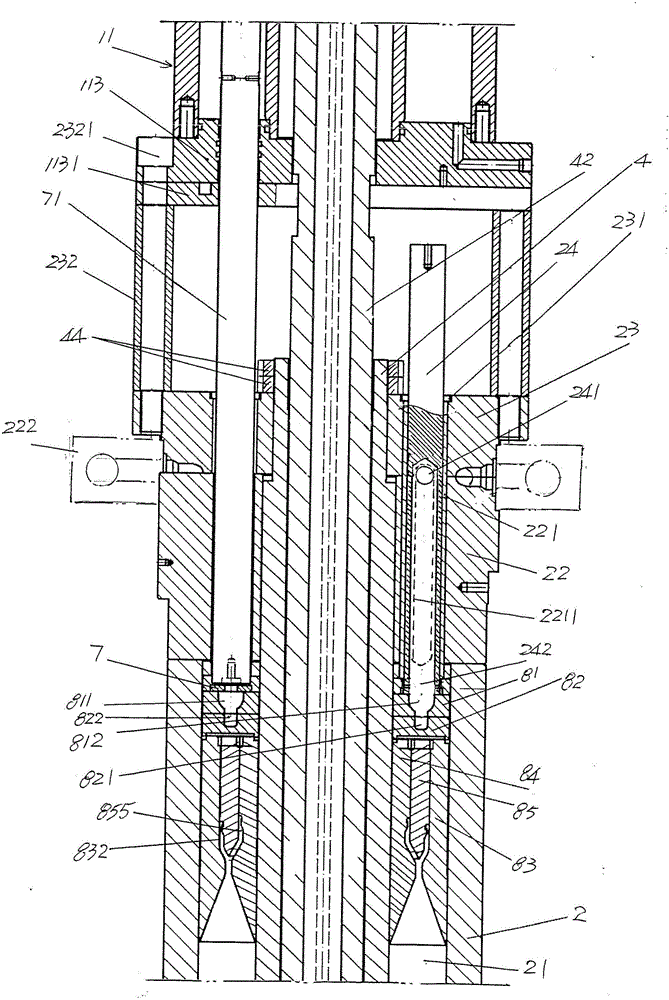

[0029] See figure 1 , which shows a double-deck diversion storage type die head device for a blow molding machine, including a drive mechanism 1; a storage tank 2, which has a storage tank chamber 21, in the storage The top of the tube 2 is fixed with a storage tank cover 22 at the top, and the top of the storage tank cover 22 is also fixedly connected to the cover screw 233 by the storage tube ( figure 2 Schematic) There is a storage tank fixed connection cover 23 fixed, and the storage tank fixed connection cover 23 is fixedly connected with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com