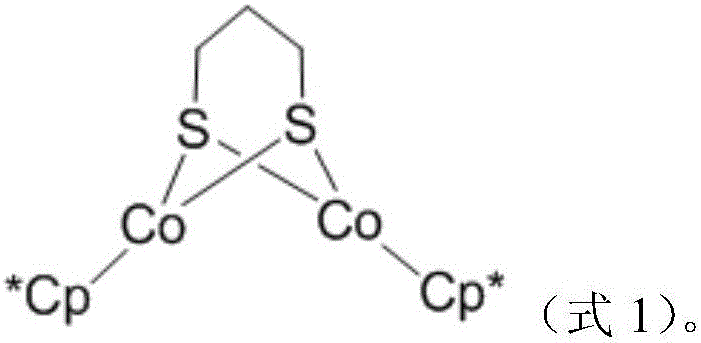

Dinuclear cobalt compound and application thereof in underground catalytic reforming viscosity reduction of heavy oil

A technology of cobalt compound and viscosity reduction, which is applied in the field of binuclear cobalt compound and its application in heavy oil underground catalytic upgrading and viscosity reduction, which can solve the problems of poor catalytic effect, limited contact with crude oil, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a kind of binuclear cobalt compound, and the preparation step of this compound comprises:

[0037] Add n-butyllithium (178 ml of 2.8 mol / L n-hexane solution) to a solution of Cp*H (68 g) in tetrahydrofuran (1000 ml) at -78°C, and raise the temperature to 20°C within 2 hours after the addition is complete. and maintained at 20°C for 2 hours to obtain a reaction solution A containing Cp*Li;

[0038] Cool the reaction solution A to -78°C, then add anhydrous cobalt chloride (64 g), gradually raise the temperature to 0°C after the addition, and keep the temperature at 0°C for 2 hours to obtain the reaction solution B;

[0039]Cool the reaction solution B to -78°C, then add 1,3-propanedithiol dilithium salt (27 g), maintain the reaction at -78°C for 1 hour after the addition, and then rise to room temperature to obtain the reaction solution C;

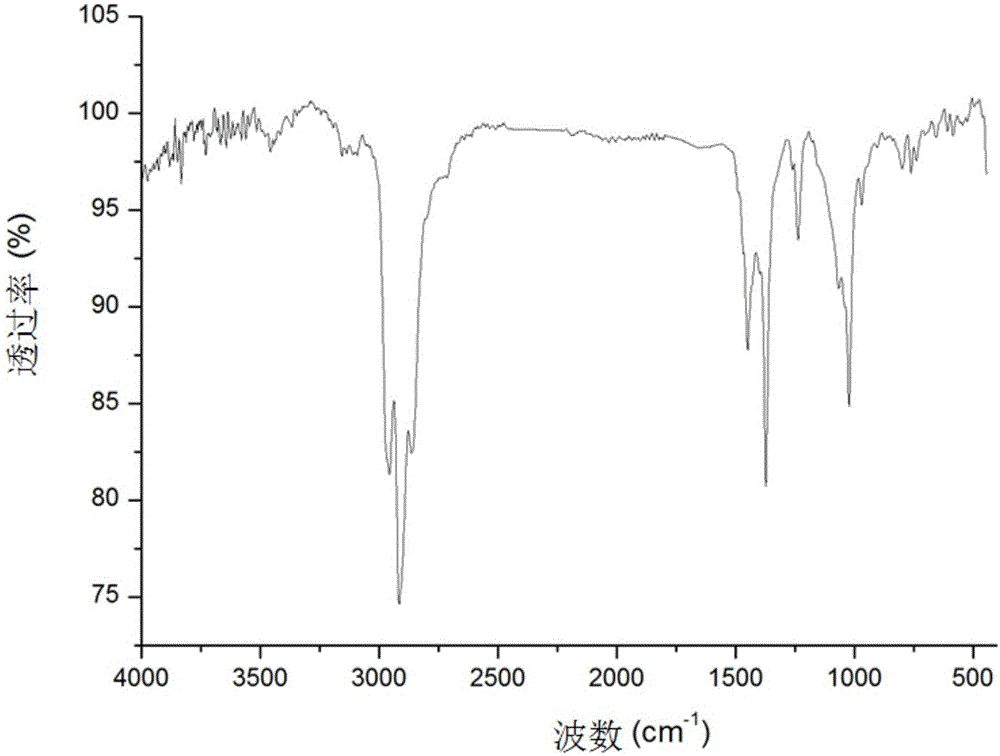

[0040] The reaction solution C is subjected to vacuum distillation to remove the solvent, and then n-hexan...

Embodiment 2

[0045] This example provides an application of the binuclear cobalt compound prepared in Example 1 in the underground catalytic upgrading and viscosity reduction of heavy oil, which specifically includes the following steps:

[0046] (1) Mix 50 grams of Z32 heavy oil with 0.5 grams of binuclear cobalt compound Placed in a 250ml reactor;

[0047] (2) Replace the reactor with nitrogen for 3 times, then heat up to 100°C, and stir at this temperature for 15 minutes;

[0048] (3) Linearly increase the temperature to 300° C. within half an hour, and stop the reaction after the reforming reaction at this temperature for 8 hours.

[0049] Test steps:

[0050] Cool the thick oil after the reaction to room temperature, take out the modified sample, and test the viscosity of the sample at 50°C with a Haake rheometer.

[0051] Test results: Viscosity of heavy oil decreased from 35805mP·s before modification to 5335mP·s, and viscosity reduction rate was 85.1%. It can be seen that the ...

Embodiment 3

[0061] This example provides an application of the binuclear cobalt compound prepared in Example 1 in the underground catalytic upgrading and viscosity reduction of heavy oil, which specifically includes the following steps:

[0062] (1) Mix 50 grams of Z32 heavy oil with 0.5 grams of binuclear cobalt compound Placed in a 250ml reactor;

[0063] (2) Replace the reactor with nitrogen for 3 times, then heat up to 100°C, and stir at this temperature for 15 minutes;

[0064] (3) Linearly increase the temperature to 250° C. within half an hour, and stop the reaction after the reforming reaction at this temperature for 8 hours.

[0065] Test steps:

[0066] Cool the thick oil after the reaction to room temperature, take out the modified sample, and test the viscosity of the sample at 50°C with a Haake rheometer.

[0067] Test results: Viscosity of heavy oil decreased from 35805mP·s before modification to 15970mP·s, and viscosity reduction rate was 55.4%. It can be seen that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com